Simplewell technology Co., LTD |

|

Vehicle VOC test chamber

Automotive VOC test, Automotive industry VOC testing, Vehicle VOC test chamber

Volatile organic compounds (VOC) can have an adverse reaction on technical products, components, humans, and the environment. Test your products under the right conditions. Browse our available VOC Test Chamber Solutions designed to ensure the safety and integrity of pieces, parts and products.

Application of VOC test chamber for vehicles

The chamber provides standard testing environment or simulates a real environment to test the pollutant emission rate and emission characteristics. Main environmental factors include temperature, relative humidity, illuminance, background concentration and air speed.

Testing

The operator first parks the vehicle in the test chamber and then sets all environmental parameters according to actual demands. Finally, he can get a sample and conduct odor analysis.

Manufacture Standards

* VOC Detection Method for Japanese JAMA Vehicle (Automotive air conditioning can be started.)

*National standard HJ/T400-2007 Determination Volatile Organic Compounds and carbonyl compounds in cabin of vehicles.

*GB/T 28370-2012 Detection Methods for Air Quality in the Coach

*VOC Test Methods for German VW PV 3938 Vehicle (Infrared Heating Method)

*ISO 12219-1:2012(E) Interior air in Road Vehicles-part 1: The Whole Vehicle Testing Environmental Chamber-specification and Method for the determination of volatile Organic Compounds inside the Vehicle.

Advantages of VOC emission test chamber

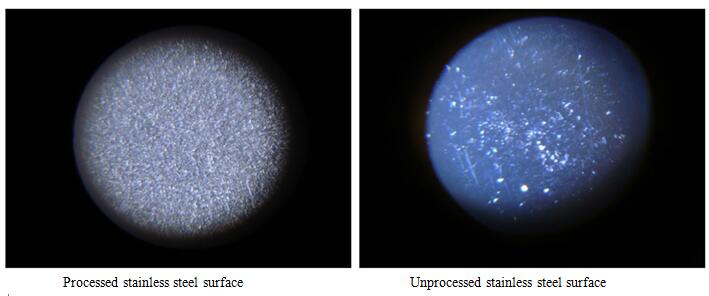

The coated stainless steel wall improves the adsorption capacity of test chamber of high-boiling-point materials and polar compounds. The chamber absorbs more than 80% of tetradecane and 4-phenyl-1-cyclohexene.

Technical parameter

| Model | VA-140 | |

| Temperature | Adjustable range | 20~ 30°C |

| Adjustment precision | ±0.5°C ( Fluctuation), ±1.0 °C ( Deviation) | |

| Measurement precision | ±0.1 °C | |

| Relative humidity | Adjustable range | 40~70%R.H. |

| Adjustment precision | ±5% R.H (Deviation) | |

| Measurement precision | ±1% R.H | |

| Ventilation rate | Adjustable range | 300~1200m3/h(Air change rate: 2.0-10times/hour) |

| Dimension of the inside of VOC compartments of the whole vehicle | 8000×5000×3500mm=140m ( depth×width×height) | |

| Dimension of the door of VOC compartments of the whole vehicle | 2800×3000mm ( height×width) | |

| Pressure inside VOC compartments of the whole vehicle | Compared to pressure outside the compartment, micro positive pressure | |

| Wind rate | ≤ 0.3m/s, with outlet at the smallpox mesh on the ceiling and return air at the bottom | |

| Maximum air processing volume of the filter air rate | m3 /h | |

| High-efficiency particle filter | Treatable maximum air volume: 1000 m3 /h | |

| Activated carbon filter/ chemical filter | Maximum wind processing volume: 1000 m3 /h Requirements on density of contaminants in air after treatment | |

| Background concentration of pollutants in the environmental chamber | 1. Benzene <0.010mg/ m3; 2. Toluene≤0.02 mg/ m3; 3. Xylene ≤0.02; 4. Ethylbenzene ≤0.02 mg/ m3 ; 5. Styrene≤0.020 mg/ m3; 6. Formaldehyde≤0.02 mg/ m3; 7. Acetaldehyde≤0.01 mg/ m3;8. 0.01 mg/ m3; | |

| Opening the door of the whole vehicle: due to great differences of materials of the vehicle, when opening the door of the whole vehicle, it should be guaranteed that voc of single component is smaller than 0.02 mg/ m3 or 10% of the limit; formaldehyde content is smaller than 0.02 mg/ m3; TVOC content is smaller than 0.2 mg/ m3 | ||

Three-dimensional graph

Main parts of VOC test chamber

Control system

The control system is manufactured with a LCD touchscreen (10.4inch) and a Mitsubishi controller, providing two operation languages (Chinese and English) remote control and touch input. Two operation modes are available, program mode and parameter setting mode.

Gallery

Cases

Through more than 20 years of hard work, we have establlished friendly relationship with customers both at home and abroad. Some of them are well-know companies and organation, like SGS, SONY, TUV AND FORD, etc.

For futher information pls contact with us:

| Item | Detail Information |

| Phone&Wechat ID&whatsapp | 0086 186 7605 0580 |

| Simplewell02@163.com;simplewell02@hotmail.com; | |

| Skype | 0086 186 7605 0580 |

| 1181717893 |