Riselaser Technology Co., Ltd |

|

Verified Suppliers

|

|

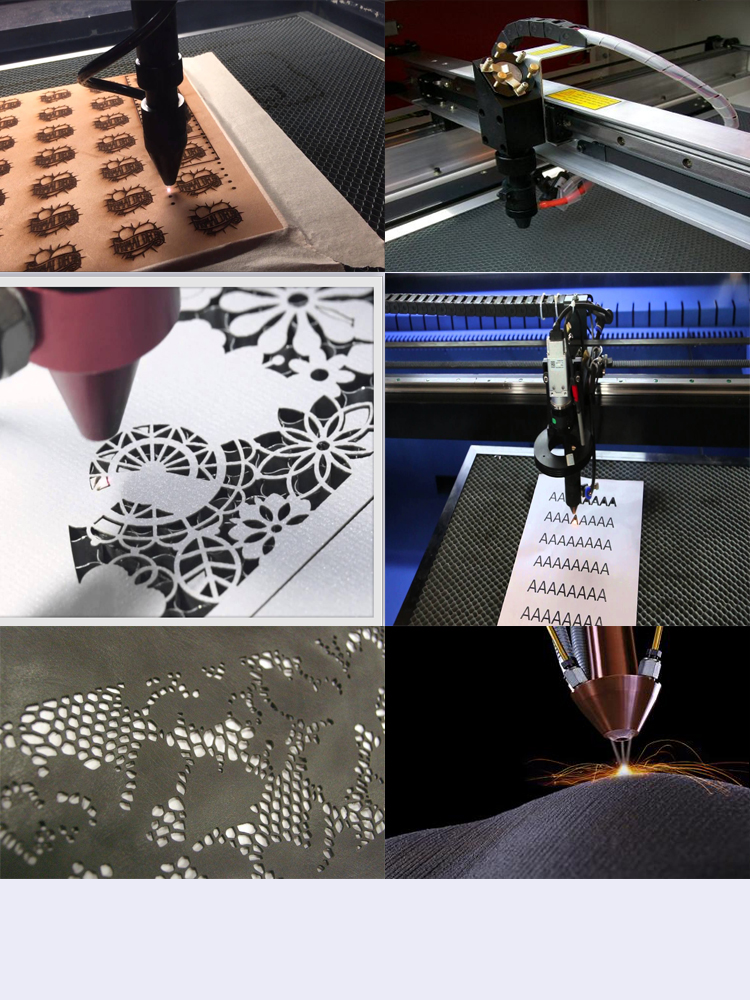

100W CO2 Fabric Laser Cutting Machine with Economical Price

Techical parameters of RL1390 100W co2 laser cutting engraving machine:

| 2 | Working area | 1300*900mm |

| 3 | Working table | Honey comb/ up and down/ knife (optional) |

| 4 | Laser power | 100W |

| 5 | Power Supply | 220V/50Hz/60Hz |

| 6 | Min line width | ≤0.15mm |

| 7 | Positon accuracy | 0.01mm |

| 8 | Repetition accuracy | 0.02mm |

| 9 | Smallest Character Engraving | Character2.0mm×2.0mm, English 1.0mm×1.0mm |

| 10 | Guide rail | Hiwin |

| 11 | Transmission method | Belt Transmission |

| 12 | Drive system | Leadshine driving system and stepper motor |

| 13 | Control software | Coreldraw, Photoshop, AutoCAD, etc |

| 14 | Working environment | 0-45℃ |

Main Characteristics:

1. USB port transfer flies, support offline work.

2. Newest laser work software, compatible with CoreIDraw and AutoCAD.

3. Imported focus len make engraving with high accuracy.

4. Laser tube power is 100w, fulfill engraving and cutting works.

5.Optional up and down worktable, convenient for thick material and cylinder materials work.

Main Features:

1 This trademark laser cutting machine is largely used for cutting all kinds of labels, trade mark, embroidery samples

2 The machine is adoption of leading technology in this industry, seek cutting edge according to different colors of brim or positioning characteristic point of trademark.Realize automatically positioning cutting and punching. Completely solve inevitable error caused by the manual position during the traditional laser cutting

process.

3 It signs that laser technology and automatic technology as well as man-made visual intellectual technology combined harmony, according to using of pickup positioning system. There is no question that it can do a good help for getting, continuous and positive productivity and improving product as well.

4 Time is profit the software design with the shortest cutting path key point of automatic positioning cutter. It can save working time about 10-20% in average that is to say increasing the profit about 10-20%, comparing with software without the shortest cutting path design.

5 The achievement of high-speed and continuous curve cutting function is based on powerful data treatment capacity of top DSP technology, special design of software in computer and the perfect makeup of precise machinery system. It will neither change for cutting line nor distorting for curve cutting, in the case of high-speed running.

Packing List:

| Machine parts | ||

| Name | Amount | Units |

| Water pump | 1 | sets |

| Air pump | 1 | sets |

| power line | 1 | pcs |

| Smoke pipe | 1 | pcs |

| Water pipe | 1 | pcs |

| Air pipe | 1 | pcs |

| Inner hexagon spanner | 6 | - |

| Tools bags | ||

| Name | Amount | Units |

| English manual book | 1 | - |

| Software CD | 1 | pcs |

| USB line | 1 | pcs |

| Silicone | 1 | pcs |

| Focus rular | 1 | pcs |

| Double sticky tape paper | 1 | pcs |

| Plugs and socket | 3 | pcs |

Applicable Materials:

Materials can be engraved:

acrylic, wood, cloth, leather, MDF, bamboo, rubber, glass, crystal,

granite, marble, tile, ceramic, paper, magic bean, painted metal,

etc.

Materials can be cut:

acrylic, wood, cloth, leather, MDF, plywood, bamboo, rubber,

asbestos rubber, paper, PVC, foam, EVA, plastic, etc.

| What material can the laser handle? | ||

| Material | Engrave | Cut |

| Acrylic | √ | √ |

| Glass | √ | × |

| Laminates | √ | √ |

| Leather | √ | √ |

| Paper | √ | √ |

| Plastics | √ | √ |

| Stone | √ | × |

| Textiles | √ | √ |

| Wood | √ | √ |

| Metal | x | × |

Service and warranty:

1. Before sale: we will try to know your requests about what work

you will do and help you

choose the most suitable machine specification & give you the

best solution.

2. During production: we will send photos of machines during

production. so customers

can know more details about the procession of making their

machines.

3. Before shipping: we will confirm the specification of order to

avoid the mistake and we

will test & adjust the machine until it has the best

performance.

4. After shipping: we will give you the tracking information of the

sea vessel so customers can know when it will arrive at your port

and make enough preparation.

5. After arrival: we will confirm with you if machine is in good

condition. and see if any spare parts were broken during sea

shipping then help to solve the insurance

6. About warranty: we offer 1 years warranty for whole machine and

six months warranty for laser tube.If any parts of our machine is

broken,we will replace it for free.(no human reason)