BOTOU SHIBO MACHINERY MANUFACTURING CO.,LTD |

|

PPGI GI Steel Sheet Profile Roofing Panel IBR Cold Roll Forming Machine

1. Introduction of IBR 750 roll forming machine

(1) Manual Decoiler

-- One set manual type decoiler

-- Bearing capacity 5 tons

-- Bearing width of materail is 1000mm

(2) Main body of machine

Feeding material---------- Steel plate

Width of the plate--------- 1000mm

Thickness of the plate ----------- 0.3-0.8mm

Dimensions ------------ 7000mm*1500mm*1500mm

Diameter of the rollers ---------- Φ75mm

Rollers: ------------ 18rows

Productivity ------------ 8-10m/min

Total power ------------ 5.5+4kw

Voltage ---------- 380V 50Hz 3phase or at buyer's demand

Weight ---------- 5t

Material of the cutting head ----------- Gr12

Side board thickness -------- 16mm

(3) Hydraulic Cutting device

After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter machine to begin the cutting job.

(4) PLC Control System

The target piece’s length is adjustable and digit of it can be adjusted. You can devide which brand of PLC and inverter to use, Delta, Siemens or Achievement.

Computed mode has two Modes: automatic one and manual one. The system is easy to operate and use.

It contains programmer, transformer for the electronic machines and kits of every part.

Language screen:Chinese,English or Russian language .

(5) Discharge table

-- One set manual type decoiler

-- It is used to hold the roll forming panel products

-- The table length is 4000mm

2. The features of the IBR 750

The profile of this machine has seven high waves, top and bottom are opposite but with equal dimensions, it is stronger than usual profile, so it is popular in the area where has strong wind or heavy snow. It is usually used for big span warehouse or workshop.

3. After-sales service

Our machines have one year guarantee, within one year, if the machine parts has some problem, we will be in charge of the repairing or replace. Also we will deliver the customer some spare parts together with the machine when loading the machine.

4. Some questions you may care about

Q. How is this machine's service life?

A. In the normal maintenance,the service life at least 8 years.

Q. How to maintenance?

A. If using frequently,best coating lubricant on the chain and two

ends of the shaft every month, replace the hydraulic oil every 1-2

years.

Q. What can you do if the machine broken?

A. If the broken parts can't repair,we can free send the new parts

replace the broken parts to you except the solenoid valve,the

solenoid valve you must pay the express cost yourself.

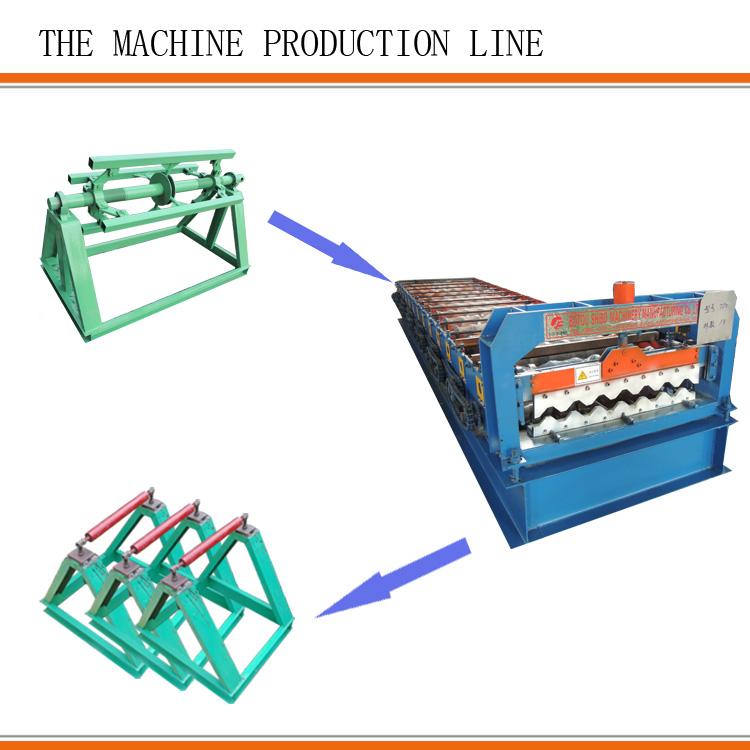

5. PPGI GI Steel Sheet Profile Roofing Panel IBR 750 Cold Roll Forming Machine process flow chart and profile drawing for your reference.