Jiangyin Dingbo Technology Co., Ltd |

|

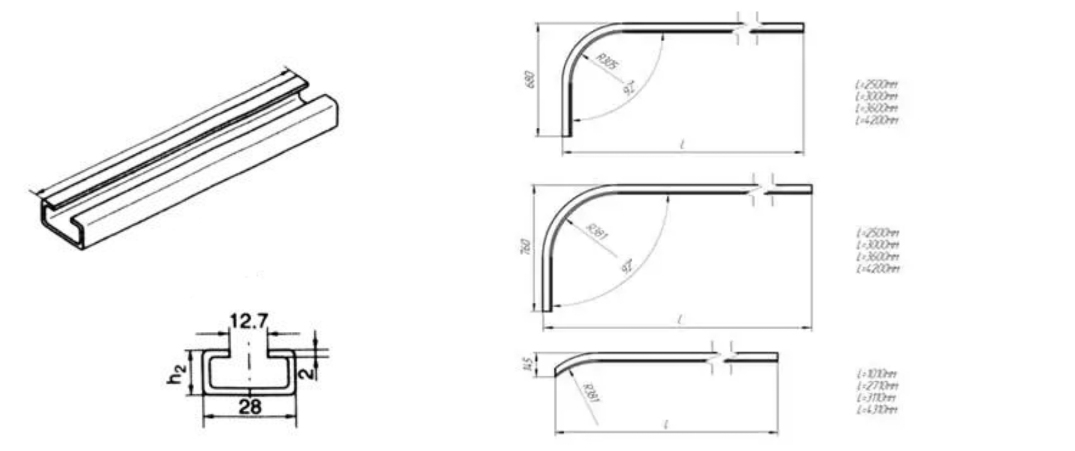

Cutting Automatically Shutter Guide Rail Forming Machine For Windows Track Rail Roll Forming Machine

Product Descriptions

Roller shutter door roll forming machine than traditional equipment with high efficiency, low energy consumption, and reduce environmental pollution, the steel structure also has a considerable breakthrough, bring more benefits to the market, with galvanized steel or different color steel or aluminum plate as raw material pressure equipment production line rolling shutter door, product color plate production volume gate brilliant color, do not fade, do not rust, widely used in store, workshop, warehouse, fire partition, strength is higher than the aluminum alloy door.

1. This machine contains our experiences in 30 years and many times

improvements by our engineers.

2. In our service, we support the equipment and profiles that

customers really need and including our most sincere recommends.

3. Our roll forming machines are driven by chain in hydraulic

system. Chain Drive System can save the power compare with other

system. That also means that customers do not need to pay the extra

power fee during production of steel panel.

This kind of machine used in simple house , steel plants and other

wall board production, speeds up to 15 m / min, greatly improve the

production efficiency .

Product Parameters

| Suitable material | Color steel sheet , galvanized steel sheet, |

| Main motor power | 5.5 KW with Cycloidal reducer |

| Thickness of material | 0.3mm~0.8mm |

| Hydraulic station power | 3KW(Lichao,Shanghai) |

| Hydraulic oil | 36#,40# |

| Diameter of principal axis | 50mm |

| Material expand width | 140-180mm |

| Electric tension | 380V 3phase 50HZ or as the customer's requirements |

| Material of roller | Cr12 steel quenched |

| Processing speed | 15-20m/min |

| Processing precision within | About 10m |

| Material of cutting blade | Cr12Mov with quenched treatment |

| Kind of drive | Gearbox |

| Roller station | 13 Roller Station |

Version to design

Working Flow

Main Components

| Component of roller shutter door roll forming machine | |||

| Name | Quantity | Units | |

| Decoiler | 1 | Set | |

| Main Machine | Feeding device | 1 | Set |

| Roll forming system | 1 | Set | |

| Cut Equipment | 1 | Set | |

| Hydraulic system | 1 | Set | |

| Electric control system | 1 | Set | |

| Supporter/Automatic Stacker | 1 | Set | |

Application Pictures

The shutter door is a door or window that consists of a number of

horizontal bars (or sometimes strip or mesh systems) that are

hinged together. On the door, the action may be maneuverable. It

provides weather protection and protects windows from vandalism and

burglary.

Rolling shutter doors have many applications, including vans,

garages, kitchens, schools, prisons and warehouse doors. In some

parts of the world, rolling shutters are subsidized by local

governments due to inherent safety concerns. In areas that are

frequently exposed to inclement weather, the rolling door is used

as an insulation method and the window can be protected from hail

damage.

FAQ

1. Q: What's the warranty period? (24hours online)

12 months warranty period, starting from the date of the successful

installation and commissioning of the equipment at the Buyer’s

Installation site. During which all parts damaged because of

quality problem will be changed for free.

2. Q: Do you have installation and commissioning service

A.If buyers come to our factory to inspect, the training to install

and operate is provided face to face. If not, manual and video is

provided to show how to install and operate.

B. If buyer need we will send technician to buyer site to do installation and commissioning and training.

C.installation and commissioning cost: One engineer will visit Buyer’s workshop for installing, commission and training. The buyer has to pay USD100/per day and visa fee, air tickets fee, accommodation and food, necessary communication, etc.

(Normally ,It takes about a week to install )

3. Q: What’s your after-sales service ?

We provide 24-hour online service for our customers.

And we are happy to give advice and also have skilled technicians available to maintain the machine overseas to customers’ workshop if needed.

4. Q: What's your delivery time ?

Normally we can finish production and testing within 45-70 days after receiving deposit. Some machines in stock, can be delivered at any time

5. Q: You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

6. Q: Do you provide customized machine?

Sure, we can design the machine according to the requirement and profile drawing you provide. Our engineers can offer the best professional solution to our worldwide clients.

7. Q: How to place order ?

Inquiry---confirm the profile drawings and technical specification and price----confirm the PI---arrange the deposit or L/C---start production-- do inspection--- Shipment

8.What are your terms of payment ?

First payment: 30 % by T/T, second payment: 70% by T/T, after the successful inspection at seller’s workshop, and before delivery.