SHANGHAI ROYAL TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Royal technology has developed and built the whole supply chain for Car LOGO board PVD metalizing service. From mold design & manufacturing, thermal vacuum forming process, UV curing base/top coatings; PVD chroming metalizing till LED lighting assemble, we are able to provide a complete turn-key coating solution.

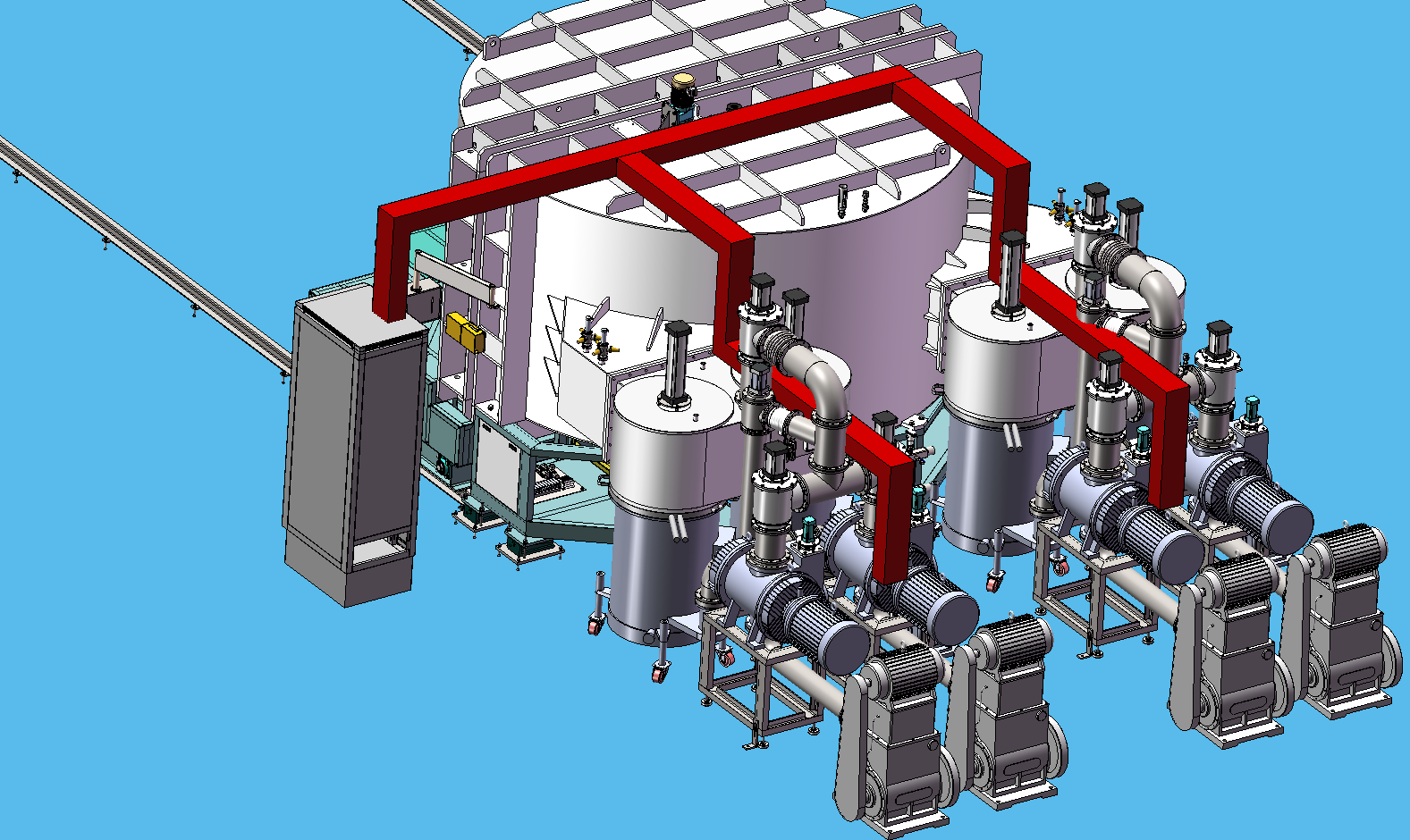

This series of high vacuum metallizing equipment is customized

designed system for manufacturing high quality of mirror finishing

and see-through (transparent effect) finishing thin films on 3D

automotive acrylic billboard.

With the PVD thermal evaporation technology, which deposits high

reflection film on PMMA (Acrylic) surface, gives an outstanding

coating layers as below: during the day time, sign symbols look

like solid metal ( stainless steel effect); while at night, they

are illuminated ( LED light inside is installed ) from front, back

and side views.

Applications:

3D LED illuminated Automobile LOGO and sign symbols, PC/PMMA Chrome

Coating, Aluminum/Silver/Copper/ SS wires Metalizing, PC panel

sheets of mirrors.

Technical Advantages

With PVD vacuum metallizing technique, the film thickness can be controlled, the coating process is environmentally friendly, an ideal coating solutions to replace the conventional Chrome plating process.

Besides, more benefits:

1. Durable, life time is up to 5~8 years, even in outdoor.

2. Easy assemble and maintenance. With screws mounting or hang-up

method.

3. Safe and reliable. The PMMA material makes it much lighter in

weight than metal logos, highly reduce the risk of injuries from

falling down accident.

4. Outstanding aesthetic finishing: during the day time, the car

sign symbols look like solid metal ( stainless steel effect); while

at night, they are illuminated

( LED light inside is installed ) from front, back and side views.

Royal Technology successfully developed 3 models metallizing system

to serve the worldwide coating services centers: South Korea,

Mexico, and China countries.

Model A: top coating structure

RTEP3600

Advantages

1. The door located in the railway track, sliding model, easy to

operate and very convenient for loading/unloading

1.1 Max. product size: 3000mm

1.2 Suitable for see-through finish

2. The unique rotary rack and evaporation system design to

guarantee a high uniformity.

2.1 The height from substrate to evaporation source can be adjusted

flexibly ;

2.2 Evaporation sources distance can be adjusted;

2.3. Three groups evaporation sources for a perfect full area

coating.

RTEP2200

Advantages

Model B: Cylindrical Chamber with Planetary Rotary System

RTEP2500

Advantages:

Insite

The door located in the railway track, sliding model, easy to operate and very convenient for loading/unloading.

The unique rotary rack and evaporation system design to guarantee a high uniformity.

-The distance from substrate to evaporation source can be adjusted flexibly;

– Evaporation sources distance can be adjusted;

– The substrate holder is sliding forward/backward in chamber.

– The 2nd substrate trolley for option to enhance efficiency.

Technical Specifications

| Model | RTEP6600 | RTEP4500 | RTEP3600 | RTEP2500 | RTEP2200 |

Standard Applications | Car logo and symbols billboard, bumpers, bezels and other plastic large parts for vacuum metallizing. Cr / NiCr / Al metallizing, from see-through to mirror finishing effect, programmable control coating process. | ||||

| Deposition Chamber | Cubic | Cubic | Cylindrical | Cylindrical | Cylindrical |

| Chamber Dimensions (L*W*H) mm | 6600*1300*3800 (32.6 m³) | 4500*1300*3200 (18.7 m³) | φ3600*1700 (17.3 m³) | φ2500*2500 (12.3 m³) | φ2200*1500 (5.7 m³) |

Project Location and Built Time | China, 2014 | China, 2015 | Mexico, 2014 | China, 2014 | South Korea, 2015 |

| Max. size of Loading (mm) | 6000 | 4000 | 3300 | 2000 | 2000 |

| Max.Total Power (KW) | 300 | 200 | 200 | 200 | 100 |

Average Power Consumption (KW) | 150 | 100 | 100 | 110 | 60 |

| Cycle Time (minutes) | 30 | 25 | 25 | 20 | 20 |

| Flexible configurations: the machine is set according to coating processes and customer’s requirement. | |||||

Performance

A. Ultimate Vacuum Pressure: better than 8.0×10-4 Pa

B. Operating Vacuum Pressure: 1.0×10-2 Pa.

C. Pumping down Time: from 1 atm to 8.0×10-3Pa≤15minutes

( @room temperature, clean and unloading)

D .Leaking Rate: 9.0-5 Pa m³/ sec. Or better than 0.67Pa in 1 hour

after shut down the machine from ultimate pressure.

E. Deposition Materials: Al, Cr, Sn, SS, Cu, Au, Al, In, Sn … etc.

F. Evaporation Sources: Tungsten filament, boat, basket etc.

G. Operating Model: Full Automatically /Semi-Auto/ Manually

H. Safety Circuitry and Interlocks: numerous safety interlocks to

protect operators and equipment ( water, current etc.)

see-through effect

see-through effect

Built Time: Since 2015

Location: China, Mexico and South Korea

Please contact our technicians today for more specifications. We provide total production solutions.