Shenzhen Jaguar Automation Equipment Co., Ltd |

|

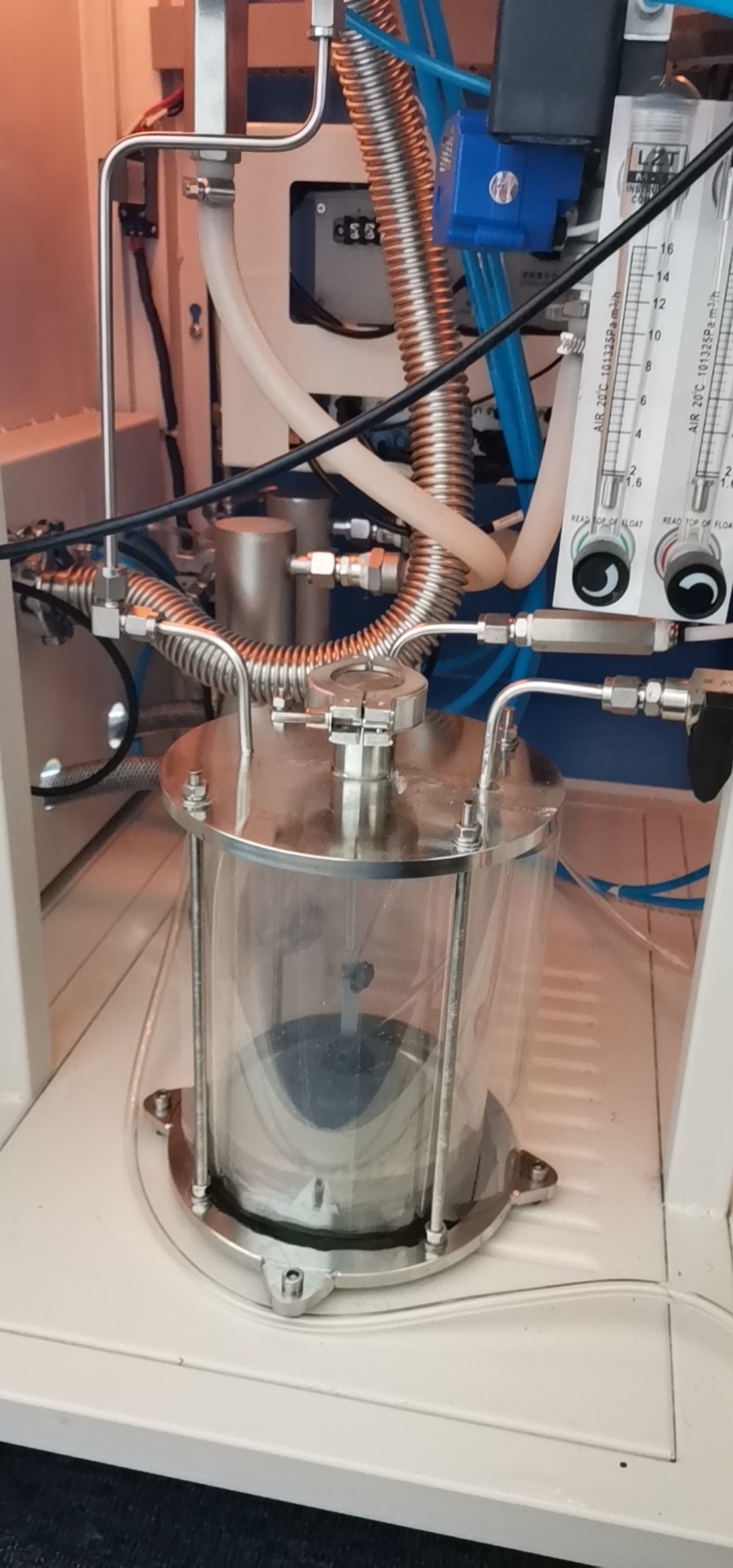

JAGUAR Vacuum Reflow Oven JB-V43

JB-V43's main applications: IGBT Modular, MEMS Package, High Power Device Package, Photoelectric Package, Airtight Package and so on.

JB-V43 is a new type of economical vacuum reflow soldering machine, with universal, high efficiency, full process, high vacuum, enhanced system protection, simple operation and convenient maintenance. Meantime it equipped with multi-angle high resolution video camera, which synchronously records and synchronously displays important technical parameters such as real-time temperature profile and vacuum degree, so as to strengthen the collation and statistics of new product process data and the monitoring and analysis of welding products. Powerful process database, can guide you to find the solution to the problem, different levels of operators can be skilled in equipment process and operation debugging.

Specifications:

| JB-V43 Technical Specifications | ||

Basic Parameter

Basic Parameter | Dimension | 1400 x 800 x 1300 mm (LxWxH) |

| Weight | About 260 kg | |

| Vacuum degree | Below 10Pa | |

| Effective welding area | 400 mm x 300mm | |

| Oven chamber height | 100mm | |

| Temp. range | Max to 450°C | |

| Table warming speed rate | Max 2℃/S | |

| Cooling speed rate | Max 2℃/S | |

| Heating rate | Max to 120°C /min | |

| Cooling rate | 120℃/min (The cabin is equipped with integral cooling water circulation) | |

| Transverse temperature difference | ±1% | |

| The drawer bearing weight | 5kg | |

| Power | Max:21.5kw, Working power:8-10kw | |

| Heating table | Copper with special treatment | |

| Power supply | 380V, 50HZ/60HZ | |

| Electric current | max. 3 x20 A, 50-60 HZ | |

| Gas | Nitrogen system | |

| Formic acid gas | Formic acid reducing atmosphere (optional) | |

| Visual monitoring system | Observe the melting state of solder in the welding process in real time, and record, so as to facilitate the analysis of solder and material; (optional) | |

| Control Parameter | Control mode | Siemens PLC + Touch screen |

| Monitor window | With 1 monitor window | |

| Temp. Profile setting | Temp +Time (can set temp, time and temp warming ramp rate)(the most can set 150 process stages) | |

| Interface | COM | |

| Security System | Oven chamber temp. extra-high alarm, over degree of process warming alarm | |

| Cooling water pressure detection system, low pressure alarm, software prompt | ||

| Air pressure detection system, high and low pressure alarm, software prompt | ||

| The door is not in place for inspection and protection | ||

| Separate electrical components from water - cooled components | ||

| Cooling water pressure detection system, low pressure alarm, software prompt | ||

| One key to cut off part of the heating power | ||

Formic acid supply system

List of configuration:

| Item | Description | Specifications | Quantity | Remark |

| 1 | Main Machine | JB-V20 | 1set | |

| 2 | Software | V1.1 | 1set | Upgrade for free all time |

| 3 | Control System | JAGUAR standard | 1set | PLC(SIEMENS)+ IPC(Advantech)

|

| 4 | WatWater Cooling System | JAGUAR standard | 1set | Hardware equipment |

| 5 | Mechanical Vacuum Pump System | AVR-30 | 1set | |

| 6 | Nitrogen Control System | JAGUAR standard | 1set | Standard configure nitrogen control system |

| 7 | Vacuum Parts, Tool and Heating Tube | JAGUAR standard | 1set |

Heating Table: Special harden treatment cooper heating table

Features: `

1.Observation system: the cavity has a visual window to observe the welding process in real time

2.Heating system:applicable to IGBT modular,high power device, LED observation system, Chamber with visual window, can observe soldering process, Sintering and welding of encapsulated semiconductor devices, top output power is set according to different product requirements.

3.Up and bottom heating system, configure electric current regulator, can do high precision dynamic temperature control and ensure temp. uniformity of bearing platform

4.Vacuum system:machine configure DC high speed rotary vane vacuum pump, can rapid realize oven chamber’s vacuum environment to 0.1mbar, the highest vacuum degree to 0.1mbar

5.Cooling system:machine adopt water cooling system, to ensure rapid cooling under high temperature vacuum environment

6.Software:programmable warming control, can set the up down temp. profile according to process, each profile automatic generated, editable, modifiable and storable.

7.Control system:software modular design, process profile, vacuum extraction, atmosphere and cooling all can set independently, can combine the production process to achieve a key operation

8.Atmosphere system: machine realize no flux soldering, can recharge H2, N2/H2 mixed atmosphere, HCOOH, N2 reduce and protected air, to ensure no cavity in solder joint(H2, N2/H2 mixed atmosphere is optional)

9.Data record system: with uninterrupted real-time monitoring and data record system, software curve record temperature control curve save process parameters save equipment parameters record call

10.Multi-process atmosphere:N2,N2/H2,pure H2,HCOOH(N2 carrier gas),ArH2 plasma assisted process;(N2 and N2/H2 gas process optional)

11.Cold wall heating design, low heat capacity heating plate with optical coating, array infrared heating quartz lamp and N2 air cooling nozzle, built-in temperature measuring thermocouple, forming fast and accurate automatic temperature control capability

12.Heating plate layer bearing, single layer bearing 5 kg

13.Rapid cooling speed: separate water cooling and gas cooling devices are installed in the cavity to realize rapid cooling of the welded devices

14.Low void rate welding quality: ensure that after welding, the large area of the pad to achieve a void rate of less than 3%

15.It can meet the high temperature welding requirements of materials such as lead-free solder paste and high quality welding requirements of solder paste vacuum environment

16.Flux recycle system, under the condition of stable vacuum in the production process, complete flux recovery, reduce the contamination of products inside the equipment

17.Visual monitoring analysis system (optional) : first, vacuum welding field for product welding process for real-time recording, vacuum synchronous recording temperature and the temperature curve, automatically save the video file, independently, the melting point of solder and state were analyzed, and facilitate product process adjustment, shorten the research and development testing cycle, intuitive and convenient to find process adjustment