GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

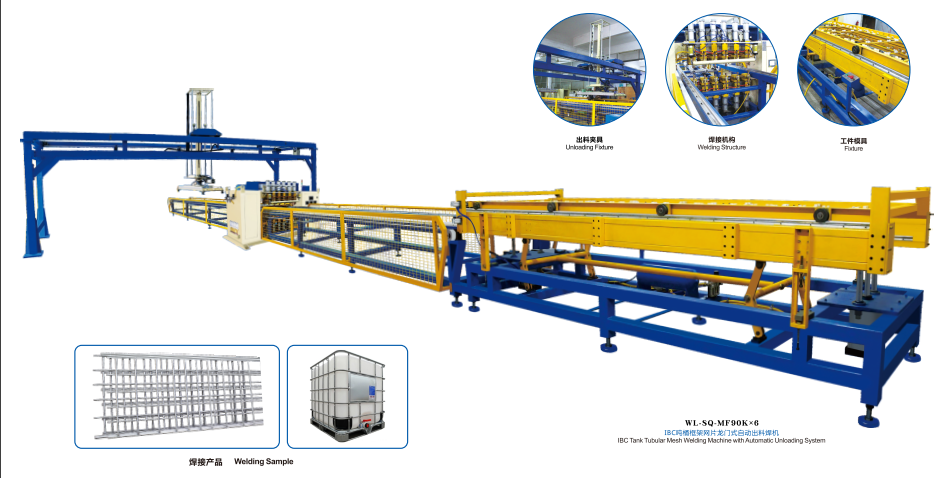

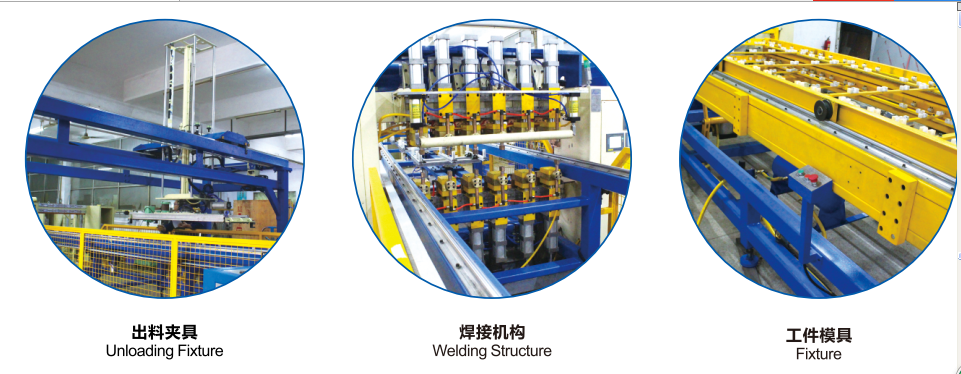

Fully Automatic IBC Container Tank Tote Frame Welding Machine

DESCRIPTION

This machine is special automatic welding for IBC tank wire frame tubular mesh within 4000x1150mm

6-Head Gantry Type Welding Machine is our latest special machine for welding IBC tank tubular frame. The IBC tank is composed of inner container and metal frame. The metal frame is made of bended tubular mesh.IBC intermediate bulk container is an essential tool in modern storage, liquid transportation.

SPECIFICATION

| No. | Model | WL-SQ-MF90Kx6 |

| 1 | Input Power | Three-phase |

| 2 | Rated Capacity | 90KVAx6 |

| 3 | Rated Input Current | 300A |

| 4 | Rated Duty Cycle Rate | 25% |

| 5 | Secondary Voltage Adjusting Grade | 2 |

| 6 | Max Secondary Floating Voltage | 12.5V |

| 7 | Secondary Max Short Circuit Current | 26KA |

| 8 | Continuous Working Current | 20KA |

| 9 | Welding Transformer Insulation Grade | F |

| 10 | Welding Machine Pressuring Curves | 2 types |

| 11 | Welding Programs Number | 101 types |

| 12 | Welding Head | 6 sets |

| 14 | Effective Welding Width | 1000mm |

| 15 | Effective Welding Length | 4000mm |

| 16 | Stepping Welding Moving Speed | 500mm-1000mm/sec |

| 17 | Upper Electrode Stroke | 80mm |

| 18 | Lower Electrode Stroke | 50mm |

| 19 | Unloading Feeder Moving Distance | 500mm |

| 20 | Unloading Feeder Lifting Distance | 1200mm |

| 21 | Unloading Feeder Moving Speed | 500mm-1000mm/sec |

| 22 | Unloading Feeder Rotating Angle | 900 |

APPLICATION

Design for batch production of IBC stainless steel tubular mesh within 4000x1000mm , etc.

MATERIAL CONFIGURATION

1.Adopt silicon controlled from SEMIKRON of West Germany or IXYS of United Stated with high precision and long service life.

2.Adopt integrated circuit from Motorola of U.S. and PLC from Japan SIEMENS with quick response and stable performance.

3.Adopt Japan Panasonic intelligent touch screen control system which is installed with automatic bug alarm system.

4.Adopt self-developed intelligent microcomputer welding control system to control the compensation for the fluctuation of circuit built-in voltage in order to ensure the fluctuation of voltage is within±15%.

5.Adopt South Korea SANWO pneumatic components with stable performance.

6.All the electronic components are from Japan Mitsubishi and Omron with ideal service life and performance.

7.The transformer adopts Japan high purity silicon steel sheet with good magnetic and electricity conductivity.

8.High precision all digital control system effectively resolve the problems of cold joint or loose welding due to the current shunt in projection welding.

9.Strictly comply with CE security standard to design the machine. Lower the accident rate.

Quality Standard

The machine is manufactured according to the following standard.

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO 9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.