QINGDAO SHENGHUALONG RUBBER MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

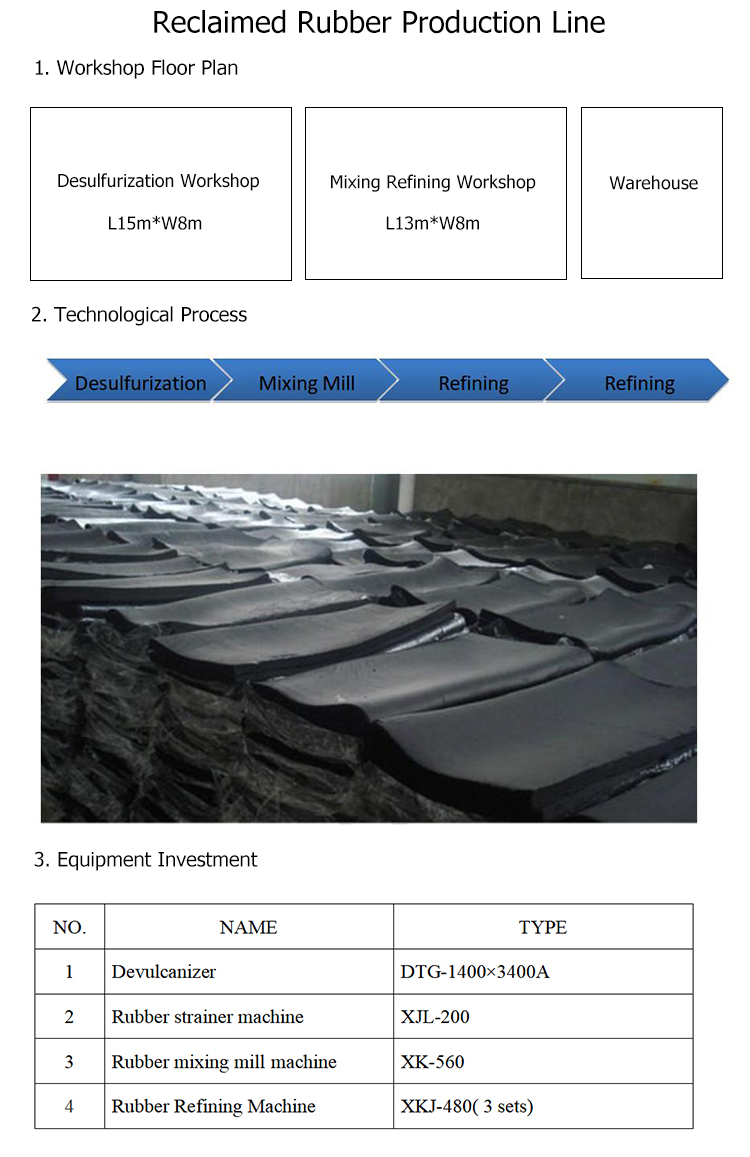

High Performance Reclaimed Rubber Production Machine Rubber Powder Devulcanizer Machine

Model & Specifications | DTG-1800×3300A |

Interior Diameter of Container(mm) | 1800 |

Working Length of Container(mm) | 3300 |

Working Pressure 0f Container (Mpa) | 4 |

Working Temperature (Cº) | 250 |

Heating Medium | Steam-gas |

Major Pressurized Material | 16MnR |

Container Classification | Q345R |

Rotating Speed of Mixing Shaft(r/min) | 10 |

Main Motor Power(KW) | 55 |

Heating Method | Electrical Heating |

Total Cubage (m³) | 10 |

Overall Dimension(mm) | 7150*2950*2150 |

Weight(Kg) | 16000 |

Rubber Refiner is rolling after desulfurization rubber powder, change the physical form, and remove hard impurities contained in the reclaimed

rubber. Before and after the roll surface is smooth, like a waist drum. Refining machine during operation, It can be hard rubber impurities from the roller center to both ends. Impurities gathered at the edge of the roller,

Then use knife remove to impurities on the edge of roller. Roll adopts the vanadium titanium alloy chilled cast iron, the surface is hard wearresisting, inner cavity machining, the roll surface temperature

uniformity. The machine is equipped with an emergency brake, When emergency occurs, pull the pull rod, the machine immediately brake, safe and reliable. Driving system consists of NGW hardened tooth surface reducer, compact structure, low noise, high efficiency, longservice life.

Type Technical parameter | XKJ-480 |

| Front roll diameter(mm) | 480(Waist-drum) |

| Rear roll diameter(mm) | 612(Waist-drum) |

| Working length of rolls(mm) | 1200 |

| rear roll surface speed(m/min) | 67 |

| Friction ratio | 1:1.27 |

| Max. nip(mm) | 15 |

| Motor power(KW) | 110 |

| Overall dimension: L×W×H | 6350×2800×2000

|

Electrical

| NO. | NAME | TYPE | Motor power (kw) |

| 1 | Feeding screw conveyor | 7.5 | |

| 2 | Platform | ||

| 3 | Devulcanizer | DTG-1400×3400A | 55 |

| 4 | Cooling machine | 18 | |

| 5 | Rubber strainer machine | XJL-250 (2 sets) | 220 |

| 6 | Rubber Refining Machine | XKJ-480(6 sets) | 660 |

| 7 | Converyer belt | 6 | 52.8 |

| 8 | Curly,weighting, packing | 3 | 48 |

| Total power :1061.3kw | |||