GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Air Operated Pneumatic Three-phase DC Projection Welding Machine

DESCRIPTION

Medium frequency inverter spot welding machine is an advanced welding machine with wide application. The welding transformer is in small size but the output energy is large. Three-phase AC will be converted into DC after being rectified. Then the DC will be converted into medium frequency 1000 Hz square wave to be connected to primary welding transformer through the inverter circuit which is composed of IGBT. The MF square wave will become small pulse DC to the electrode for welding work piece through the depressurization and rectifying process in the welding transformer. The inverter will adjust the duty ratio of IGBT through the feedback primary or secondary current so as to achieve constant current of the welding process.

Compared with the normal AC controller, MF controller has the following advantages:

1. The current in secondary welding loop is DC. Dramatically reduce the impact to the welding current due to the inductive reactance in secondary loop when conducting welding to the work piece.

2. The weight of transformer is reduced greatly. It is light and convenient. The weight and size of the MF transformer is only 1/3 of the AC type transformer. Suitable for robot welding system.

3. Prolong the service life of electrode

4. Be able to weld material like aluminum, galvanized steel, etc. with good welding performance.

5. Especially suitable for three-layer plate welding, ultrathin material welding and precision welding.

6. Less splashes.

7. Increase control of current and welding quality.

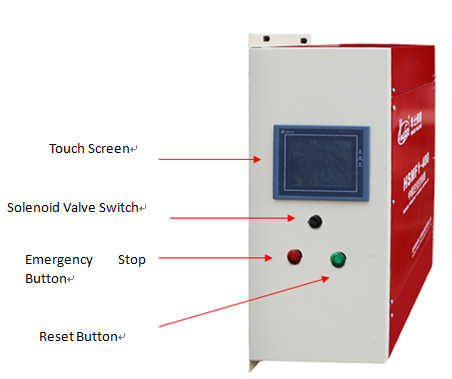

Touch Screen | Central part of operation for input data, monitoring and storage |

Solenoid Valve Switch | Manual switch on or off |

Emergency Stop Button | When start, it will end the entire running program. Note: after pressing this button, you need to power on the machine again. |

Reset Button | After stopping the program, press this button to reset. |

SPECIFICATION

| No. | Item | WL-MF100K |

| 1 | Input Voltage | 380V three-phase |

| 2 | Input Current | 130A |

| 3 | Air Switch | 150A |

| 4 | Power Line(Copper Line) | 25mm ² |

| 5 | Output Voltage | DC9.2V |

| 6 | Max Welding Current | 28kA |

| 7 | Welding Model | 101 types |

| 8 | Different Welding Current | 101 types |

| 9 | Mobile Feeder Length | 16400mm |

| 10 | Feeder Moving Speed | 800mm/sec |

| 11 | Feeder Moving Force | Servo Motor |

| 12 | Cooling Water Pressure | ≤0.2MP |

| 13 | Cooling Water Flow | 20L/min |

| 14 | Cooling Water Temperature | ≤20℃ |

| 15 | Dimension of Machine | 1200mmx16400mm |

***********************************************************************************************

We can design and manufacture the welding equipment according to your request/drawing, contact us please, we will offer you a suit solution and support you to success.

APPLICATION

Especially suitable for welding metals such as copper, aluminum, nickel, molybdenum, tungsten, manganese, gold, silver and other non-ferrous metals and precious metals precision. Widely applied to welding battery, lighting electric resource automobile, medical apparatus and instruments, photoelectric communication, micro motor as well as requested chip inductor with high temperature enameled round wire/ extra fine wire (minimum size can be 0.02mm),wire rope, metal wire, nickel cup, can cutting wire and welding, CCFL field, fuse, lamp filament.

FEATURE

1. The current in secondary welding loop is DC. Dramatically reduce the impact to the welding current due to the inductive reactance in secondary loop when conducting welding to the work piece.

2. Three-phase balanced load can reduce the requirement to the

power supply system. The power factor is close to 1. No electrical

inductance, so no need to adjust the power factor.

3. Eradicate the contamination to the power supply. It is a kind of

environmentally friendly welding method. No need to provide power

independently. It is able to be used together with robotic welding

system.

4. Reduce power consumption, energy saving. Reduce the requirement

of cables and lots of maintenance cost.

5. The weight of transformer is reduced greatly. It is light and

convenient. The weight and size of the MF transformer is only 1/3

of the AC type transformer. Suitable for robot welding system.

6. Increase the heat input efficiency. The output of welding

transformer is DC voltage, without the disturbance of inductance.

Pure DC has no defect of zero passage. The efficiency of heat is

enhanced dramatically.

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.