ZHANGJIAGANG CITY PEONY MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

1VS1 1VS2 1VS3 1VS4 Power Plant Equipments Complete Fuel and Lube Treatment Modules

Production overview

A power station, also referred to as a generating station, power plant, powerhouse, or generating plant, is an industrial facility dedicated to the production of electric power. It typically houses one or more generators, which are rotating machines that convert mechanical power into electrical power. The generation of electricity is achieved through the interaction between a magnetic field and a conductor, resulting in the production of an electric current.

The choice of energy source used to drive the generators can vary significantly. Many power stations worldwide primarily rely on the combustion of fossil fuels, including coal, oil, and natural gas, to generate electricity. However, there is an increasing global trend towards using cleaner and more sustainable energy sources. Some power stations utilize nuclear reactions to generate electricity, while others are adopting renewable energy sources such as solar power, wind power, wave power, and hydroelectric power.

Our company specializes in supplying complete power plants worldwide that are based on heavy fuel oil (HFO) and/or diesel fuel. These power plants employ low or middle-speed generators (operating at less than 1000 RPM) and are designed for various applications, such as baseload, peak shaving, or standalone operation. Our range of power plants can cater to a wide range of power requirements, from a few megawatts to hundreds of megawatts. We provide HFO or dual fuel (fuel oil and crude oil) options to generate electric power at these stations.

Separation unit

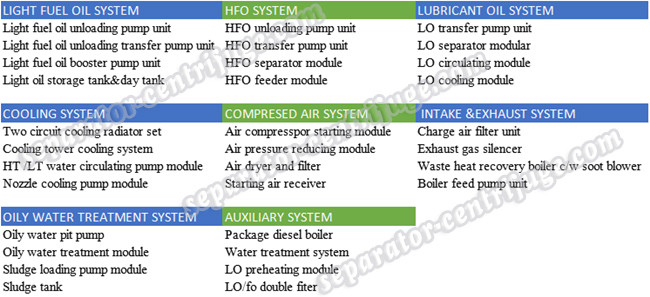

Supply scope

*Complete engineering package

*Produrement and project management

*Powerhouse including civil works,genset's foundation,steel structure,relevant ba;amce pf palnt equipment(air intakes,pumps and piping,exhaust stacks lo separation/filtration etc)

*Control room and electrical room according to the site design

*Control system,HMI and communication systems

*Cooling system for engines

*Optional heat recovery system

*Etc

Graphic model

Oil capacity table

| oil types | fuel oil | lubrication oil | |||||||||

| fuel oil | heavy fuel oil | SAE30,40 | detergence oil | steam turbine oil | |||||||

| kinematical viscosity(mm2/s) | 1.9-5.5 | 5.5-24 | 120 | 180 | 380 | 100-120 | 61.2-74.8 | ||||

| 40°C | 50°C | 40°C | 40°C | ||||||||

| density/(kg/m3)(20°C) | less than 900 | 900-991 | 880-900 | less than 900 | |||||||

separating temperature (°C) | normal temperature,40-60best | 90-98 | 80-95 | ||||||||

recommended capcity (l/h) | 17500 | 14000 | 7700-8400 | 6300-7000 | 4900-5600 | 7000-8400 | 3500-4200 | 11200-11900 | |||

Model PDSD14000 separator is mainly used to remove water and mechanical impurities from diesel oil, lubricating oil and other mineral oil in marine diesel engine unit and land-used diesel generator unit of power station so as to reduce wear of the diesel engine and other machine, and prolong engine life. The model is also used to separate two unsolvable liquids with different specific gravity or remove small amount of solid particle from liquid.

The machine adopts automatic control, and has the advantages of high efficiency, low oil consumption, convenient operation and economic maintenance cost.

The clear oil and dirty water are pumped out by centripetal pump, the sludge is discharged automatically and fully.

The machine is one kind of rotary machine with high speed. After accurate dynamic balancing, it can run for long time with low vibration, safety and security.

Reference list