Shanghai Xunhui Environment Technology Co., Ltd. |

|

Volute screw press for oily sludge dehydrator and effluent treatment plant SS304 shaftless

Direct dewatering the oxidation ditch

The direct dewatering of low concentration sludge from the oxidation ditch (aeration tank) with volute removes odor by dewatering fresh aerobic sludge, reduces investment costs for thickening and storage equipment and operation cost. Additionally, phosphorous in waste activated sludge can be efficiently captured in the dewatered sludge cake, which reduces the load of returning phosphorous to the waste water treatment. Extrally, the condition of thesludge in the oxidation ditch (aeration tank ) is always stable, which further contributes to the stable dewatering process.

Application

Technical introduction

The volute is structured with a filter element that consists of two type rings: a fixed ring and a moving ring; and a screw that thrusts the filter element and transfers and pressurizes the sludge. The gaps between the rings and the screw pitch are designed to gradually get narrower towards the direction of sludge cake outlet and inner pressure of the filter element increases due to the volume compression effect, which thicknens and dewaters the sludge.

Features:

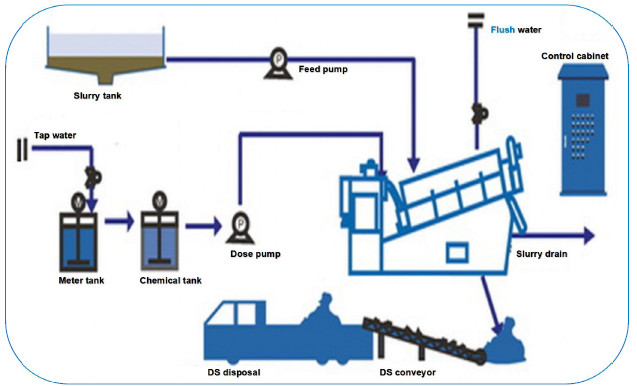

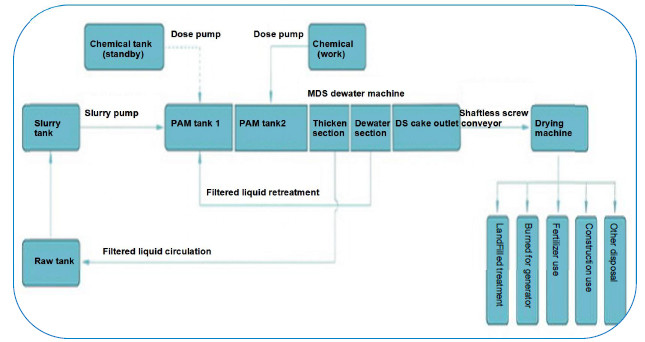

Sludge treatment process:

Flow diagram

Layout

Specification

| Model | DS treatment capacity(DS.KG/H) | Slurry Flow rate (M³/h) | ||||

| 10000mg/l | 20000mg/l | 25000mg/l | 50000mg/l | |||

| (low concentration) | (High concentration) | |||||

| KTDL131 | 5 | 10 | 0.5 | 0.5 | 0.4 | 0.2 |

| KTDL132 | 10 | 20 | 1 | 1 | 0.8 | 0.4 |

| KTDL251 | 15 | 30 | 1.5 | 1.5 | 1.2 | 0.6 |

| KTDL252 | 30 | 60 | 3 | 3 | 2.4 | 1.2 |

| KTDL301 | 30 | 60 | 3 | 3 | 2.4 | 1.2 |

| KTDL302 | 60 | 120 | 6 | 6 | 4.8 | 2.4 |

| KTDL303 | 90 | 180 | 9 | 9 | 7.2 | 3.6 |

| KTDL304 | 120 | 240 | 12 | 12 | 9.6 | 4.8 |

| KTDL351 | 50 | 100 | 5 | 5 | 4 | 2 |

| KTDL352 | 100 | 200 | 10 | 10 | 8 | 4 |

| KTDL353 | 150 | 300 | 15 | 15 | 12 | 6 |

| KTDL354 | 200 | 400 | 20 | 20 | 16 | 8 |

| KTDL401 | 80 | 160 | 8 | 8 | 6.4 | 3.2 |

| KTDL402 | 160 | 320 | 16 | 16 | 12.8 | 6.4 |

| KTDL403 | 240 | 480 | 24 | 24 | 19.2 | 9.6 |

| KTDL404 | 320 | 640 | 32 | 32 | 25.6 | 12.8 |

Advantages

Options

The Sludge Dewatering Press offers a completely operational, skid

mounted and self-contained system which can include:

• Screw Press

• PLC Controls

• Sludge Pumps

• Back Wash System

• Flocculation System

• Polymer Dosing Unit

• Sludge Cake Conveyor

Production line

Applications

| Municipal sewage | petro refining | leather making | printing and dyeing paper | paper & pulp | ||||||

| coalification dressing | biochemical | pharmacy | steel pickling | chemicals | ||||||

| sugar | food processing | food & beverage | mining | sludge treatment | ||||||

Competitive advantage

Multi-Disk Screw Press is a cutting edge sludge dewatering equipment with non-clogging design and low energy consumption, especially applicable for oily sludge.