Shanghai Strong Metal Production Co., Ltd. |

|

Verified Suppliers

|

|

Wholesale Accessories Mud Flaps Black Splash Guards Sheet Metal Forming Parts

1 What does "sheet metal forming" mean?

Parts with complex shapes should be formalized. In the positive forming method, the need to support the

model, the shape of the support model should be consistent with the shape of the parts formed, the support

model and stamping mold has a great difference in the precision of the support model is not very high, and

the choice of materials is more flexible.

2 Technical Parameters

| Product name | Wholesale Accessories Mud Flaps Black Splash Guards Sheet Metal Forming Parts |

| Item | Bending Sheet Metal 90 Degrees Stainless Steel Tube Bending Sheet Metal Fabrication Sheet Metal Forming |

| Material | Stainless Steel, brass, copper, aluminium |

| Surface treatment | polishing, powder coating etc, brushing, degrease |

| Application | Industrial, building material, Auto, all fields, Machine parts |

| Tolerance | ±0.03mm, |

3 Product Details

Use: Electronic locker

Function: This is a part which used in the electronic locker and we

can easily to find out that it is a case of the

loker with ABS

Technology: plastic injection, burr remove

4 About Strong

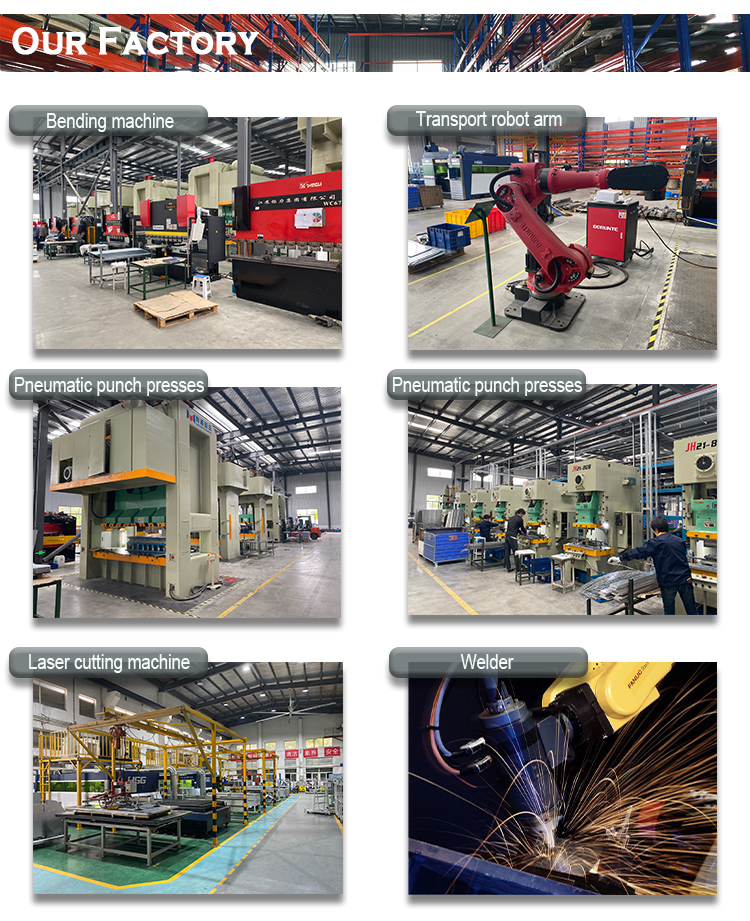

Strong focused on metal manufacturing and has comprehensive ability in mold self-design, metal

stamping, sheet metal, laser cutting, powder coating, welding, plastic injection, etc.

In 2021, the yearly turnover of Strong has exceeded 200 million yuan and we keep going to search

and offer better solutions to our customers and make more value to create a better world.

Strong has many advanced production equipments: 50+ punch press machines (highest 1000 ton),

20+plastic injection machines (highest 740ton), 20+ bending machines (highest 600 ton), 20+ automatic

welding arms, 50+ welding working tables, 8+ laser cutting machines, and a 400m powder coating line,

etc. In terms of the QC testing tool, We have CMM, a two-dimensional measuring instrument, hardness

tester, salty frog tester, etc.

5 FAQ

Q: What are your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance

before shipment.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is

15-20 days if the goods are not in stock,

it is according to quantity.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay

the cost of freight.

Q: Are you a trading company or manufacturer?

A: We are a manufactory.

If you have another question, pls feel free to contact us.