Zhuzhou Grewin Tungsten Carbide Tools Co., Ltd |

|

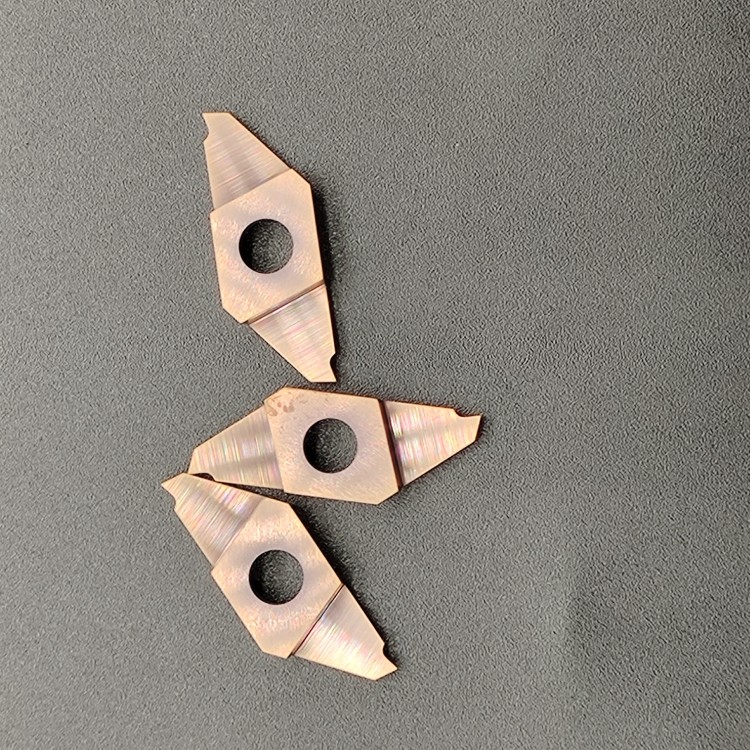

Fine Polished Good Quality Lathe Carbide VCMT 160404 Carbide Turning Inserts

Product Descroption

| Product Name | Fine polished good quality lathe carbide vcmt160404 carbide turning inserts |

| Brand | GW / without name |

| Model | LOGU030310ER-GH |

| Coating | PVD/CVD |

| Material | 100% Virgin |

| Grade | MC115/MC118/MC118X/MC335/MC335X |

| Workpiece | Steel/Stainless steel/Alloy steel/Cast Iron |

| HRA | HRA 89-93 |

| MOQ | 1 |

| Dimensions | |||||

| L | D | S | d1 | R | |

| VCMT110304 | 11.2 | 6.35 | 3.18 | 2.8 | 0.4 |

| VCMT110308 | 11.2 | 6.35 | 3.18 | 2.8 | 0.8 |

| VCMT160404 | 16.6 | 9.525 | 4.76 | 4.4 | 0.4 |

| VCMT160408 | 16.6 | 9.525 | 4.76 | 4.4 | 0.8 |

Product Show

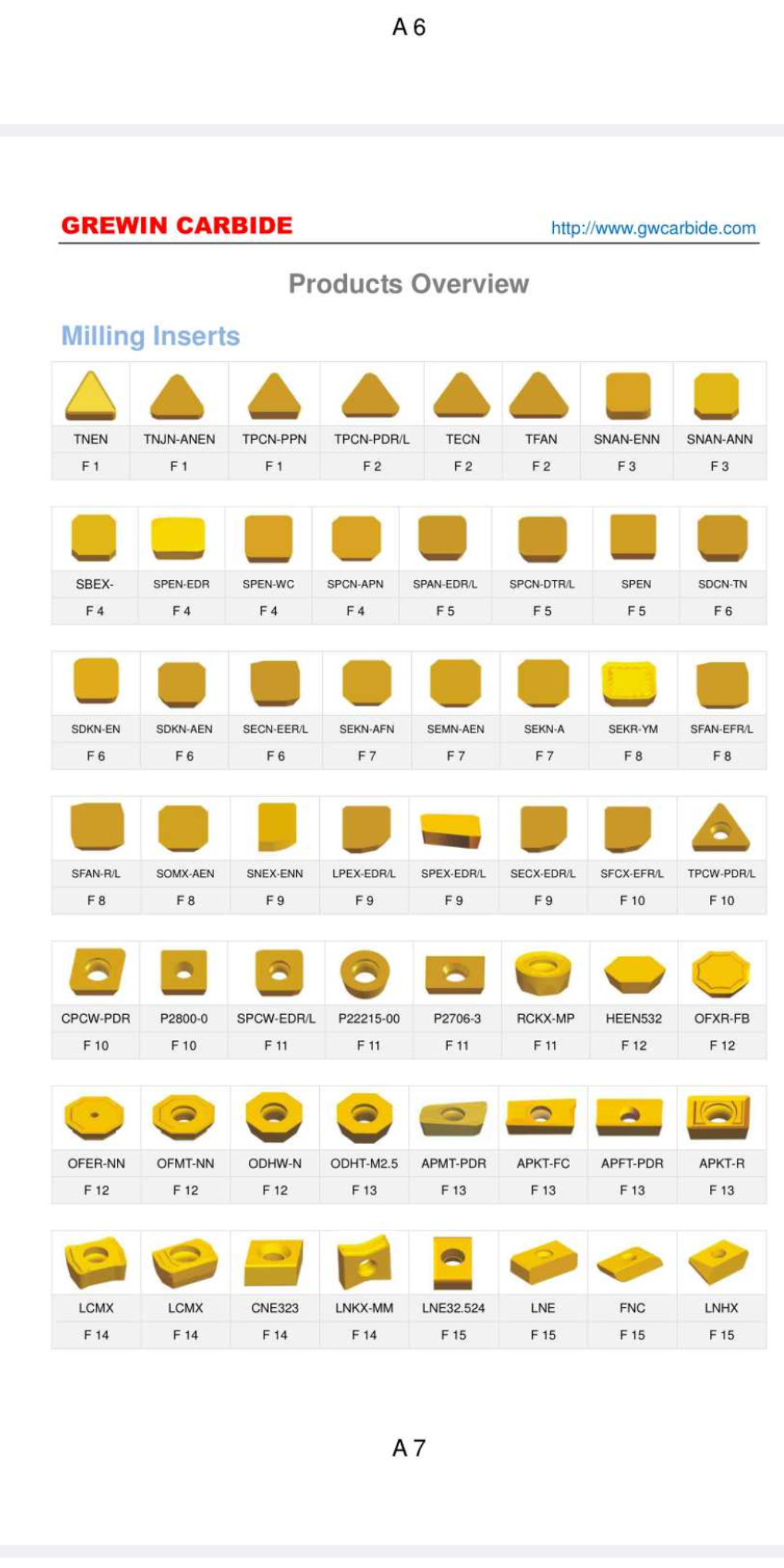

Product Related

1. WARMLYTIPS

01.Properly reducing the cutting speed and feed rate can prolong

the trial life of the milling cutter.

02.When working, it is necessary to add cutting fluid to protect

the cutting edge, which makes the cutting smoother.

03.When there is an oxide film or other hardened layer remaining on

the surface of the work-piece, it can be removed by reversible

milling.

2. INSTRUCTIONS FOR USE

What buyers need to know about end mill selection and operating

instructions

01.Before using the tool, please measure the tool deflection. If

the tool deflection accuracy exceeds 0.01mm, please correct it

before cutting.

02.The shorter the length of the end mill sticking out of the

chuck, the better.If the end mill sticks out for a long time, it is

necessary to reduce the rotational speed, feed rate or cutting

amount.

03.During cutting, if abnormal vibration or sound occurs, please

reduce the cutting speed and the cutting feed rate until the

situation improves.

04.The steel cooling is preferably spray and air jet, which can

effectively improve the use effect of the milling cutter.