Shenzhen Eton Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

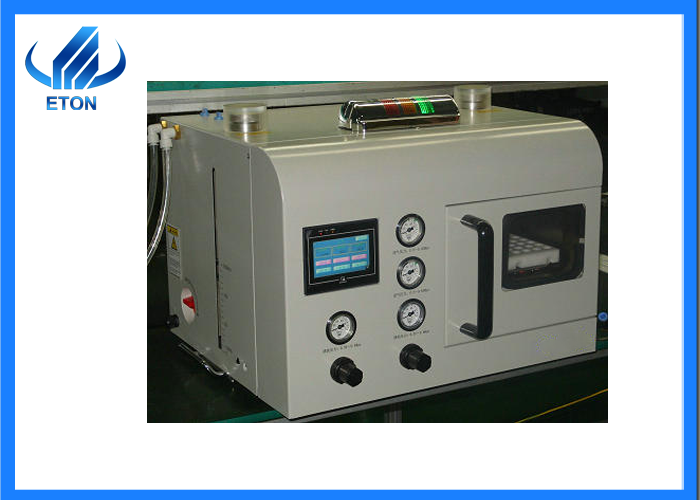

Automatic Nozzle Cleaner Automatic led lights assembly machine For SMT Line smt factory led light making machine led light production line in SMT factory layout

Product features of Automatic nozzle cleaner

Features:

1.No cleaning solution required

2.Low noise

3.High efficiency and energy saving

4.24 suction nozzles cleaned at a time

Principle and configuration features of cleaning machine:

1.The suction nozzle cleaning machine adopts a unique mechanical design. It uses fluid mechanics to break the water and produce a very small high-pressure water mist.

2.It forms a powerful kinetic energy jet on the suction nozzle at the sonic speed (v = 360m / s), forms a continuous energy field above the suction nozzle to be cleaned, and thoroughly smashes the dirt on the surface and inside (since the suction nozzle is placed independently, it will not damage the suction nozzle during the cleaning process). After cleaning, it will not damage the suction nozzle During the process, the cleaning solution (deionized water or distilled water) is automatically discharged directly.

3.High quality touch screen human-machine interface, PLC control;

4.The pneumatic part uses imported SMC pneumatic components from Japan, which ensures stable and efficient working efficiency;

5.The key parts of the whole machine are all made of 304 stainless steel imported from Japan, and the special parts are made of 316 stainless steel imported from Japan, so as to ensure that the whole machine will not rust due to the use of water, thus affecting the service life of the equipment and other safety hazards.

Technical parameter of automatic nozzle cleaner

| pressure | pressure | compressed air |

| Intake pressure setting | 0.5~0.55MPa | |

| Injection pressure setting | 0.35~0.38MPa | |

| Nozzle injection pressure | ≤0.4MPa | |

| Tube | Intake manifold | ¢12tube |

| Drain tank water pipe | ¢8tube | |

| Cleaning liquid | Cleaning liquid | Industrial deionized water |

| Liquid consumption | ≤300cc/h(5cc/min) | |

| Capacity of water storage tank | 1200cc | |

| Power Supply | Power Supply | AC220~240V |

| Plug | 3-Pin | |

| Consumption of electricity | ≤0.1Kw | |

| Environment | Working environment temperature | -5℃~ (But not frozen.) |

| Liquid temperature | 0℃~ (But not frozen.) | |

| Working environment humidity | 10~60%RH | |

| Environmental humidity of equipment | 10~60%RH | |

| dust | 0.1mg/m³(No conductive dust) | |

| Corrosive gas | Not allow | |

| Others | Outline size | 655(L) x 560(W) x 475(H) |

| Weight | (Including cleaning fluid 2000cc) |

Automatic nozzle cleaner machine SMT machine pictures

Exhibitions

Our company participates in many exhibitions at home and abroad

every year,

in China, including large-scale exhibitions held in Shenzhen,

Guangzhou, Chongqing, Shanghai and other places.

Foreign exhibitions include exhibitions in more than 20 countries

including Mumbai, Delhi, Egypt, Turkey, and Vietnam.

For SMT factory setup,we can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve many question about SMT

Five star Services

Pre-sale, on-sale and after sale,Technical support; We have

professional service team, Rich experience, ensure to solution the

customer’s questions. Always provide best support to you!

1)Pre-sale:

Provide equipment, such as pick and place machine, stencil printer,

reflow oven, conveyor,etc.

SMT whole line solution, based on customer’s factory layout,

requirement, product, etc.

2)On-sale

Real-time follow-up of the production situation of the customer's

machine.

Inform the customer of the production progress with video or photos

3)After sale

On-site Free installation

One-year Warranty factory service

Two regular visits customer one year

Free technical training

Software:Independent research and development by ETON, free upgrade

whole lifetime, saving costs.

4)Technical support

Free technical training of operating and maintenance

7*24 hours technical online support.

Local engineer in India(Delhi, Mumbai and Daman), Turkey, Egypt

Contact me:

Ethel

whatsapp/wechat/TEL:+8613824337025

email: ethel@eton-mounter.com