S&G Engineering Solution Lmt. |

|

Customized Steel Angle Rack Roll Forming Machine 5 x 1 x 1.4 meters,Storage Rack Upright Roll Forming Machine

We are designing and manufacturing metal rollform equipments to make different storage racking panels, such as steel angle rack, pallet rack, strut channel, bracing rack, racking shelves and so on. All these machines adopt Mitsubishi PLC control system and separate automatic punching machine to produce the desired racking sheets with holes automatically.

Main Components of Steel Angle Racking Panel Production line:

- Uncoiler with two supporters

- Coil sheet direction adjusting equipment

- Main roll forming system

- Holes Punching Machine (optional)

- Post- cutting device

- Hydraulic station

- PLC control System

- Support tables

Technical Specifications of Steel Angle Rack Roll Former Equipment

Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable.

| No. | Main parameter of upright roll forming machine | |

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | As customer need |

| 3 | Thickness of the plate | 0.8-2.0mm |

| 4 | De-coiler | Manual one, can load 5 tons raw material |

| 5 | Rollers for forming | 20 rows |

| 6 | Diameter of the roller | Φ52mm |

| 7 | Rolling material | Carbon Steel 45# |

| 8 | Main motor power | 4kw |

| 9 | Productivity | 8-12m/min |

| 10 | Cutting method | Hydraulic mould cutting |

| 11 | Material of the cutting blade | Cr12 |

| 12 | Hydraulic cutting power | 3kw |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | Delta PLC control |

| 15 | Side panel of machine | 14mm |

| 16 | Main structure of the machine | 300 H steel |

| 17 | Weight | About 3.5T |

| 18 | Dimensions | 7.5*1.0*1.5m |

| 19 | Voltage | 380V 50Hz 3phases(changeable as needs) |

| 20 | Certificate | CE/ISO/TUV |

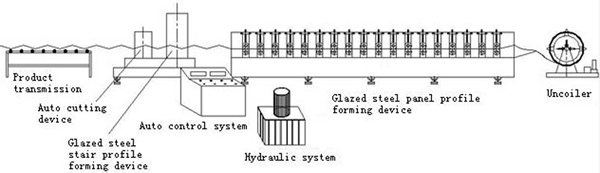

The processing progress of the shelf frame roll forming machine:

decoiler---roll forming part----hyrauic system--auto control system---auto cuttiing device--product table

Material Information for Machine Manufacturing:

- Roller: High grade No. 45 forged steel, plated with 0.05mm hard

chrome on the surface of rollers

- Active shaft material: High grade No. 45 carbon wrought steel of

diameter 75mm.

- Cutting blade: Cr12 mould steel with quenching treatment.

| Main Accessories | ||

| 1 | Decoiler | 1 set |

| 2 | Main Forming Machine | 1 set |

| 3 | Correction System | 1 set |

| 4 | Hydraulic Station | 1 set |

| 5 | Auto-Cutting system | 1 set |

| 6 | PLC Control System | 1 set |

| 7 | Run Out Table | 1 set |

1. we can produce the special machine,send your drawing to us,we can design for you.

2. if you buy our products,we also can help you to purchase the material,like color roll,the price is lower than you buy by yourself.

3. we provide a one year warranty and lifelong technical support, we can send our technicians to you to give you on-site training.

The training period would be for no more than one week with the customer paying for the visa, return ticket, food, accommodations and a daily wage of US50.

4. engineers available to service machinery overseas.

5. if you come to visit our factory,we can book the room for you,car pick up to send.

FAQ

A:- What service can you provide before order?

- About the pre-sale service. We provide you answers of all your questions on our machines, such as technical parameter, price, payment terms, ect. If you wanna visit our factory and check the machines, we also can send you invitation letter and give you our warmest welcome.

B:- Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

C:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

E:- Any other service?

- We can manufacture, design, installation and debug various roll forming machines including standard and customized machines.

It is free to assemble machine and train your works, but the buyer should pay for the round-trip airplane ticket, and arrange accommodation during that time.

F:- Can you accept OEM?

- We can accept OEM.

G:- Any certification:

- Yes, we have CE TUV BV certification.

Profile Drawing:

Machine Picture: