Wuxi Shuangti Stainless Steel Co., Ltd. |

|

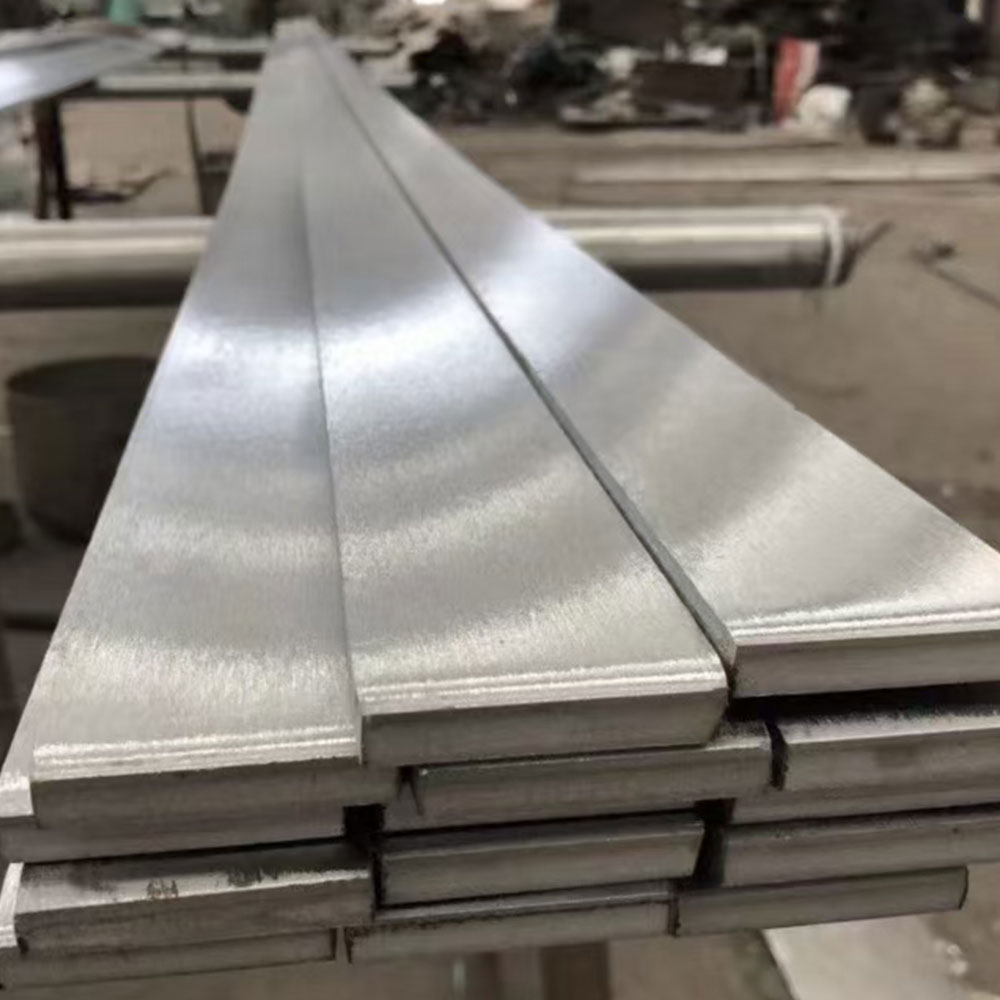

Ceramic Flat Trim Strip Floor Profile Stainless Steel Waterproof SS Flat Trim for edge corner trimming

Product description

| Product name | Stainless steel decorative profiles tile edge trim. |

| Surface treatment | 8K mirror,Hairline,Shiny, Matt,etching,Embossing, Anti-fingerprint,Or customized |

| Color | Silver, Golden,Rose Gold,Black Titanium,Red Copper, Champagne,Bronze,Sapphire,customized |

| Type | Stainless steel flat shape trim |

| Length | 2.44/3.05/4m per piece, or customized |

| Thickness | 0.4--3.0mm, or customize |

| Sample | Provide samples freely |

| Delivery time | 3--20days |

| Punching Hole Shape | Round, triangle, logo shape, or customized |

| Supply Ability | more than 20,0000 pieces monthly |

Stainless Steel Surface Treatments

1D—The surface has discontinuous particles, which is also called

matte. Processing technology: hot rolling + annealing shot peening

pickling + cold rolling + annealing pickling.

2D—Slightly shiny silver-white. Processing technology: hot rolling

+ annealing shot peening pickling + cold rolling + annealing

pickling.

2B—Silver white and better gloss and flatness than 2D surface.

Processing technology: hot rolling + annealing shot peening

pickling + cold rolling + annealing pickling + quenching and

tempering rolling.

BA—The surface gloss is excellent and has a high reflectivity, just

like the mirror surface. Processing technology: hot rolling +

annealing shot peening pickling + cold rolling + annealing pickling

+ surface polishing + quenched and tempered rolling.

No.3—has better gloss and rough surface. Processing technology:

Polishing and tempering rolling of 2D products or 2B with 100 ~ 120

abrasive materials.

No.4—has better gloss and fine lines on the surface. Processing

technology: Polishing and tempering rolling of 2D products or 2B

with 150 ~ 180 abrasive materials.

HL—Silver gray with hair streaks. Processing technology: Polish the

2D product or 2B product with a suitable size of abrasive material

to make the surface appear continuous grain.

MIRROR Machining —is in a mirror state. Processing technology: 2D

or 2B products are ground and polished to a mirror effect with a

suitable abrasive material.

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building construction |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Corresponding photo of stainless steel surface treatment

Stainless Steel Composition Contents Proportion Table

| 200 series | |||||||||||||

| Grade | chemical composition (%) | mechanic performances | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | N | Cu | Y.S(N/mm2) | T.S(N/mm2) | Elog(%) | HRB | |

| 201(1%nickel) | ≤0.15 | ≤1.00 | 8∽11 | ≤0.060 | ≤0.030 | 0.9∽1.5 | 15∽17 | ≤0.25 | 1.5∽2 | ≥310 | ≥655 | ≥35 | ≤105 |

| 202(4%nickel) | ≤0.15 | ≤1.00 | 6∽9 | ≤0.060 | ≤0.030 | 3.5∽5 | 15∽17 | ≤0.25 | 1.5∽2 | ≥260 | ≥620 | ≥40 | ≤100 |

| The specification of type 201&202 in conformity with Mill Standard | |||||||||||||

| 300 series | |||||||||||||

| Grade | chemical composition (%) | mechanic performances | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Y.S(N/mm2) | T.S(N/mm2) | Elog(%) | HRB | ||

| 304 | ≤0.08 | ≤0.75 | ≤2 | ≤0.045 | ≤0.030 | 8∽10 | 18∽20 | ≥205 | ≥520 | ≥40 | ≤90 | ||

| 301 | ≤0.15 | ≤1.00 | ≤2 | ≤0.045 | ≤0.030 | 6∽8 | 16∽18 | ≥205 | ≥515 | ≥40 | ≤95 | ||

| 316 | ≤0.08 | ≤1.00 | ≤2 | ≤0.045 | ≤0.030 | 10∽14 | 16∽18 | 2∽3 | ≥205 | ≥515 | ≥40 | ≤90 | |

| 316L | ≤0.03 | ≤1.00 | ≤2 | ≤0.045 | ≤0.030 | 12∽15 | 16∽18 | 2∽3 | ≥170 | ≥480 | ≥40 | ≤95 | |

| The specification of type 301,302,304,304L,309S,310S,316,316L,321,347 in conformity with ASTM & JIS criteria | |||||||||||||

| 400 series | |||||||||||||

| Grade | chemical composition (%) | mechanic performances | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Y.S(N/mm2) | T.S(N/mm2) | Elog(%) | HRB | ||

| 430 | ≤0.12 | ≤1.00 | ≤1 | ≤0.040 | ≤0.030 | 16∽18 | ≥450 | ≥205 | ≥22 | ≤88 | |||

| The specification of type 430,410,420J1.420J2 in conformity with ASTM & JIS criteria | |||||||||||||

| 630 series | |||||||||||||

| Grade | chemical composition (%) | mechanic performances | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Nb | Y.S(N/mm2) | T.S(N/mm2) | Elog(%) | HRB | |

| 630 | ≤0.07 | ≤1.00 | ≤1.00 | ≤0.035 | ≤0.030 | 6.50∽7.50 | 15.50∽17.50 | 0.15∽0.45 | ≥450 | ≥205 | ≥22 | ≤88 | |

| The specification of type 630 in conformity with ASTM & JIS standard | |||||||||||||

product photos

Wuxi T T Stainless Steel Co., Ltd. was incorporated in Nov.2011.Our company is engaged in stainless plate ,stainless sheet ,stainless tube ,stainless angle steel ,stainless channel beam ,stainless flat steel ,stainless round bar steel ,stainless section bars products .We concentrate not only on stainless steel products wholesale,warehouse ,but also on stainless steel logistics service all over the world .

Main Products

ⅠStainless Steel Plate.

Stainless steel plate surface is shining & polish,it has great fabricability with toughness & mechanic strength .It can anti-corrode acid or alkaline gas ,solution & other agents corrosion .

Stainless steel is a kind of alloyed steel ,it’s not inclined to rust .It has wide applications in many industries .It has many merits in anti-corrosion ,heat-resistance ,low temperature resistance and good performances of cold mechanic processing .

By the material divisions ,it can be divided into 201,304,304L,316L,310S,etc .

In conformity with executing criteria GB/T3280-2009 “Stainless Steel Cold Rolled Sheet & Ribbon”.

Universal specification dimension ;1000×2000,1220×2440,1500×3000,1500×6000,

1800×6000.It also can be tailored as per fabricated pieces .

Normally international cold rolled stainless steel sheet thickness is from 0.30-5.00 mm;

Hot rolled stainless steel plate thickness :3-16mm.Other irregular pieces thickness can be

Tailored as per client’s special requirements .

GB/T4237-2009 “hot rolled stainless steel plate & ribbon”.

ASTM A240/240M-10 “Pressure vessel and general purposeheat-refractory steel plate”

Π Stainless Steel Pattern Products

Many patterns available for options ,it’s suitable for stair footplates fabrication ,or laying plant anti-corrosion ,abrasion resistant floor

Ш Catch basin & gutter.

All kinds of dimension or thickness can be tailored as per customer’s special requirements .

Ⅳ Stainless steel angle steel ,channel beam ,flat steel,round bar steel ,tube,

Section bars .

Ⅴ. Stainless plate bending

Processing all kinds of irregular dimension pieces

Ⅵ. Stainless steel sheet circulating welding

Air duct production .

Ⅶ Processing capacity Leading 20000W large scale laser cutting machine .

Cutting pieces thickness 50mm by laser is so fast ,high efficient with full automation ,less effective on heat & local deformation .It will be helpful in improving accuracy .It can meet the needs of pieces processing diversities ,and can improve processing capacities ,and aid customers to save costs .

Ⅷ. Stainless steel sheet cutting & bending .

Cutting ,bending & circulating equipment can process length 9 M pieces .It can be

Utilized in all kinds of filling equipment ,air duct pipes .It can provide large

Scale , precise semi-products processing demands.

Ⅸ. Stainless steel surface processing .

Stainless steel mirror machining ,wire drawing ,plating procession .

Ⅹ. Aluminium alloyed products .

Ⅺ. Alloyed steel

Frequently asked Questions

FAQ

Q1. Can I have a sample order for your products ?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing ,8-10 working days for mass production.

Q3. Do you have any MOQ limit for stainless steel products ?

A: Low MOQ, 1pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Ship by DHL, UPS, FedEx or TNT. It takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5. How to proceed an order for stainless steel products ?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We are going to arrange the production.

Q6. Is it OK to print my logo on stainless products which we had ordered before from your company ?

A: Yes. Please inform us formally before our production.

Q7: Do you offer guarantee for the products?

A: Yes, we offer 1 years warranty to our products.

Q8: How to deal with the faulty?

A: Firstly, Our products are produced in strict quality control system and the defective rate will be less than 0.001%.

Secondly, during the guarantee period, we will send new stainless steel products with new order for small quantity. For defective batch products, we will recall them and resend them to you or we can discuss the solution including re-call according to real situation.

Q9. What main products are you ready to provide to us ?

1 stainless steel hot rolled plate

2. Stainless Steel cold rolled sheet

3. Stainless steel pipes or tubes .

4. Stainless Steel angles ,beam ,channels .

5. Stainless round bars

6. Stainless processing pieces .

7. Stainless laser cutting irregular pieces .

8. Aluminium plates

9. Alloyed steel

10. Nonferrous metals .

Q10 payment terms :

Normally we accept TT ,LC ,DP,west union ,paypal .