Shanghai Xunhui Environment Technology Co., Ltd. |

|

Cast iron roots air blower for corrosive | toxic gases transfer Pressure 1000 mmAq Port DN300 Direct connect

Goods Description

The Roots Blower are improved by raising the intensity, it helps to prevent the center rotor and axis deviation from external influences. The rotor is used with the most advanced four-Shaft method in one time process, it can reduce man-made errors, enhance the precision of the lobe wheel and promote the blower efficiency. The air compartment and the side cover of the blower have a flange and groove rim, which can not only strengthen the blower's operational functions but also prevent eccentric phenomenal resulting from the fastening of the stud, which may shorten the life of the blower. Besides, noise and vibration reduction are the main emphasis in developing the new series of roots blower.

Features

Work priniciple of roots blower

There're two rotors in the compartment of the blower body, when the rotors rotate in opposite direction, they suck air in to balance the pressure created due to the volume V1 change on the inlet side. And the air in the volume V2 will be sent out through the discharge side and the high pressure will be created through the discharge.

There's no need lubrication between two rotors because there's gap between them for no touch moves, hence no friction. The blower runs well even at high spped and supply clean air, it also can be applied for vacuum purpose.

Specifications sheet

| Model | Frequency Hz | Capacity Qs(m³/min) Pressure(mmAq) Power La(Kw) | |||||||||||

| 1000mmAq | 2000mmAq | 3000mmAq | 4000mmAq | 5000mmAq | 6000mmAq | ||||||||

| Qs | La | Qs | La | Qs | La | Qs | La | Qs | La | Qs | La | ||

| THD-50 | 50 | 2.29 | 1.05 | 2.14 | 1.56 | 2 | 2.1 | 1.86 | 2.62 | 1.74 | 3.11 | 1.61 | 3.53 |

| 60 | 2.94 | 1.27 | 2.78 | 1.88 | 2.65 | 2.54 | 2.51 | 3.17 | 2.38 | 3.75 | 2.25 | 4.27 | |

| THD-65 | 50 | 4.03 | 1.7 | 3.76 | 2.5 | 3.55 | 3.3 | 3.34 | 4.2 | 3.23 | 5 | 3.03 | 5.8 |

| 60 | 5.17 | 2.1 | 4.89 | 3.1 | 4.68 | 4.1 | 4.47 | 5.1 | 4.26 | 6.1 | 4.16 | 7.1 | |

| THD-80 | 50 | 7.07 | 2.2 | 6.65 | 3.6 | 6.28 | 5 | 5.96 | 6.3 | 5.66 | 7.6 | 5.41 | 9 |

| 60 | 7.96 | 2.5 | 7.54 | 4 | 7.17 | 5.5 | 6.85 | 6.9 | 6.55 | 8.4 | 6.3 | 9.9 | |

| THD-100 | 50 | 10.5 | 3.4 | 9.96 | 5.2 | 9.51 | 7 | 9.14 | 9 | 8.82 | 10.8 | 8.57 | 12.7 |

| 60 | 11.8 | 3.7 | 11.2 | 5.7 | 10.8 | 7.8 | 10.4 | 9.9 | 10.1 | 12 | 9.82 | 14.1 | |

| THD-125 | 50 | 17.7 | 5 | 16.9 | 8.5 | 16.2 | 11.8 | 15.6 | 15.2 | 15.2 | 18.7 | 14.7 | 22.1 |

| 60 | 19.8 | 5.5 | 19 | 9.3 | 18.3 | 13 | 17.7 | 16.8 | 17.3 | 20.6 | 16.8 | 24.4 | |

| TH-125A | 50 | 22.5 | 6.3 | 21.6 | 10.6 | 20.9 | 14.8 | 20.2 | 19.4 | 19.6 | 23.4 | 19.1 | 27.7 |

| 60 | 25.2 | 7 | 24.2 | 11.7 | 23.5 | 16.4 | 22.8 | 21.4 | 22.3 | 25.9 | 21.8 | 30.6 | |

| TH-150 | 50 | 26.9 | 7.4 | 25.8 | 12.5 | 24.9 | 17.6 | 24.2 | 22.7 | 23.6 | 27.9 | 23 | 33 |

| 60 | 30 | 8.1 | 28.9 | 13.8 | 28.1 | 19.4 | 27.4 | 25.1 | 26.7 | 30.7 | 26.1 | 36.4 | |

Model selection

1. The air volume shown in above performance form, it's the suction

volume under standard suction condition (Temp. 20 ℃, absolute

pressure 1.0332 kg/c㎡, relative humidity 65%).

2. The convert formula between normal (for example: 0 ℃, 1.0332 kg/c㎡, ABS) and standard condition:

Qs=Qn * (yn/ys), y=0.465 * (P-0.378 ᵩ * Ps) / (273+t)

ᵩ=humidity (%) P=Pressure (mmHg)

Qn: air flow under normal condition N m³/min

Qs: air flow under standard condition (indicated in above performance table m³/min)

Y: air ration weight (kg/m³)

Ps: water vapor saturation pressure of the temperature (mmHg)

T: absolute temperature (273+t) ℃

3. Vice versa, an air flow under discharge condition can be converted to an air flow under standard condition:

Qs=Qd * (1.0332+Pd) * (273 +Ts) / (1.032*(273+Td))

Qd: air flow under discharge condition, m³/min

Ts: suction temperature

Td: discharge temperature

Pd: discharge pressure, kgf/㎡

4. Select blower type, diameter, rpm and shaft power based on performance table as required the air flow and discharge pressure.

5. Smaller size for economic view, and larger size for lower noise level & stabler performance for a long view.

Applications:

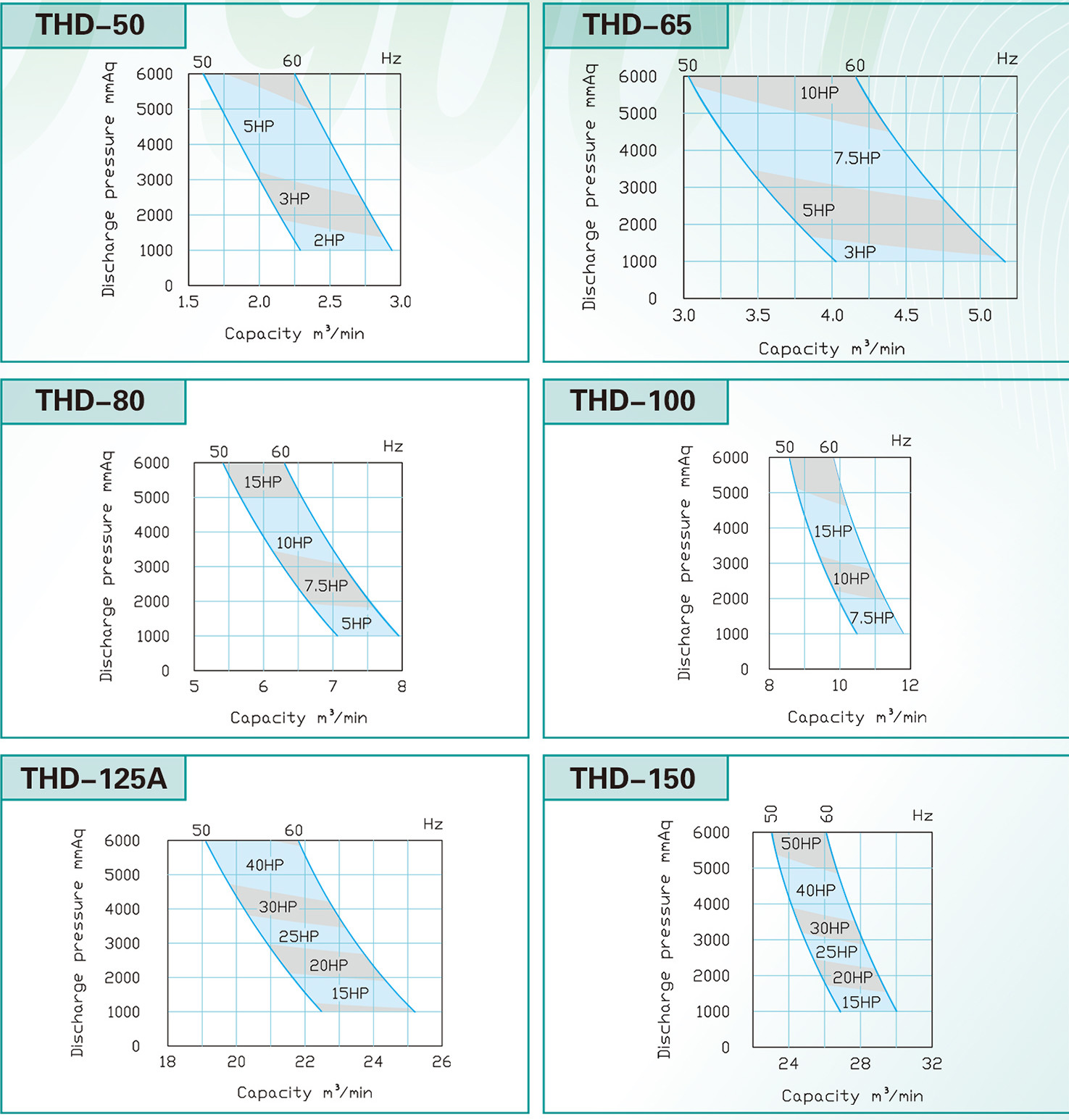

Performance curve

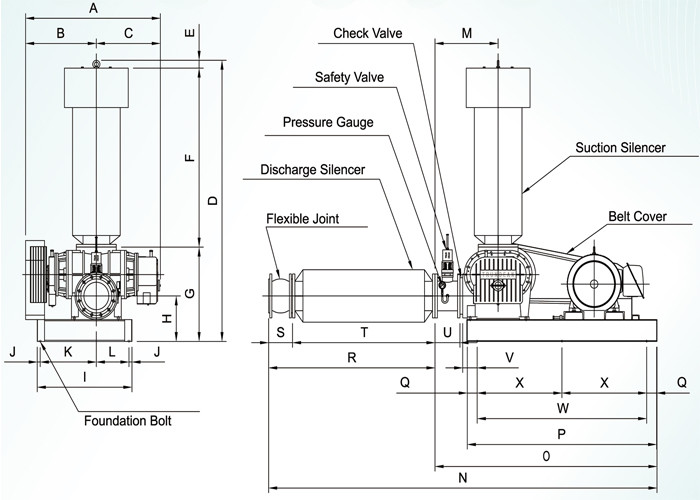

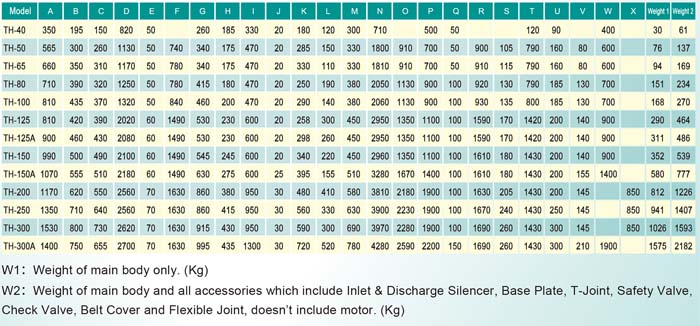

Product dimensions

Applications:

1. Air blowers / exhausters

2. Corrosive / Toxic gases

3. Non corrosive gases

4. Vacuum pumps

5. High pressure bossters

6. Vapour boosters

Competitive advantage

All our tri-lobe roots blower are built and checked annually following the strictest adhesion to ISO 9001 and CE quality standards, involving the use of our highly precise and regularly maintained CNC machinery. Scrupulous attention is paid to every detail, in a specialized field where technical errors should be kept to a bare minimum.