BOTOU SHIBO MACHINERY MANUFACTURING CO.,LTD |

|

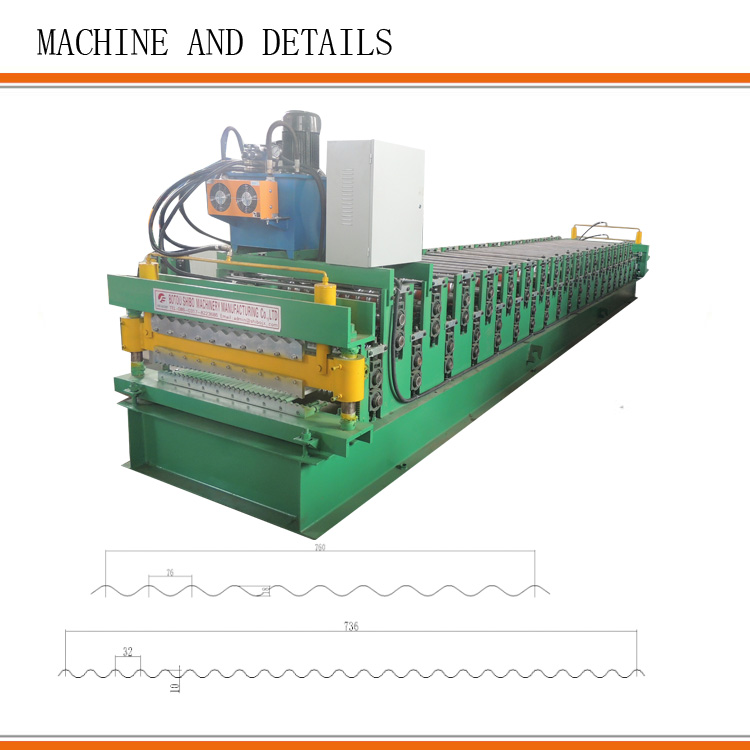

Double Deck Warehouse And Workshop Building Material Metal Roofing Roll Forming Machine 760-736

1. Usage and introduction of this production line

The complete Double Deck Warehouse And Workshop Building Material Metal Roofing Roll Forming Machine 760-736 includes manual decoiler, main body of roll forming machine, hydraulic cutting system, PLC control system and discharge table. The users can set order as per their requirement to produce the special pieces and length products. This machine line can work automatically by PLC control system. It is easy to operate and running stably.

2. Components of the roll forming production line

(1) Manual Decoiler 2 sets

Un-powered, manual control

Max Feeding width: 1000mm,coil ID range 508mm±50mm

Bearing Capacity: Max. 5 Ton

Weight: 180kgs

(2) Main body of machine

| Feeding material | steel plate |

| Frame type | steel board welded |

| Width of the plate | 914mm |

| Thickness of the plate | 0.2-0.6mm |

| Dimensions | 8600mm*1500mm*1500mm |

| Diameter of the shaft | Φ75mm |

| Roller station | 18rows , 20rows |

| Productivity | 8 -12m/min, 8 - 12m/min |

Drive mode | A / C motor |

| Motor power to drive the machine | 5.5 + 4 kw |

| All nut and bolt | 8.8 grade |

| Voltage | 380V 50Hz 3phase |

| Weight | 7900kgs |

| Material of the cutting head | Gr12 , heat treatment HRC58-60 |

| Machine frame | 350 H steel |

| Side board thickness | 20mm |

(3) Hydraulic Cutting device

It is controlled by gear wheel oil pump.

After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter machine to begin the cutting job.

The system includes: a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetism valves.

Power of the oil pump motor: 4kw Hydraulic oil :46#

(4) PLC Control System

It adopts industrial computer to control.

The target piece’s length is adjustable and digit of it can be adjusted.

Computed mode has two Modes: automatic one and manual one. The system is easy to operate and use.

It contains programmer, transformer for the electronic machines and kits of every part.

Language screen:Chinese,English or Russian language .

(5) Discharge table

Un-powered, manual type

Function: collect the finished products

Dimension: 4000mm*1000mm*700mm

Weight: 80kgs

3. After-sales service

(1) Once you paid the deposit, we will start the production as soon as possible. When the machine is finished, you can come to check the machine, we will arrange your accommodation and relative schedule. If you don't come, we can test the machine and send you test video. It's no problem.

(2) We provide a one year warranty and lifelong technical support, we can send our technicians to you to give you on-site training.

The training period would be for no more than one week with the customer paying for the visa, return ticket, food, accommodations and a daily wage of US100.

4. FAQ

Q1, If our country's voltage is different from yours, how to

solve that?

A1, The usual voltage is 380v,220v,415v. If yours are not one

of them, we will design the electric motor to suit your voltage.

Q2, We bought your roll forming machine line, but we couldn't

install and debug it?

A2, Don't worry about that, when finished the machine, we will

send you the manual book which shows you how to use the machine; if

you still don't know, we can record a video to teach you how to

operate the machine.

Q3, About the after service, if the machine has problem out of

guarantee?

A3, All the machines are one guaranteed, life maintenance. It

means if you order our machine, you will be our customer for

lifetime, you can ask us anytime about the machine issues.

5. The Double Deck Warehouse And Workshop Building Material Metal Roofing Roll Forming Machine 760-736 process flow chart and profile drawing.