S&G Engineering Solution Lmt. |

|

Detailed Product Description

Auto decoiler is necessary for a roll forming machine with high

speed(more than 15m.min) because the manual uncoiler will drag the

speed. Manual uncoiler works manually, that is rotation with no

power and pulled by the roll forming machine and expansion with

manual forces. This electric uncoiler tenses and looses manually

but uncoils electriclly.

1. Coil Inner Diameter: 508mm

2. Coiler Outer Diameter: 1350mm(Max)

3. Loading Weight: 3T(Max)

4. Feeding Width: 20-350mm

5. Motor Power: 3KW

Machine Structure: High Quality Steel Plate Welded, Wall Panel Type

1. Forming speed: 0-20m/min, exclude cutting

2. Forming station: 13 stations

3. Diameter of the shaft:¢55mm

4. Roller material: Gcr15, HRC58~62

5. Shaft Material: 40cr

6. Motor Power: 5.5kw

7. Driven system: chain

8. 3 rollers straightening device, to make sure the product be

straight

1. Cutting Type: Hydraulic Cutting

2. Material Of Cutting Mold: Cr12mov HRC 60-62

3. Cutting Length And Quantity: Clients Can Set The Length and

Quantity on the PLC Touch Screen

4. Cutting Pressure: 12-16Mpa

5. Hydraulic Station Power: 4KW

6. Tolerance Of Cutting Length: +/-2mm

1. The worker input the length and quantity of the product through

touch screen, total 20 groups, the touch screen will show the

working status of the machine.

2. Computer Control System: Panasonic PLC

3. Encoder: Omron Brand

4. Frenquency Converter: Yaskawa

5. Touch Screen: MCSG

6. Controlled System Power: Overload Protection

7. Pressure Of Hydraulic Station: ≧12Mpa

8. Current: 380V Direct Current, 50Hz, 3 Phase

1. Type: Collect the product after cutting, Angle Steel Welded

2. Number of collection table: 2 piece

3. Size: About 2m*0.5m*1m(L*W*H)

Main Specifications

| Coil Material | Thickness | 0.22-0.35mm |

| Coil width | Custom-made | |

| Yield Strength | 100-260Mpa | |

| Material | Aluminum | |

| Decoiler / Uncoiler | Coil Width | Max. 350mm |

| I.D | 300mm | |

| O.D | Max. 560mm | |

| Roll Forming Machine | Forming stations | 37 Stations ( Depend on Profiles ) |

| Roller material | GCr15 steel, HRC58-62 | |

| Diameter of shaft | 40mm | |

| Shaft material | High grade 45# steel | |

| Drive type | Gear box with universal joint transmission system | |

| Forming speed | 15-30m/min | |

| Main power | 11KW | |

| Cutting | Cutting type | Pneumatic servo flying saw cutting |

| Cutting Tolerance | 10m+/-0.5mm | |

| Encoder | OMRON Brand | |

| Electrical control | PLC | Delta Brand or Custom-made |

| Inverter | Delta Brand or Custom-made | |

| Touch screen | Delta Brand or Custom-made | |

| Operation type | Touch screen & Button | |

| Runout Table | Table type | Simple nonpower type |

| Function | To support the finished panels |

A, Main technical parameters

| Working speed | 12M/min (without stop cutting time) |

| Forming roller station | according to the profile |

| Main motor power | according to the profile |

| Hydraulic power | according to the profile |

| Roller material | NO.45 steel with treatment, coated with chrome |

| Roller shaft material | NO.45 steel with treatment |

| Roller shaft diamete | according to the profile |

| Cutting type | hydraulic drive, cutting after forming |

| Shear material | Cr12 with quenching |

| PLC control system | Mitsubishi FX-IS series |

| Cut to length | 10m±2mm |

| Frequency | Dan Fuss |

| Control cabinet | xinjie OP320A |

B, Components

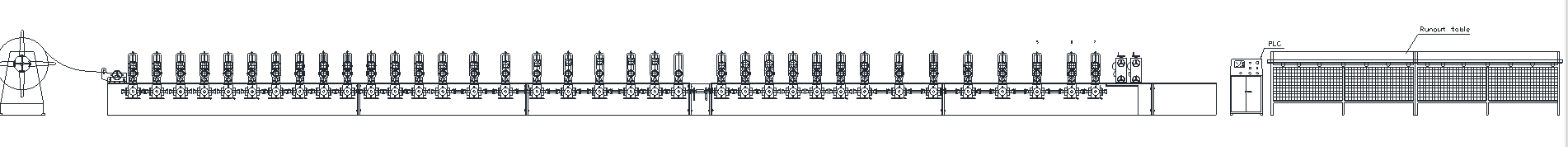

This machine is composed of 3T manual decoiler, transmission device, main roll forming machine (including guiding platform), back-seaming device, back-cutting device, PLC control system, hydraulic shear, and stacker.

C, flow chart

Decoil--guide feeding---roll forming---seaming---cut to length---run out table

D, Payment:

Pay 30% of total cost as deposit, the balance before delivery. L/C is acceptable. (Arrange the payment after the inspection of the machine is passed and before shipment.)

E, Warranty, Year warranty

During the warranty period, maintain and change the spare parts for the customers for free (except for the instrument damage caused by human factors or natural disasters.) And provide technical support for life-long.

Other descriptions,

1. Accompanied with working instructions and a CD. Please operate as required.

2. Machine only to be shipped after the inspection is passed.

3. CE certificated, guaranteed quality.

4. In a 40 feet container.

Main Components

| Main Roll Forming Machine | 1 Unit |

| PLC Computer Control Board | 1 Unit |

| Fast conveyor belt | 1 Unit |

| Decoiler / Uncoiler | 1 Unit |

| Cutting To Length | 1 Unit |

| Runout Table | 1 Unit |

Technical Process

Decoiling---foam--- Heat preservation---roll forming---automatic cutting---off---discharging

Roll forming Machine for production of insulated rolling shutter

door & window Insulated slats with Polyurethane foam-filled:

This insulated roller shutter door is strong one for large

structural openings, because of its thickness 1.2mm. It is solution

for the heavy rolling shutter door slate. This slat is roll formed

by two separated strips, the raw material can be colored steel or

GI steel, or aluminum material. This texture makes the rolling

shutter curtain less sensitive to surface damage, insulated rolling

shutters are associated with security.

Our roll forming machine is for production colored steel shutter

door & window slat with foam-filled, Our Roll-forming lines

complete with the tooling suitable to produce the foamed rolling

shutter profiles in different sizes,. inline foaming, and cutting

to length operations. Lines for high density or low density foamed

profiles.

Insulated Roller shutter slat with PU foam-filled:

Insulated Rolling shutters door now have been extremely popular in the whole world. The roll shutter business has become a multi-billion dollar industry. This style roller shutter door slat complies with the highest security in rolling fire doors, offshore rolling doors, storm doors, Rolling steel hurricane doors, insulated doors, Dock Doors, distribution outlets, food concession stands, hospitals, store fronts and oil-rig platforms. TAG: Insulated Roller Shutter slat, roll forming Machine, Insulated slat roll forming machine, Rolling shutters production, Rolling Shutter Roll Forming Machine

Custom insulated rolling shutter slat profiles are welcome! Pls

contact with us for the further details.

Competitive Advantage:

Product Images: