GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

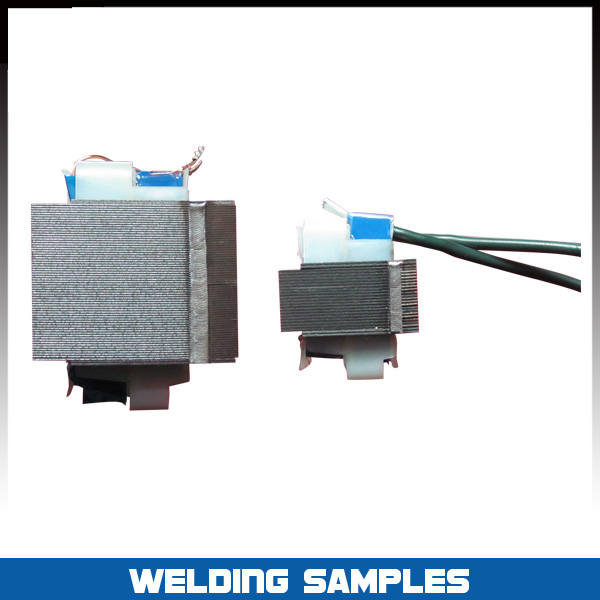

WL-LA-250A Transformer EI Piece Automatic MIG Tig Welding Machine

DESCRIPTION

The machine is used to automatic welding and assembly for transformer E, I lamination .

1. After assembly of the E piece and I piece, the electric reactor will enter into feeding conveyer belt, then enter into horizontal feeding cylinder area under the effect of adjustable-speed motor.

2. The horizontal feeding cylinder will action, pushing the work piece into vertical feeding cylinder area.

3. Afterwards, the vertical feeding cylinder will action, pushing the work piece into flat welding area. The left and right leveling cylinder will level off the work piece and compress it. The upper cylinder will action to compress the work piece.

4.In order to achieve higher automatic, we designed the machine with feeding and discharging conveyer belt. It can help to save more labor force and increase production rate.

SPECIFICATION

Item | Parameters |

Input Voltage | 380V three-phase |

Input Current | 15A×3 |

Argon Arc Welder | 315A |

Servo Motor Moving Disctance | ≤75mm |

Welding Gun Moving Speed | ≤0.5m/sec |

Vertical Feeding Cylinder | ¢40x400mm |

Upper Clamping Cylinder | ¢50x50mm |

Left and Right Leveling Cylinder | ¢40x50mm |

Discharging Cylinder | ¢40x150mm |

Conveyer Belt Length | 1200mm |

MACHINE COMPOSITION

1. Power Source System: Japan Panasonic AC DC 315 argon arc welder as the welding power source.

2. Pressurized and Locating Mechanism: Adopt the South Korea SANWA pneumatic parts as the pressing source of the machine. Adopt the working manner that the bottom bears the stress from the top to guarantee the reasonable machine structure and quick locating mechanism to conduct locating function.

3. Mobile System: The mobile welding distance is designed as 75mm. Since the mobile stability and constant speed is of quite importance, so the machine is designed as servo motor as the driving force. Besides, it is equipped with finish machining good quality slide way and driving screw.

4. Control System: Adopt Japan Panasonic PLC as the control hub of the whole machine, is in charge of reading, transmitting and controlling all kinds of signal processing and coordinating with various external instructing transmission signal mechanism in order to ensure the validity of all orders of execution of the machine. Simple testing and operation. The welding spot distance and welding speed can be set through the menu easily.

5. Detection System: Use Omron optical fiber detection device together with alarming device. Effectively ensure the normal working of the system.

APPLICATION

Automatic assembly and welding of EI lamination for transformer.

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.