S&G Engineering Solution Lmt. |

|

Supermarket Upright Shelves Rack Roll Forming Machine With Cr12 Mould Steel Rollers

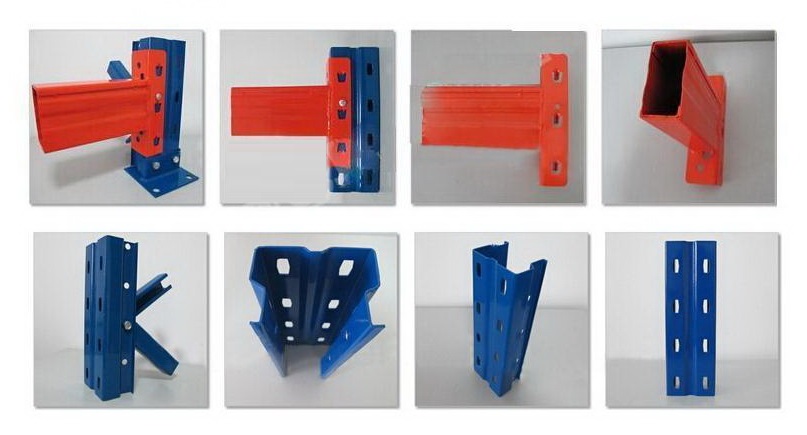

We are designing and manufacturing metal rollform equipments to make different storage racking panels, such as steel angle rack, pallet rack, strut channel, bracing rack, racking shelves and so on. All these machines adopt Mitsubishi PLC control system and separate automatic punching machine to produce the desired racking sheets with holes automatically.

Pallet rack is also called beam rack. It often come out to be heavy duty type and is the most conventional rack. Pallet rack can both store multi-veriety goods with small quantity and also unified goods with big quantity. Pallet rack is widely used in high warehouses.

1) Pallets can be located, accessed and moved individually.

2) Infinitely adjustable and offering a wide range of options and components.

3) Maximizes space use in any warehouse configuration while retaining optimum product accessibility.

4) Strength and rigidity prevents compression damage to goods.

5) Bottom level of pallets can be stored on the floor, lowering structure costs.

6) quality garantee 3 years

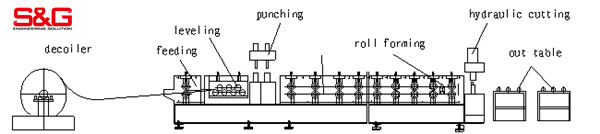

Production Line

Now we have two factories in Wuxi. The total production area is 35000 square meters, with a yearly production capacity of 30000 tons. We have more than 6 sets of rolling production lines, many sets of welding robots and 2 sets of full-automatic powder coating lines. We have been concentrating on racking products for more than 10 years. Our products are widely used in many industries, such as machinary electronics, automibile, pharmacy, electricity, garment and so on.

With many years of hard work, we have made our products not only popular in domestic market, but also in international market. We have won customer's praise from home and abroad.

We will keep providing the best products and the best service to customers. Let's share our aim o "quality first, Service foremost" and develop together, and create a prosperous future.

Main Components of Steel Angle Racking Panel Production line:

Working Flow

Decoiling --- leveling --- Servo feeding --- Punching Holes ---- Rollforming ----Cuting--- Finished Racks on Tables

| Main Accessories | ||

| 1 | Decoiler | 1 set |

| 2 | Auto Punching Machine | 1 Set |

| 3 | Main Rollforming Machine | 1 set |

| 4 | Straightening System | 1 set |

| 5 | Hydraulic Station | 1 set |

| 6 | Auto-Cutting system | 1 set |

| 7 | PLC Control System | 1 set |

| 8 | Run Out Table | 1 set |

| Technical Information of Supermarket Upright Shelve Rack Roll Former | ||

| 1 | Material width | As your regards |

| 2 | The effective width | As your regards |

| 3 | The thickness of Coil | 1.0-2.5mm or more |

| 4 | Application | Upright Shelves Racking Panels |

| 5 | The overall dimensions | 13 x 1 x 1.4 meters |

| 6 | Total weight | 12 Tons |

| 7 | Main Power | 15KW |

| 8 | Uncoiler | Manual Uncoiler |

| 9 | Inner diameter | 508-610mm |

| 10 | Outer diameter | 1200mm |

| 11 | Loading weight | 3 tons |

| 12 | Forming speed | around 10m/min |

| 13 | Forming steps | 25 stations or more |

| 14 | Bracket | welded with 36 # I-steel |

| 15 | Material of Shafts | 45# steel with rough finished and then refined finished |

| 16 | Diameter of the Roll | 80mm |

| 17 | Material of Rollers | high quality Cr12 mould steel |

| 18 | Processing Technology | quenching & tempering treatment |

| 19 | Material of Rack | complete welded structure of A3 steel plate 16mm thickness |

| 20 | Transmission | Transmitted by the chain-bracket/ Gearbox T180 |

| 21 | Material of Chain | 45#steel with heat treatment of HRC45-50° |

| 22 | Holders under chain for lubricant | By the machine |

| 23 | Material of cutting blade | Cr12 mould steel with quenching treatment 60-62 |

| 24 | Cutting system | Hydraulic Post-cutting |

| 25 | Voltage | 380V/50HZ/3phase |

Pre-sale Service

1. Send you invitation letter, If you wanna visit our factory and check the machines.

2. Good Quality Manufacturer competitive price Quick Response Reliable Service for you.

Selling Service

1. Short delivery time after deposit 30-40 days.

2. Email you the production schedule and make prompt delivery for you.

3. We will count the cheapest shipping cost and fastest forwarder for you and send documents promptly.

4. Always be here for your service 12 hours per day.

After-sale Service

1. We welcome all feedback about our products and prices and services from our customers.

2. Any questions, please contact with us freely by E-mail or Telephone.

Features of Racking Roll Forming Machine

1. Gearbox as the transmission method, to make sure it can give

enough power to handle thickness material meanwhile make sure the

machine working steady.

2. Higher speed, normally speaking the machine working speed could

reach 15meter per minute.

3. Pillar stand frame to make sure machine structure is strong and

beautiful.

4. Best brand elements like PLC, hydraulic system and others.

5. PLC control system, so you can control length, working speed and

accuracy easily.

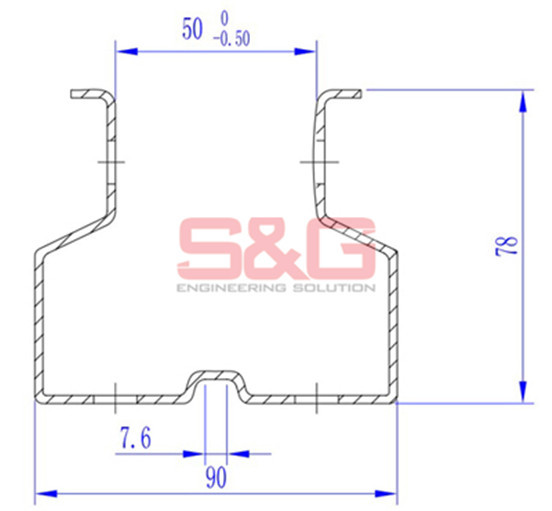

Profile Drawing:

Machine Picture: