WUXI JINQIU MACHINERY CO.,LTD. |

|

Verified Suppliers

|

|

3 in 1 Standard thinner material coil feeding line : uncoiler, straightener, and feeder

Model:

NCSF5

Usage:

For 0.3-3.2 mm thinner sheet thickness coil uncoilling, straightenning, and feeding

Characteristic:

1. This machine 3 in 1 adopts coil bottoom inlet mode. It is

suitable for 0.3--3.2 mm thickness material with 0-1300mm width

coil punching uncoiling, straightening and feeding

2, press arm with pneumatic mode can avoid coil loose,

and mathced with material inlet plate to press the coil head

flat, and let the material smoothly ienter into the machine.

3, we use 11 pcs of straightening rollers, and rollers

material is high strength bearing steel GCr15 with quenched

and tempered by high frequency treatment, surfaace hard chrome

hardness can reach HRC60 ~ 62 degrees, the dimensional accuracy

0.01mm, which strictly ensures straighening roller surface

smoot, during the straightening procee, to make ensure the coil

material surface performance

4, The materil on the uncoilling frame is controlled by

below photoelectric device, the straightening head

can make material straightening, and at the same time, send

the length-setting materail to the punching or press machine, and

throught the punching machine gives signal, the uncoiler looses the

material, and press down, and guide material

5, the auxiliary device is operated by air or electricity as the

power source, simple operation, easy maintenance, after debugging,

the failure rate is low.

6. The feeding trolley device can be used to save the feeding time,

improve work efficiency, save manpower and achieve manual

operation.

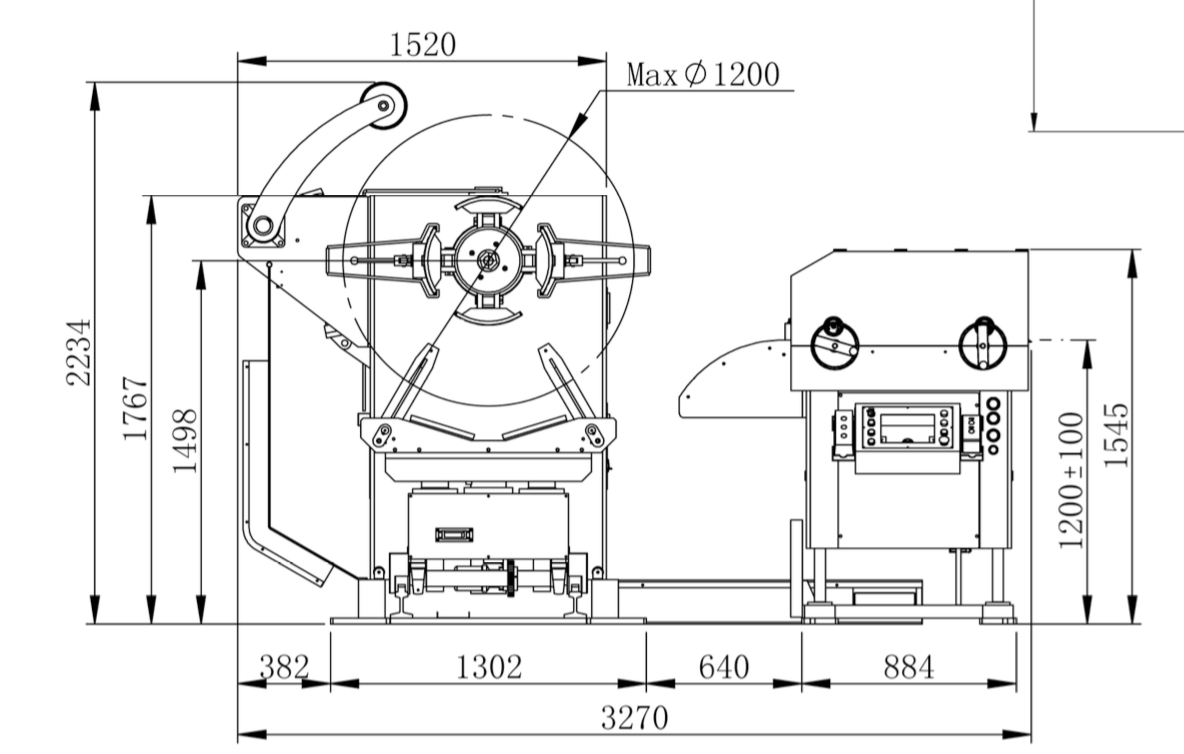

Machine Overall Size Drawing:

Stranghtening Performace Charte:

| Model | material thickness [mm] | ||||||||

| 0.3 | 1.3 | 1.6 | 2.0 | 2.3 | 2.5 | 2.8 | 3.2 | ||

feeding width [mm] | NCSF5-400 | 400 | 300 | 230 | 150 | 110 | |||

| NCSF5-500 | 500 | 400 | 360 | 300 | 230 | 150 | 110 | ||

| NCSF5-600 | 600 | 470 | 360 | 300 | 230 | 150 | 110 | ||

| NCSF5-800A | 800 | 480 | 360 | 370 | 320 | 250 | 220 | ||

| NCSF5-1000A | 1000 | 430 | 350 | 330 | 290 | 250 | 200 | ||

| NCSF5-1300A | 1300 | 430 | 350 | 330 | 290 | 250 | 200 | ||

Machine Models:

| Model | NCSF5-400A | NCSF5-500A | NCSF5-600A | NCSF5-800A | NCSF5-1000A | NCSF5-1300A |

| Material width[mm] | 50~400 | 50~500 | 50~600 | 70~800 | 70~1000 | 70~1300 |

| Material thickness[mm] | 0.3-3.2 | |||||

| Max coil weigth [kg] | 3000(5000) | 5000(7000) | ||||

| coil inner diameter[mm] | ¢508 | |||||

| coil outer diameter [mm] | ¢1200 | ¢1400 | ||||

| max speed[m/min] | 16 | 22 | ||||

| feeding accuracy [mm] | ±0.15 | |||||

| straightening rollers [mm] | ¢48×11 pcs(up 6/ bottom 5) | ¢48×7 pcs( up 4/ bottom 3) | ||||

| feeding rollers [sets] | 1 | |||||

| feeding heights[mm] | 1150±100 | 1200±100 | ||||

| voltages | 220VAC 60HZ/AC380v 50HZ | |||||

| air pressure[kg/cm2] | 5 | |||||

| coil expansion mode | hydraulic | |||||

| servo motor[kw] | AC3.0 | AC4.4 | AC5.5 | |||

uncoiler motor [kw] | 1.5(2.2) | 2.2(3.7) | ||||