Shanghai Schneider-Sunshine Mechanical Group Co.,Ltd. |

|

Adsorption Dryers Compressor

10RD Adsorption Compressed Air Dryer micro heated Compressed air

dryer

The blower intakes atmospheric air flow through the heater, then

through the desiccant media thereby regenerating it. With this

design, no dried compressed air is consumed for regeneration, which

maximizes the amount delivered to the air system. Blower heater Air

Dryer is usually suitable for large flow from 15 -510m3/min ,outlet

air pressure dew point is -40°C.

With an objective to fulfill the ever-evolving demands of our

clients, we are engaged in offering a wide assortment of Adsorption Compressed

Air Dryer.

Compressed Air Dryers are developed at our state-of-art

manufacturing unit that is the ideal energy saver for production

process. The compressed air that leaves the compressor is saturated

with moisture, dust and oil that are accountable for major

problems. They are known for reducing the amount of water vapor,

liquid vapor and other hydrocarbon vapor present in compressed air.

Dry and clean air can be obtained with the use of compressed air.

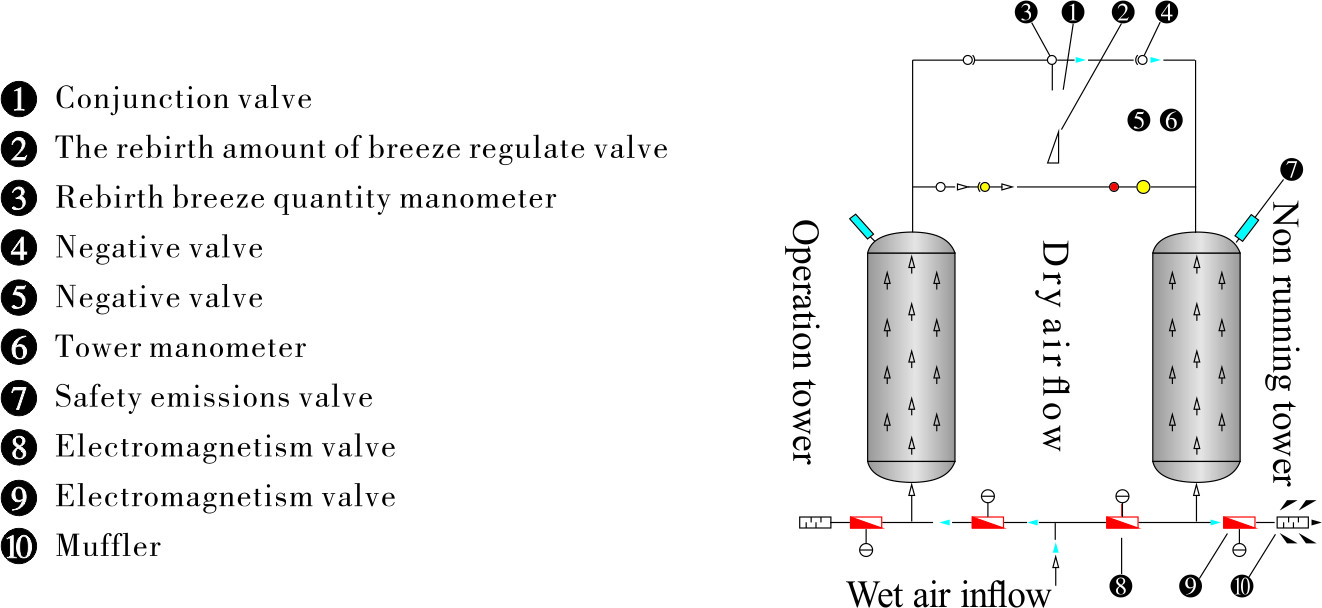

⊙ Adsorption dryer configuration schematics

⊙ High efficiency heat exchanger

➤ Adopting high strength thick copper pipe and oxygen-free welding

with quotient silver content electrode; long service life and high

heat transfer efficiency.

➤ Adopting anaerobic welding method, the system is free of

impurities and keeps the system clean. The whole series of copper

tubes are manufactured by mechanical expansion, which are closely

combined with fins, with low heat transfer impedance and high heat

transfer efficiency.

➤ The coil is cleaned by sound wave and there is no residual oil. It

is not easy for eel slices to stick dust, and no carbonization

occurs during welding.

➤ Adopt the anaerobic welding method to ensure the cleanliness of

the system.

⊙ Adsorption Dryers Compressor Specification

| Models | 5RD | 10RD | 20RD | 30RD | 50RD | 75RD | 100RD | |

| Air Capacity | Nm³/min | 0.8 | 1.35 | 2.6 | 3.6 | 6.9 | 10.7 | 14.4 |

| SCFM | 28 | 47 | 91 | 127 | 243 | 377 | 508 | |

| Suitable for air compressor | 5 | 10 | 20 | 30 | 50 | 75 | 100 | |

| Air inlet or outlet | 1/2″ | 3/4″ | 1″ | 1″ | 1½″ | 1½″ | 2″ | |

| Dimension | L (cm) | 60 | 94 | 102 | 107 | 112 | 117 | 122 |

| W (cm) | 40 | 50 | 60 | 60 | 70 | 70 | 70 | |

| H (cm) | 186 | 178 | 191 | 186 | 214 | 214 | 212 | |

| Total Weight (Kg) | 90 | 120 | 190 | 247 | 420 | 429 | 569 | |

| Models | 150RD | 200RD | 250RD | 300RD | 400RD | 500RD | 600RD | 700RD | |

| Air Capacity | Nm³/min | 21.4 | 28.4 | 34.5 | 42.7 | 59.5 | 70.8 | 79.3 | 106.2 |

| SCFM | 755 | 1006 | 1207 | 1507 | 2106 | 2506 | 2807 | 3759 | |

| Suitable for air compressor | 150 | 200 | 250 | 300 | 400 | 500 | 600 | 700 | |

| Air inlet or outlet | 2″ | 3″ | 3″ | 4″ | 4″ | 5″ | 5″ | 6″ | |

| Dimension | L (cm) | 122 | 180 | 180 | 204 | 234 | 234 | 244 | 296 |

| W (cm) | 70 | 80 | 80 | 80 | 90 | 90 | 95 | 100 | |

| H (cm) | 240 | 225 | 255 | 243 | 228 | 253 | 253 | 268 | |

| Total Weight (Kg) | 804 | 1024 | 1218 | 1413 | 2040 | 2405 | 2658 | 3550 | |

The biggest usage condition:A.Entrance

temperature 40℃ B.The air pressure 10Kg/cm³; Rebirth breeze

quantity 12%;

Girculation time be 5 minutes; Time of rebirth

is 4.5minutes;

Continous press time for 0.5 minutes; The

atmospheric pressure of the dewdrop temperature 40℃; The power

supply is 10 Ф 220V 50 Hz/60Hz.

⊙ Combined dryer

| SAD-600 Combined Compressed Air Dryer Processing air quantity:79.3 Nm³/min Work pressure :7 Kg/cm³ (MAX 10Kg/cm³) Compressor horsepower: 15 HP Air inlet and outlet caliber: 6″ Power supply: 3Ф 220V / 3Ф 380V Cooling water volume: 225 L/min Dimension: 280cm×140cm×180cm | SAD-600 Combined Compressed Air Dryer Processing air quantity: 169.7 Nm³/min Work pressure : 7 Kg/cm³ (MAX 10Kg/cm³) Compressor horsepower: 30 HP Air inlet and outlet caliber: 8″ Power supply: 3Ф 220V / 3Ф 380V Cooling water volume: 450 L/min Dimension: 350cm×170cm×225cm |

1. High Performance pneumatic Valves Oil-less pneumatic valves are

designed specifically for high temperature applications and feature

stainless steel internals and filled PTFE seats.

2. Low wattage heater with high temperature interlock Low-wattage

high incoloy sheathed heater for efficient regeneration. Heater

high temperature with interlock alarm provides continuous

monitoring of heater sheath temperature. The heater will

de-energize in a high temperature condition.

3. High Efficiency Centrifugal Blower Reliable, quiet generation of

purge air. Intake filter is positioned for convenient access to

facilitate filter element changeout.

4. High performanced desiccants Double fixed bed layers,

respectively filled with high performanced activated alumina and

molecular sieve.

5. Advanced PLC controller PLC Controlling system executes and

monitors all dryer functions, 7’’ Touch screen panel displays dryer

status.

6. Dew Point Display Highly accurate ceramic dew point sensor and

high dew point alarm.

7. Pressure Gauges Stainless steel gauges, located on each tower,

provide visual indication of pressure during drying and

regeneration processes.

8. Large Purge Mufflers Large mufflers minimize noise and include

built-in safety relief valves.