Henan Jinzhen Machinery Manufacturing Co.,Ltd. |

|

High Efficient Waste Tyre Pyrolysis To Energy Oil Machine Scrap Tire Recycling Pyrolysis To Oil Plant

waste tyre pyrolysis plant adopt the latest pyrolysis technology and process the waste tyres/plastics with high temperature in a oxygen-free condition. Through the waste tyre pyrolysis process, you can get fuel oil, carbon black, steel wire and combustible gas from waste tyres.

The raw materials can be used tires, waste plastic, scrap rubber which can be easily found from rubbish collecting station. The cost of raw materials is low, even you can get subsidy by solving pollution caused by garbage in many countries. Mean-while the fuel oil has a good market in industry field.

1. The Raw Material For Pyrolysis Machine

| 1 | Waste tyre | Steel tyre ,Nylon tyre ,Bick tyre |

| 2 | Waste plastic | PE,PVC,Waste washed mixture plastic from waste Paper Factory |

| 3 | Waste rubber | Shoes Soles,Cable Skin |

| 4 | oil sludge,waste oil sludge |

2. Pyrolysis plant models and specification

| No. | Item | Contents |

| 1 | Pyrolysis Plant Daily Capcity | 5T/8T/10T/12T/15T |

| 2 | Reactor Size | 2200*6000mm/2800*6000 |

| 3 | Reactor Material | Q345R |

| 4 | Reactor Thickness | 16mm |

| 5 | Total Weight | 25-35T |

| 6 | Running Time | 20-24h |

| 7 | Operating Power | 20KW |

| 8 | Space Needed | About 300 square meters |

| 9 | Labour Needed | 3-4 persons |

| 10 | Raw Material | Waste tire,plastic,rubber,etc |

| 11 | Heating Fuel | Coal,wood,fuel oil,gas,charcoal |

| 12 | Output Product | Fuel oil, carbon black,(steel wire) |

3.The available fuel for pyrolysis processing

| NO. | Fuel |

| 1 | Oil(fuel oil, tyre oil, heavy oil etc..) |

| 2 | Natural gas |

| 3 | Coal |

| 4 | Firewood |

| 5 | Carbon black pellet |

4. End product percentage and useage( Example : raw material is tyre)

| No. | Pyrolysis Plant Output Products | Amount | Application |

| 1 | Fuel oil | 45%-50% | * can be directly sold to boiler factory, cement factory,glass factory etc. * can be refined to diesel. * used as heating fuel.

|

| 2 | Carbon black | 30% | * can be directly sold to cement or brick factory. * can be refined as raw material in many industries. * pellet it used for heating. |

| 3 | Steel wire | 10-15% | * can be pressed and sold to steel and scrap dealers. * make steel blocks by hydraulic baling press. |

| 4 | Waste gas | 5% | used for the heating fuel. |

5. Pyrolysis machine advantage and main technical characteristics

1. Fully automatic horizontal rotation.

2. The degree of mechanization is high.

3.adapt to a wide range of raw materials

4.desulfurization powerful atomization dust removal + vortex dust

removal, dust treatment in line with advanced national

environmental protection requirements.

5. After a thermal cracking secondary catalysis, and then

filtering, the quality of the oil is improved by one grade and can

be directly sold as a commodity.

6. high temperature spray evaporation, low temperature immersion,

the largest advantage of less floor space, easy to clean, good

cooling effect, under normal circumstances do not need to use water

cooling tower.

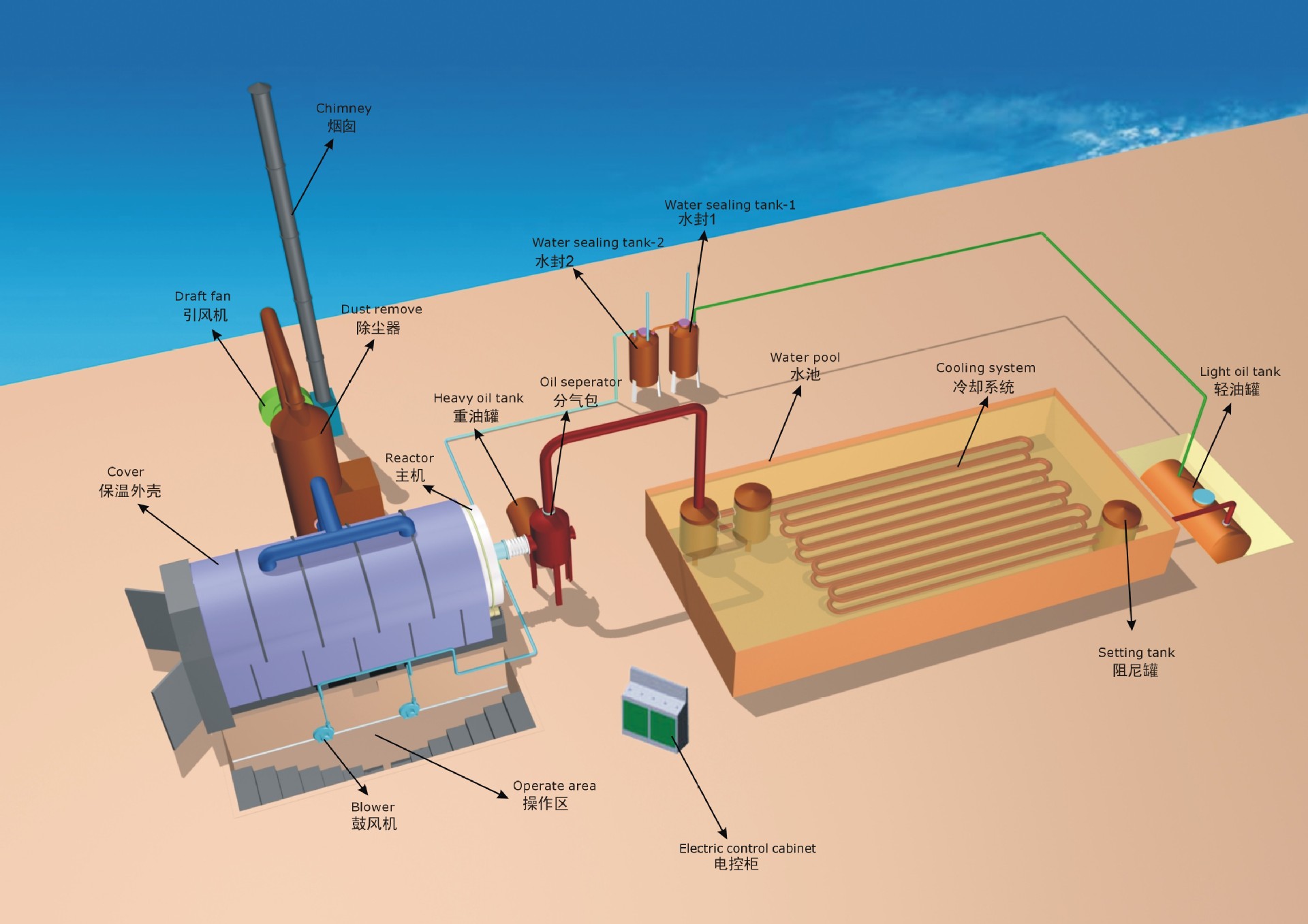

6. Machine 3D drawing flow chart and working processing

Put the raw material into the reactor, and then heat the burner. The oil gas from reactor will be separated in the manifold. The heavy oil gas will drop down and be store in the slag oil tank, while the light gas will rise up to the condenser. After cooling, gas turns into liquid and flows to the oil tank. The remained gas that cannot be liquified will enter the hydroseal, and then return to the burner to be burnt after the edulcoratio and desulfuration

Warranty and service after sale

1.Quality warranty period: One year warranty for the main reactor of pyrolysis machines and lifetime maintenance for complete set of machines.

2.Our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's workers on operation, maintenance, etc.

3. Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.

4. For the damage caused by the users, our company provides the parts and accessories with cost price.

5. Our factory supplies the wearing parts with the cost price to clients.