Jiangyin Dingbo Technology Co., Ltd |

|

C/Z Purlin Roll Forming Machine

Product Descriptions

1.The purlins are now commonly used in the construction industry, with different shapes and sizes, the most commonly used are C purlin and Z purlin. Dingbo's purlin forming machine can produce both C and Z products on the same machine. It only takes 40 minutes to change between C and Z. In addition, the purlin machine can produce sizes between 100 and 300, easy to adjust, in just ten minutes.

2.What's important is that our purlins can be designed with a punching device and a punched hole in the punch that can be tightened during installation.

The operation is simple, the PLC control works automatically, and the machine ensures high-precision operation with a tolerance of ±1mm.

Version to design

Working Flow

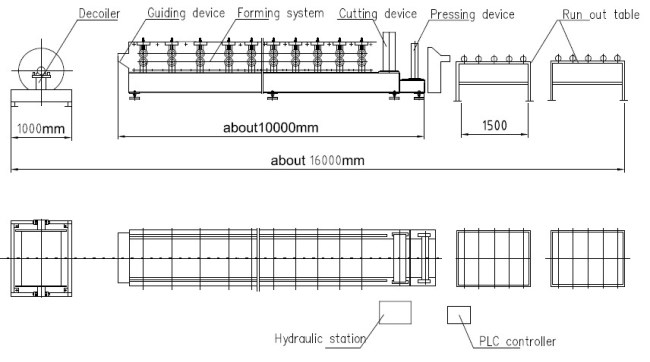

Hydraulic Decoiler -- Guiding device –Hydraulic Punching-- Roll-forming -- Cutting device -- Run out table

Product Parameters

1. The specification of the rolling production (mm): 80-300×L (see

appendix 1)

2. The speed of the roll-in: 12-15M/min

3. The number of the roller: 18

4. The material of the roller: use the excellent hammered steel

Cr15 to be quenched as a whole, then to process by numerical

control.

5. The material of the principal axis: use the excellent steel

No.45 to process.

6. The power of the principal electric motor: 18.5kw

7. Hydrodynamic station cut: 7.5kW

8. Drive-by-wire system: The whole machine uses the PLC industrial

computer to control by frequency conversion.

9. The size of the shape equipment: 10.3×1.5×1.2m

10. The gross weight of the equipment: 12.5T

Main Components

| No. | Name | Qty |

| 1 | Hydraulic decoiler | 1 |

| 2 | Guiding device | 1 |

| 3 | Hydraulic punching | 1 |

| 4 | Main roll forming machine | 1 |

| 5 | PLC Control box | 1 |

| 6 | Hydraulic station | 1 |

| 7 | Run out table | 2 |

Pictures