CEBE GROUP HK CO.,LTD |

|

Verified Suppliers

|

|

WHY DO WE NEED HIGH QUALITY COMPRESSED AIR

Compressed air is an important power source widely used in industrial fields, and is the second largest power source after electricity.

Compressed air comes from the atmosphere, which contains a lot of dust, water vapor, impurities and so on. Unpurified compressed air will seriously wear pneumatic equipment, and cause blockage and corrosion of valves, pipelines, etc. It causes damage to production equipment and scrap of products, affecting normal production. Therefore, it is necessary to purify the compressed air it is essential. With many years of professional experience, Epsea not only focus on the research and development and equipment manufacturing in the field of compressed air purification, but also through our understanding and summary of the manufacturing industry, we can provide users in various industries with more economical and efficient comprehensive compressed air purification solutions.

HOW TO CHOOSE THE RIGHT COMPRESSED AIR PURIFICATION EQUIPMENT?

The requirements of modern industry for compressed air can be divided into the following aspects:

1) Pressure and flow requirements;

2) Requirements for dryness (i.e. water content or dew point temperature);

3) Cleanliness requirements (relatively complex, including: solids, oil mist, microorganisms, harmful gases, etc).

HOW CAN CLEANLINESS REQUIREMENTS BE ACHIEVED THROUGH FILTERS?

The filter plays a key role in the compressed air drying and purification system. The use of different filters can remove oil (including liquid, gas), solid impurities, microorganisms, harmful gases and other pollutants in the compressed air. In the compressed air drying and purification system, filters exist everywhere. In industrial production, the filter used by the compressed air system is often divided into several categories according to its use: oil removal filter, dust removal filter, sterilization filter and special filter.

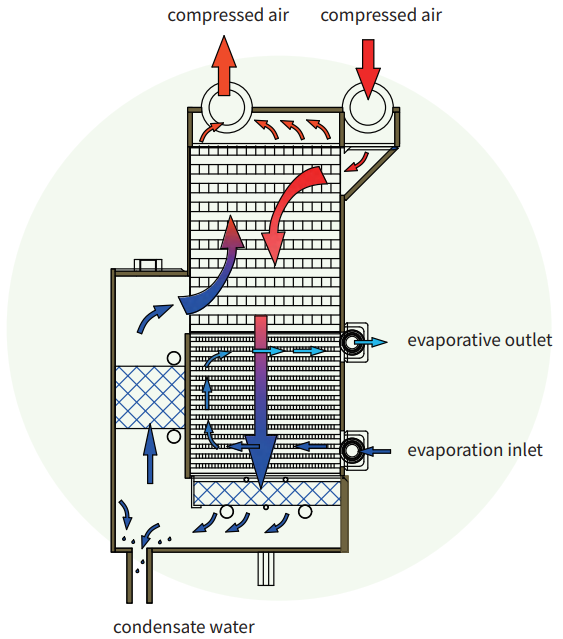

Patent Technology:3 in 1 Heat Exchanger System

1).Extreme Speed:Pre-cooling System

The unique structural design of the precooling channel ensures that the compressed air at the entrance is fully and quickly cooled. Ultra-low pressure loss makes the refrigeration system cycle run more efficiently.

2).High-efficiency:Evaporation System

The improved evaporation channel is developed so that the heat of the compressed air is fully absorbed by the liquid refrigerant. Absorbed, the refrigerant is completely "vaporized" back to the compressor suction port for the refrigeration system. In a cycle, the gaseous water in the compressed air is cooled and a large amount of liquid water is precipitated.

3).Dual Stage:Water Seperation System

Efficient gas-water separation contains crude. The two-channel structure is compressed into the water distributor. The air flow rate is reduced, the coarse water separation structure will completely separate a large number of liquid water, and the fine water separation. The structure will again separate some of the liquid water droplets carried by the airflow fluid drag force, ensuring that. Maximum separation efficiency, thus achieving a more stable dew point.

Technical Indicators

| Intake Temperature | Cooling | Ambient Temp | Pressure Dew Point | Working Pressure Range |

| 10~60℃ | Air Cooled | 2~40℃ | 2~7℃ | 0.6~1.3Mpa |

Advantages and guarantees:

01 Eco-friendly refrigerant · Double efficiency

R410a refrigerant is used, which is more efficient than R22 and does not damage the ozone layer.

02 System optimization · Reject ice jams

The smart energy hot gas bypass control system can maximize the cooling capacity of the combination, and accurately control the excess cooling capacity at the same time, that is, to ensure the dew point and not to block the ice.

03 Larger channel · Lower pressure drop

The specially designed vertical reverse flow heat exchanger can effectively control the pressure drop, so that the pressure drop is less than 0.2Bar, which can save the power consumption of the system for the user's direct connection.

04 New material · Professional corrosion resistance

Aluminum alloy materials used in the heat exchange system have good corrosion resistance, and the surface volume of aluminum is easy to produce A layer of dense and solid AL₂ 0₃ protective film, which can be very good. Protect the substrate from corrosion, effectively protect the compressed air into the heat exchange system will not produce secondary contamination.

05 Upgrade configuration · More stable dew point

Three-in-one high efficiency heat exchange system is equipped with a reverse flow heat exchanger with larger surface volume, which should be relaxed for various high temperature working conditions and more stable dew point.

06 Selected parts · Quality worry free

a. Self-developed refrigerated air dryer specially used micro-computer control device, which can control the start and stop of dryer and high temperature protection according to the change of system load;

b. Self-designed cooling condenser, thickened copper tube and hydrophilic aluminum foil, combined with famous brand high air volume external rotary blower, better heat dissipation effect and more durable;

c. The whole series adopts the joint venture brand refrigerant compressor, based on the various machine types, choose the most suitable high efficiency rotary or vortex compressor