ZHANGJIAGANG CITY PEONY MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

HFO Heavy Oil Treatment Diesel Oil Separator for Power Generating Station

We are one of the world's leading manufacturers of disc centrifuges, decanters, separation systems for land power station and container typer power plant. We focus on the necessary equipments on the power station, environmental protection, energy recycling, chemistry and etc. Now, there are over 150series of decanter centrifuges and disc separators used home and abroad.

Technical parameter:

| Discharging type | Manual discharging | |

| Max capacity | L/h | 14000(0# diesel oil) |

| Motor power | Kw | 11-15 |

| N.W. | kg | 730 |

| Volume of the slag cavity | L | 2 |

| Discharge type | Variable discharge | |

| Type of output | Centripetal pump | |

| Installation dimension | L × W × H (mm) | 1200x810x1225 |

Other oil capacity reference chart

| oil types | fuel oil | lubrication oil | |||||||||

| fuel oil | heavy fuel oil | SAE30,40 | detergence oil | steam turbine oil | |||||||

| kinematical viscosity(mm2/s) | 1.9-5.5 | 5.5-24 | 120 | 180 | 380 | 100-120 | 61.2-74.8 | ||||

| 40°C | 50°C | 40°C | 40°C | ||||||||

| density/(kg/m3)(20°C) | less than 900 | 900-991 | 880-900 | less than 900 | |||||||

separating temperature (°C) | normal temperature, 40-60best | 90-98 | 80-95 | ||||||||

recommended capcity (l/h) | 17500 | 14000 | 7700-8400 | 6300-7000 | 4900-5600 | 7000-8400 | 3500-4200 | 11200-11900 | |||

This system integrated in a standard 20 FT HQ and adopts IVS4 mode, that is, a set of auxiliary engine can satisfy the four sets of diesel generator unit at the same time.

Container integrated fuel oil supply &booster module , air compression module and fuel oil separation module. These three modules with their control system are relatively independent.

Container integrated HFO supply & booster module, diesel emergency supply and switch, Fuel oil booster, Light and Heavy oil automatically switching , air Compression and fuel oil separation module, and also equipped with relatively independent control system.

This module includes heavy oil transportation, filtration, heating, booster,viscosity and temperature control ,light diesel oil emergency booster and light-heavy oil switch. Meanwhile, it is aim to ensure the oil viscosity host fed and the pressure required. And starting diesel oil emergency module while the host fails. When the host starts or stops, it switches diesel for pipeline and equipment cleaning.

In this module, compressor, air dryer, air filter, air bottles, valve fittings and control system are included. Air compression module is mainly used for diesel engine starting up and also used in the fuel oil supply module for discharging of the self-cleaning recoil filter and in fuel oil separation module for pneumatic three-way valve.

In this module, fuel oil separator is the core of heavy oil separation module and will equip with corresponding pumps and valves according to the actual requirements of customers. The control system realizes intelligent fully automatic control by PLC display and Siemens program. This module is mainly used to separate the heavy fuel oil in heavy fuel oil setting tank, and pump to heavy oil daily service tank to supply for fuel oil booster module.

PS: In addition to the three integrated modules in the container, we will also involve in oil tank, heavy and light oil transportation, oil processing and so on.

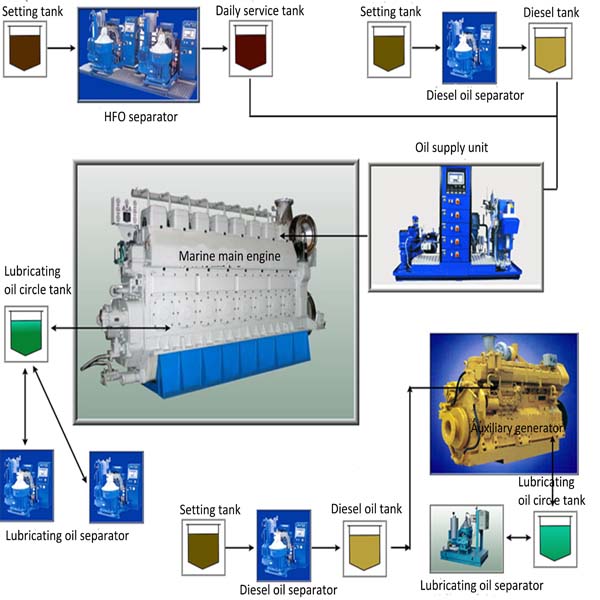

Relation application:

Advantage:

1. Moisture sensor(No-gravity ring) technology is adopted to ensure

the quality of the oil after separation.

2. Bowl with full hydraulic structure brings more thorough slage

discharge, more stable and reliable performance.

3. The new type seamless belt drive(No second tensioning required)

brings more reliable structure and more simplified mechanical

structure.

4. High rotating speed ensure the best separation effect.

5. Our separator is with low power consumption and light weight,

which is in accordance with the requirements of the national

industry.

Pictures:

14000l/H HFO Heavy Oil Diesel Oil Separator For Power Generating Station