Beijing Silk Road Enterprise Management Services Co.,LTD |

|

Verified Suppliers

|

|

LFT-D Extrusion line for PA,PP, glass fiber and Carbon Fiber with output 200kg/hr

General Introduction of LFT

Long-fiberReinforce Thermoplastic(LFRT), the length of the fiber glass is bigger than 3mm, while the commercialized LFRT is normally 6-25mm.

The modulus of long fiber reinforcement is double than that of short fiber reinforcement, while impact tension is four times, can keep its function without any change under the temperature of minus 30℃

The excellent properties are as following:

We always focusing on new innovation on the LFRT/LFT-D. We have already done such turn-key project for some customers. The projects are LFRT compounding system, LFT-D,LFT-G and LFT-D-ILC.

Our Product Advantages:

1. Professional team working with you together

2. High quality twin screw extruders to make sure the stable extrusion

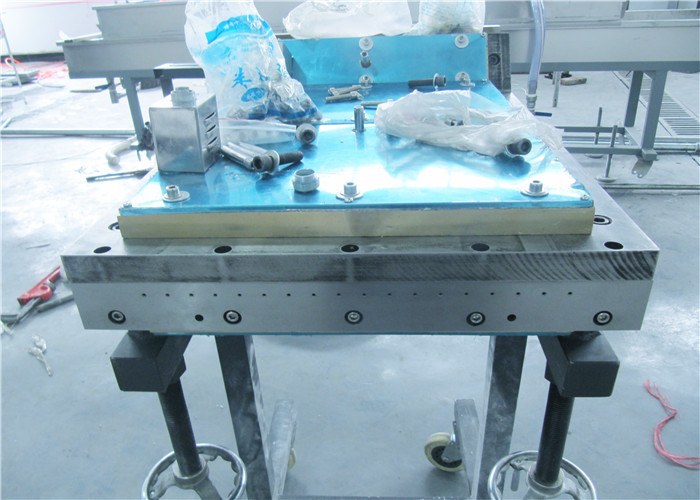

3. Perfect extrusion die head design to ensure the fiber can immerge into the melt and minimize the fiber floatation.

4. Perfect fiber pre-treatment system

5. Effective fast cooling system for the strands

7. Constant pulling machine

8. Good pelletizer to make sure the uniform granule size

9. Good controlling system for the whole line

10. Turkey projects are available here. One staion service for you.

Service:

Before-sale:

Introduce products in details

Recommend suitbale solution

Follwing customer for the technical, business communication

Testing before order is availble for customers

During manufacturing:

Providing layout and engineering conditions

Offerring screw plan and related documents

Inform the project processing status

Quality control from the production, purchasing and assembly.

Testing the machine, making it to the ideal status.

After-sale:

Provide installation,commissiong and training

Making customer profile including quotation details, contract,

technical documents, drawing, to make sure every machine customer

bought can get the information quickly and easily