WUXI JINQIU MACHINERY CO.,LTD. |

|

Verified Suppliers

|

|

aluminum wine cap making line includes below parts:

this whole wine bottle aluminum cap line includes mechanical press/punching machine, muti-cavity punching die--one time punching forming die, cap aluminum coil holder frame, aluminum coil brush oil, blow finished cap, pull coil material servo control system, pull coil material, waste/useless material coilling, separate aluminum cap and waster/useless ring--the caps come out, the waster rings stay in the collection box, die protection system: during punching, it can protect die, if any cap is wrong, this system will stop the machine to protect die

Usage:

In China, only us can produce the whole line for wine cap and medicine cap. This line needs a lot of experiece to make let punching and feeding line cooperate very well. We are the most professional factory, in China, 80-90 cap makers use our machine.This cap professional line is specially designed for plastic mold, medicine bottle cap, wine bottle cap, cosmetic cap, it is used with high-speed punching machine

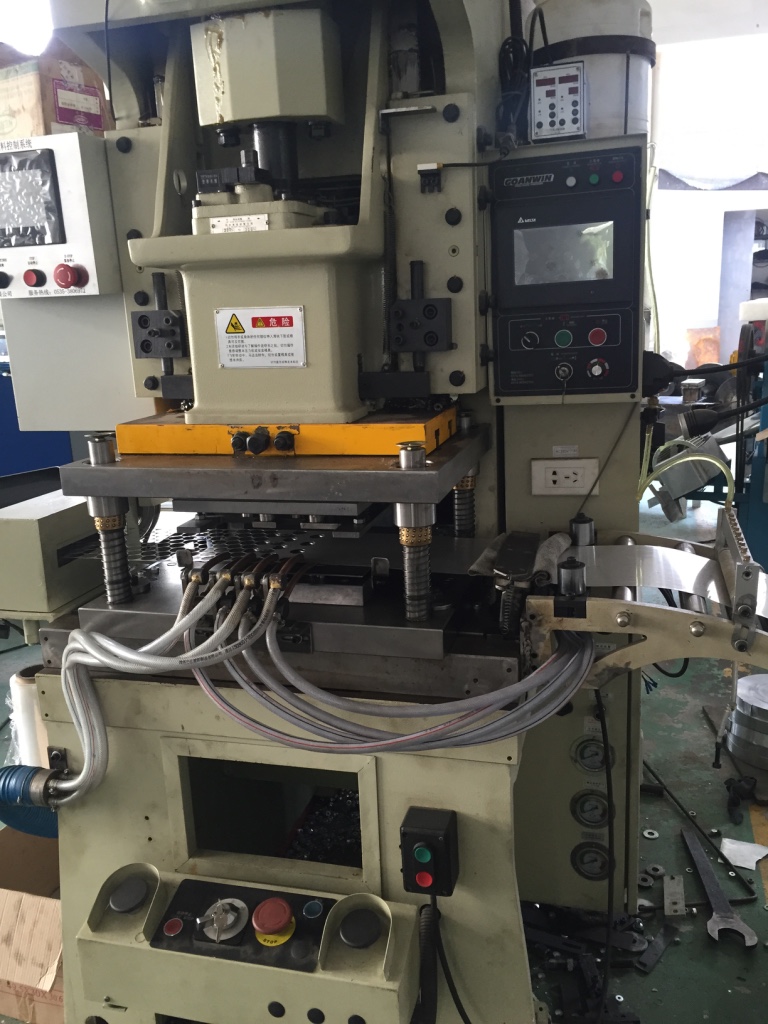

1)Punching machine/mechanical press machine details

| Item | 45 | |||

| L | S | |||

| Nominal pressure | kN | 450 | ||

| Nominal pressure stroke | mm | 3.2 | ||

| Stroke of slide | mm | 100 | 70 | |

| Stroke | Variable | spm | 60-90 | 70-110 |

| Single | spm | 80 | 100 | |

| Max. die set height | mm | 270 | 285 | |

| Die height Adjustment | mm | 60 | ||

| Depth of throat | mm | 230 | ||

| Distance between uprights | mm | 500 | ||

| Bottom size of slide | L-R | mm | 410 | |

| F-B | mm | 340 | ||

| Hole for punch shank | Diameter | mm | Φ50 | |

| Depth | mm | 60 | ||

| Size of table | L-R | mm | 810 | |

| F-B | mm | 440 | ||

| Thickness | mm | 110 | ||

| Size of opening in table | Diameter | mm | Φ150 | |

| Single speed motor power | kW | 5.5 | ||

| Overall dimension | L-R | mm | 1080 | |

| F-B | mm | 1410 | ||

| Height | mm | 2300 | ||

| Total weight | kg | 4000 | ||

2) other devices for the cap making line and making steps:

Wine cap making Step 1:cap punching die with 6 cavity---it means one stroke, we can get 6 caps, max we can produce 16 caps

Wine cap making Step 2:Cap aluminum coil holder frame

Wine cap making Step 3:Aluminum coil brush oil

Wine cap making Step 4:-Blow cap

Wine cap making Step 5:pull coil material servo control system

Wine cap making Step 6:Pull coil material and waste material coiling

Wine cap making Step 7:separate aluminum cap and waste ring,The caps come out, the waste rings stay in this cabilet

Wine cap making Step 8:Die protection system: during punching, it can protect die, if any cap is wrong, this system will stop the machine to protect die

3)More photos