Jiangsu Sinocoredrill Exploration Equipment Co., Ltd |

|

Verified Suppliers

|

|

Polycrystalline Diamond Compact PDC Core Drill Bits for High Speed Drilling

Description of Goods

Theory

PDC(TSP) core bits are similar to surface-set diamond bits in that they are set with a single layer of cutters mounted on the face of the bit in a pre-determined pattern. Instead of natural drill diamond however, the cutting media used on geotechnical bits are synthetic polycrystalline diamond elements. These elements are composed of micron-sized particles of synthetic diamond that have been formed into various geometric shapes.

Like surface-set diamond bits, geotechnical bit crowns consist of a tough wear resistant matrix body that as a minimum includes natural diamond gauge protection setting. In most cases, the gauge protection setting is augmented with seismic grade tungsten-carbide pads and/or polycrystalline diamond elements.

Shear is the mechanism by which geotechnical bits cut the formation being drilled. In softer formations, these bits are capable of very high rates of penetration when compared to surface-set diamond bits due largely to their high degree of cutter exposure.

TSP Core Bits are ideal for geotechnical drilling applications. They are suited for soft to medium hard formations, such as clay, shale, sandstone, limestone, marble, basalt, etc

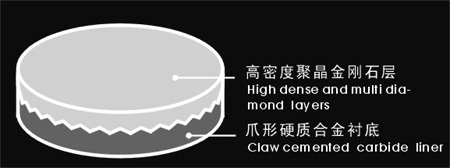

Introduction of PDC (Polycrystalline Diamond Compact)

PDC is made of diamond micro-powder and hard alloy substrate under high temperature and high pressure. It possess of high wear resistance like diamond, at the same time the impact resistance like hard alloy and that’s made it the best material as a drill bit cutter. Reinforced PDC has higher dense diamond powder, claw hard alloy substrate made the two layers solid as whole one. So, the reinforced PDC of supper wear resistance, longer service life and high efficiency.

Suitable for soft to medium mations(f=1-10), particularly suitable

for harder rock construction, not available in broken, fractured,

strong abrasive formations.

>The bit body are adopted advanced sintering technology, have

high strength and good gauge protection;

>High quality polycrystalline diamond compact (PDC) cutters as

the cutting teeth and advanced welding technology make the bits

have stable quality.

>The bits have strong stratum applicability, high drilling

efficiency and long life. The various performance are much better

than steel body PDC bits.

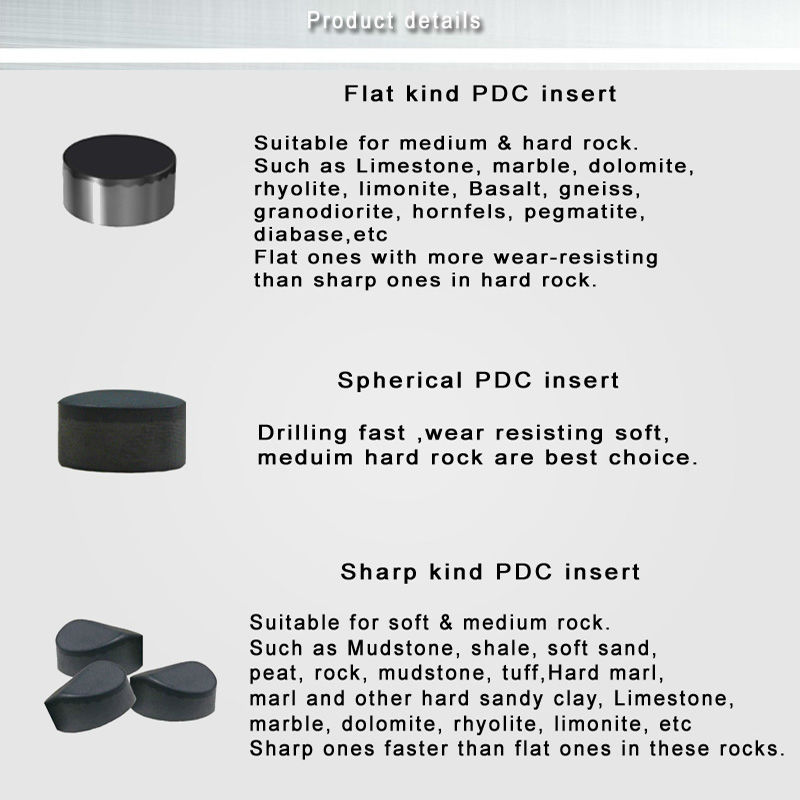

Product Details

Advantages of PDC

1. PDC cutters for high speed drilling;

2. All cutters are premium grade for extended bit life and durability;

3. Cutter layout is force balanced to drill a precise round hole and reduce bit whirl;

4. More total footage, faster ROP, reduced cost-per-foot;

5. Advanced geometric design for faster penetration;

6. Gauge pads have tungsten carbide inserts for maximum wear resistance;

Our Product Features

1) With feature of high working efficiency, smooth surface

2) Advanced technics and strict process control

4) Long lifespan and stable performance

5) Competitive price and superior quality

6) Excellent service

Advantages

1. Many years of experience combined with recent improvements in

technology and manufacturing concepts have resulted in greatly

improved drilling performance of impregnated PQ HQ NQ BQ diamond

core bits.

2. High quality synthetic diamond powders are distributed in the

depth of impregnated diamond core bit's matrix series. The matrix

layer of the crown contains a uniform distribution of these

crystals that are embedded in a powdered metal bond.

3. The matrix of our impregnated diamond core bits is designed to

expose new diamonds to the bits' cutting face as wear occurs. Fast

penetration rate is maintained as a result of this action.

4. Our impregnated diamond core bits are manufactured to give

optimum penetration rates and bit life, which is required to keep

the cost of diamond drilling to a minimum.

Delivery

Warranty and Service

We always concerned about our clients and provides them with warranty and service support.

The factory ensures equipment warranty for the major assemblies and units efficient for 12 months. The clients are supplied with all needed spare parts, tooling and auxiliary facilities.

The authorized dealers possess service centers to execute product warranty liabilities, after-sales service and equipment repair. The clients’ staff is also provided with theoretical and practical company instructions and consultations on all matters concerning execution of work and equipment operation.

Q: What's your delivery time?

A: Commonly need 7 working days to produce. Within 3 days if in stock.

Q: What methods of payment are accepted?

A: We agree T/T, L/C, West Union.

A: Based on order quantity. We can send it to you by Express, by Air, by Sea, and by Train. Or send the goods to your Chinese agent.

Q: How to control the quality?

A: We check & test every core drill bit before shipment.

Q: Do you agree samle order?

A: Yes, we welcome your sample order for testing our quality.

Q: Can we select the color of the drill bit?

A: Yes, we have standard rock hardness select index to choose core drill bit matrix hardness. If you need, we can make the core drill bit color based on your requirement.

Q: Do you have after-sale service and warranty service?

A: Any quality or quantity problem once confirmed, we will compensate you during our warranty period. Any question or problem we will reply you within 24 hours.

Q: Can I trust your company?

A: Our company has been certified by Chinese government, and verified by ISO-9001, just order from us!

Thank you for your support and we look forward to your inquiry!