BOTOU SHIBO MACHINERY MANUFACTURING CO.,LTD |

|

Building Material IBR Roofing Sheet Making Machine 686 With Hydraulic Cutting

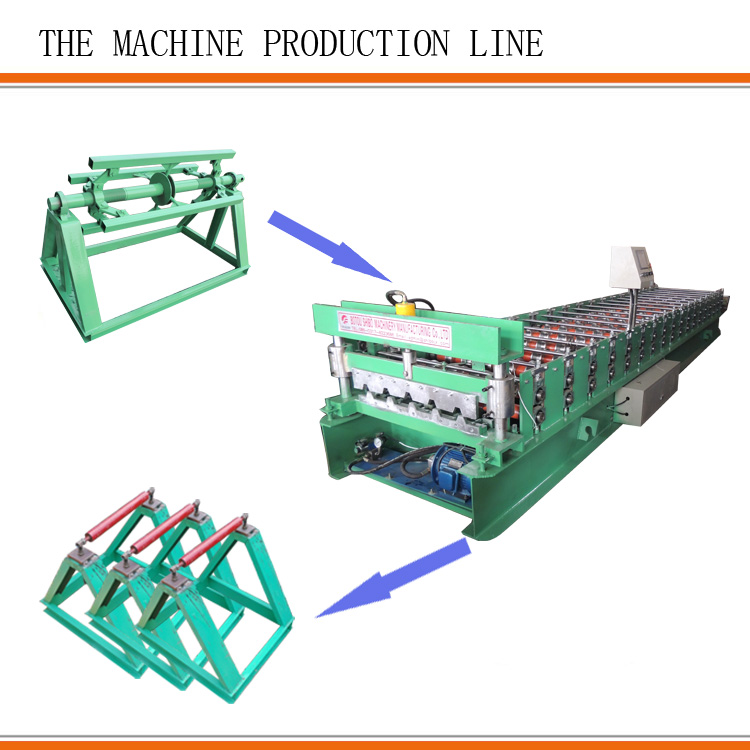

1. Usage and introduction of this production line

The complete Building Material IBR Roofing Sheet Making Machine 686 With Hydraulic Cutting line includes manual decoiler, main body of roll forming machine, hydraulic cutting system, PLC control system and discharge table. This machine is sold to South Africa, so this model roofing product is very popular in Africa.

2. Components of the roll forming production line

(1) Manual Decoiler

Un-powered, manual control

Max Feeding width: 1000mm,coil ID range 508mm±50mm

Bearing Capacity: Max. 5 Ton

Weight: 180kgs

(2) Main body of machine

| Feeding material | Color steel plate |

| Frame type | steel board welded |

| Width of the plate | 914 / 925mm |

| Thickness of the plate | 0.3-0.8mm |

| Dimensions | 7500mm*1500mm*1500mm |

| Diameter of the shaft | Φ75mm |

| Roller station | 18rows |

| Productivity | 8 - 12m/min |

Drive mode | A / C motor |

| Motor power to drive the machine | 5.5 + 4kw |

| Voltage | 380V 50Hz 3phase |

| Weight | 4300kgs |

| Material of the cutting head | Gr12 , heat treatment HRC58-60 |

| Machine frame | 350 H steel |

| Side board thickness | 16mm |

(3) Hydraulic Cutting device

The system includes: a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetism valves.

Power of the oil pump motor: 4kw Hydraulic oil :46#

(4) PLC Control System

It adopts industrial computer to control.

The target piece’s length is adjustable and digit of it can be adjusted.

Language screen:Chinese,English or Russian language .

(5) Discharge table

Un-powered, manual type

Function: collect the finished products

Dimension: 4000mm*1000mm*700mm

Weight: 80kgs

3. After-sales service

If the buyer need overseas debug, we can also send technician to your factory, the customer should undertake all related cost including the accommodation and round-trip ticket of technician: 100 USD/day . The buyer should make sure the safety of technician.

4. FAQ

Q1, How is this machine's service life?

A1, In the normal maintenance,the service life at least 7

years.

Q2, We bought your roll forming machine line, but we couldn't

install and debug it?

A2, Don't worry about that, when finished the machine, we will

send you the manual book which shows you how to use the machine; if

you still don't know, we can record a video to teach you how to

operate the machine.

Q3, How to maintenance?

A3, If using frequently,best coating lubricant on the chain and two

ends of the shaft every month, replace the hydraulic oil every 1-2

years.

5. The Building Material IBR Roofing Sheet Making Machine 686 With Hydraulic Cutting process flow chart and profile drawing.