S&G Engineering Solution Lmt. |

|

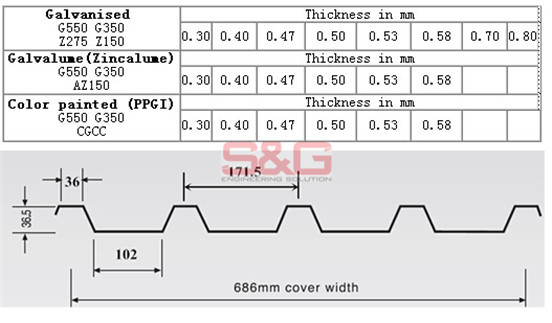

0.3 - 0.8mm Thickness Double Layer Roof Panel Roll Forming Machine For Roof Wall Cladding

What's the services ?

We provide the technical support for whole life. Meanwhile, if any parts go broken and not artificial damage, we will send you new ones for free. When need the technician to go abroad, we will arrange the technician. But the buyer should take all the cost, including Visa, Roundtrip ticket, suitable accommodation and pay the service fee to the technician with $100/days |

What is the Best Seller High Quality Double Layer Glazed Tile Mchine main parameters?

| No. | Main parameters of Best Seller High Quality Double Layer Glazed Tile Mchine | |

| 1 | Suitable to process | Colored Steel plate, galvanized board, Aluminum plate |

| 2 | Control system | PLC control |

| 3 | Productivity | Up layer: 0-3m/min, Down layer: 8-10m/min |

| 4 | Width of the raw material | 1000mm |

| 5 | Thickness of the plate | 0.3-1.0mm |

| 6 | Rollers | Up layer:15rows, Down layer:15 rows |

| 7 | Diameter of the rollers | Φ80mm |

| 8 | Rolling galvanization thickness | 0.05mm |

| 9 | Material of the cutting blade | Cr12 |

| 10 | Dimension | 8.7*1.5*1.5m |

| 11 | Weight | About 5T |

| 12 | Voltage | 380V 50Hz 3phases |

| 13 | Power | 4+4kw |

Details of Double Layer Roof Panel Roll Forming Machine

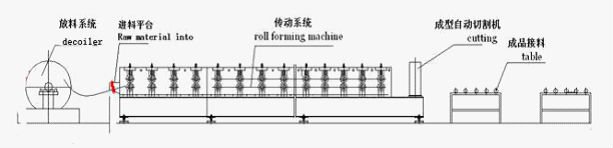

Work Flowing

Decoiling----> Sheet Guiding----> Coil Strip Leveling----> Roll Forming----> Cutting to length----> Output Table

Main Component

Application

Metal roof; steel roof; metal roof wall panel; steel roof wall panel; metal roofing sheet; steel roofing sheet; metal roof panel; steel roof panel; roof wall cladding; roof cladding; wall cladding

How to cooperate ?

| Step 1: Tell us your requirements |

| Step 2: Quoataion will be sent based on your requirement. Solution will be recommended to you as the alternative |

| Step 3: Negotiate and confrim each details for goods, trading terms and so on, get agreement and sign contract. |

| Step 4: Advanced payment and production |

| Step 5: Factory Examine Goods/ rectify and reform to meet the requirements of contract. |

| Step 6: Balance payment and shipping |

| Step 7: Handing Shipping files to help clients get goods from transporter in time. |

| Step 8: Clients get goods and go into warranty time. |

Q: Can you make the machine according to my design or proto type?

A: Yes. We have an experienced team for working out the most

suitable design and production plan for the machine that you are

going to book with us

Q: Are you a factory or trading company ?

A: We are a factory?

Q: Where is your factory located?

A: Our factory is located in YingKou City, LiaoNing Province, China. All our clients, from home or abroad, are warmly welcome to visit us !

Q: How do you guarantee the quality of the products?

A: Strict product quality, unqualified resolute don't factory.This is the tenet of our factory

Every one of our products have strict testing procedures, must be 100% quality assurance.

Q: How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for

checking the quality.

2.We can send the technicians to the buyer`s factory for the installation of the machine.

3.Good aftersales-service, its free of charge during the warranty period.

Profile Drawing:

Machine Picture: