Anping County Xinlu Wire Mesh Products Co., Ltd. |

|

Various applications including:

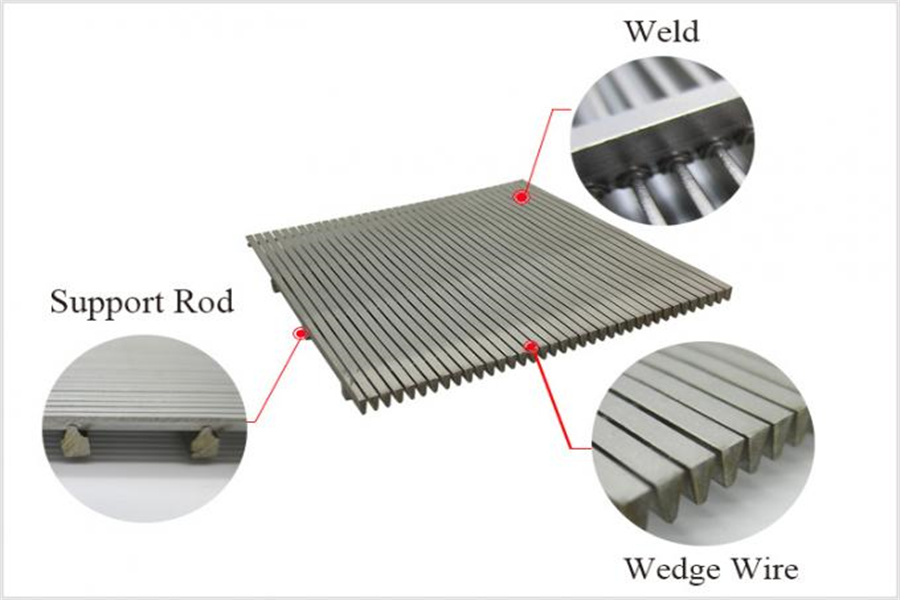

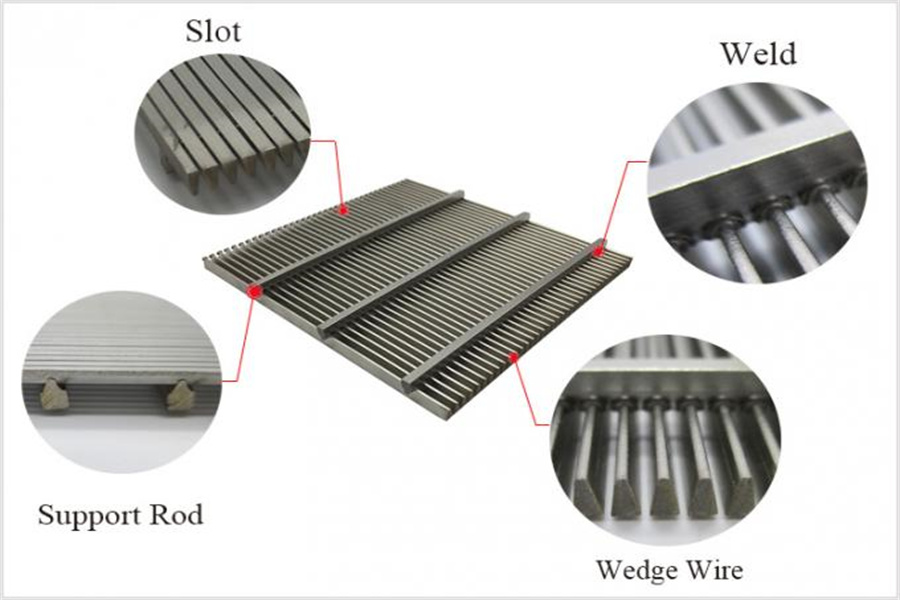

Slot opening usually at 90 degrees to flow direction. We will manufacture to your design requirement

| PROFILE WIRE | ||||||||

| WIDTH(mm) | 1.50 | 1.50 | 2.30 | 2.30 | 1.80 | 3.00 | 3.70 | 3.30 |

| HEIGHT(mm) | 2.20 | 2.50 | 2.70 | 3.60 | 4.30 | 4.70 | 5.60 | 6.30 |

| SUPPORT ROD | ROUND | |||||

| WIDTH(mm) | 2.30 | 2.30 | 3.00 | 3.70 | 3.30 | Ø2.5--Ø5mm |

| HEIGHT(mm) | 2.70 | 3.60 | 4.70 | 5.60 | 6.30 | ---- |

---------------------------------------------------------------------------------------------------------------

Our factory Xinlu Wire Mesh product co., Ltd located in Anping country, Hebei Province, China.

Our mainly products are: stainless steel vee sharped wire / wrap wire, johnson type screeen, water well screen / rod based wire wrapped screen, wedge wire screen, reverse wedge wire screen, stainless steel strainer pipe, v wire slot tube, perfect roundness well screen pipe, dewatering well screen, dewatering screen panel, wedge wire grating, v wire flat panel, screen nozzle, water and gas strainer nozzle, stainless steel filter nozzle, wedge wire support grids, sieve bend plate, v wire screens, ARC screen, filter bottom nozzle, stainless steel lateral screens, wedge wire filter candles, Rotary drum screens, strainer cylinder, sand control well screen, oil well screen, rod based continuous slot screens, header and hub laterals & hub radial laterals etc.

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.