ZHANGJIAGANG CITY PEONY MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

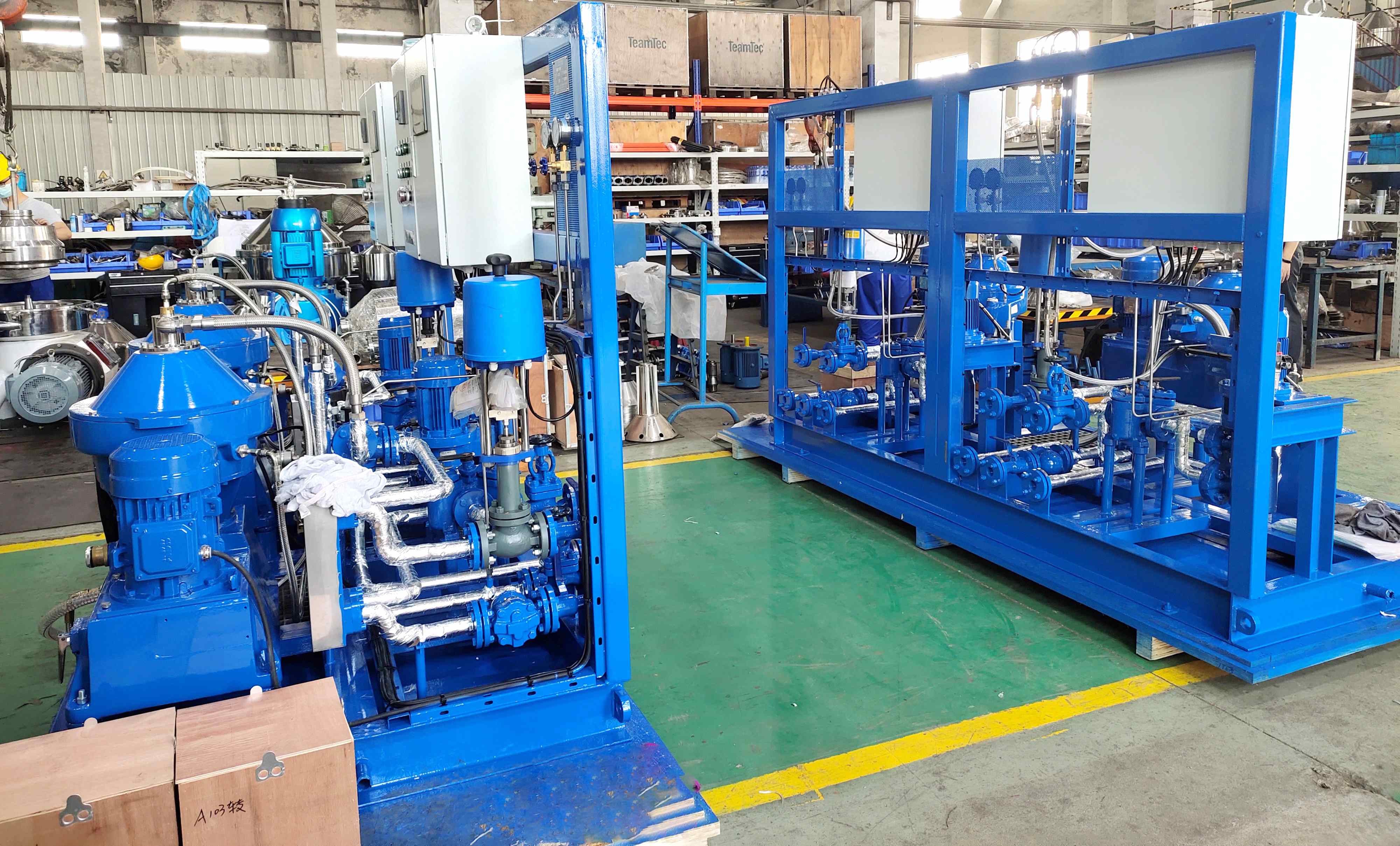

Automatic Continuous Air Compressor Centrifugal Oil Separator, Container Type

Product Overview

Model PDSD FO DO HFO oil treatment modular is widely used in the oil treatment for land power station,it will help to treat FO,LO,HFO,DO,with other equipments as oil tank,booster,oil suppling unit etc,we can recycle the waste oil till it can reach the industry using standard.

Brief introduction of fuel oil supply & booster module

This module includes heavy oil transportation, filtration, heating,

booster,viscosity and temperature

control ,light diesel oil emergency booster and light-heavy oil

switch. Meanwhile, it is aim to ensure the oil

viscosity host fed and the pressure required. And starting diesel

oil emergency module while the host fails.

When the host starts or stops, it switches diesel for pipeline and

equipment cleaning.

Brief introduction of air compression module

In this module, compressor, air dryer, air filter, air bottles,

valve fittings and control system are included.

Air compression module is mainly used for diesel engine starting up

and also used in the fuel oil supply

module for discharging of the self-cleaning recoil filter and in

fuel oil separation module for pneumatic

three-way valve.

Brief introduction of fuel oil separation module

In this module, fuel oil separator is the core of heavy oil

separation module and will equip with

corresponding pumps and valves according to the actual requirements

of customers. The control system

realizes intelligent fully automatic control by PLC display and

Siemens program. This module is mainly used to separate the heavy

fuel oil in heavy fuel oil setting tank, and pump to heavy oil

daily service tank to supply for fuel oil booster module.

PS: In addition to the three integrated modules in the container,

we will also involve in oil tank, heavy and

light oil transportation, oil processing and so on.

Detail Images

Condition for mineral oil separation and actual capacity(refer to the chart)

| Oil types | Fuel oil | Lubrication oil | Steam turbine oil | |||||

| Fuel oil | Heavy fuel oil | SAE30, 40 | Detergence oil | |||||

| Kinematical viscosity (mm²/s) | 1.9- 5.5 | 5.5- 24 | 120 | 180 | 380 | 100-120 | 61.2-74.8 | |

| 40℃ | 50℃ | 40℃ | 40℃ | |||||

Density (kg/m³)(20℃) | < 900 | 900-991 | 880-900 | < 900 | ||||

| Separating temperature (℃) | Normal temperature, 40-60 best | 90-98 | 80-95 | |||||

| Recommended capacity (L/h) | 17500 | 14000 | 7700~ 8400 | 6300~ 7000 | 4900~ 5600 | 7000~ 8400 | 3500~4200 | 11200~11900 |

| If you have special requirement, please connect with us. | ||||||||

Value Analysis

1.According to the requirements of each classification society, all modules are equipped with oil leak alarm and high temperature alarm.

2.Oil hydraulic,pneumatic control part adopts the Brand BURKERT (Germany).

3.Heater adopts brand SWEP (Germany).

4. Pressure control adopts Korean products or products

5. Screw pump is used instead of gear pump.

6. All equipped with automatic temperature control device (Made by the RTK production in Germany or made in China)

7. The main electrical components of standard electrical control box are produced by Schneider company while PLC is produced by Siemens or Mitsubishi.

8. The complete sets referred above are all Peony’s production of automatic Standard Controls and we certainly can modify the configuration list according to customers’ specified requirements.