SHANGHAI ROYAL TECHNOLOGY INC. |

|

Verified Suppliers

|

|

PVD Gold Plating Jewelry Equipment

Advanges of PVD Gold Coating Jewelry

Durability

Benifits pf PVD Gold Plating Process

Eco-friendly, no toxic wastes generated in the whole process

High uniformity of thickness

With Ion plating technology, more scratch resistant

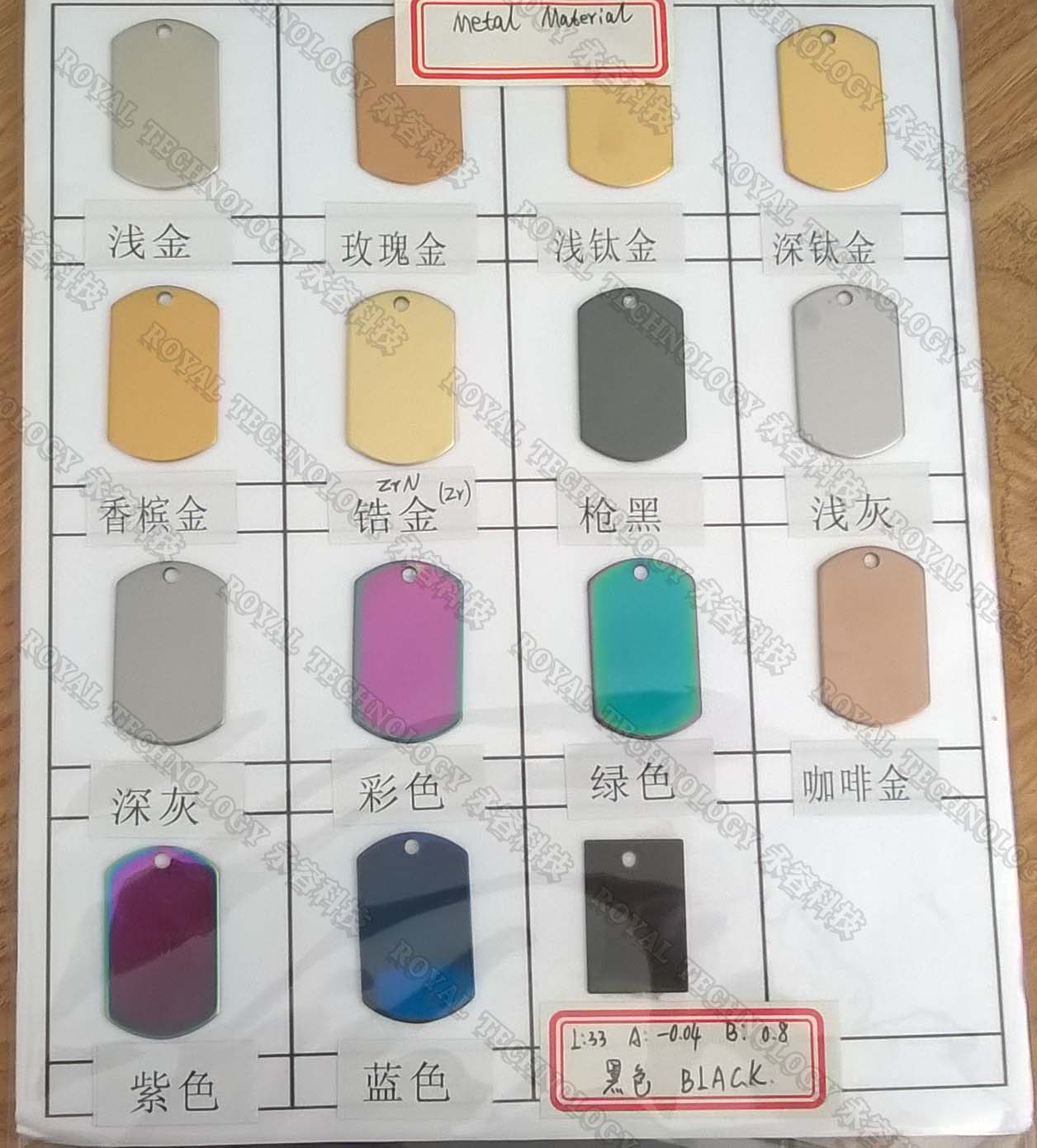

More designed colors, more feasiable and flexible

ABSTRACT

Decorative hard coatings have to meet variety of requirements such as attractive colors and high wear resistance. For luxury consumer goods such as watch components, writing instruments or spectacles, some manufactures want to maintain both the high wear resistance of PVD and the “gold plate” label which provides the product with a “high quality” image. So a 3 to 5 μm layer of gold plating must therefore be deposit onto a (TiN+Au) PVD layer. This multi-layer method creates a high level of internal stress leading to adhesion defects. A complete process has to be set up in order to reduce the internal stress leading to adhesion defects.

WHY A COMBINATION OF “ GOLD PLATING” AND PVD?

Gold is still the most widely used color for decorative applications, and this is unlikely to change. For gold colored decorative hard coatings, the current state-of-the-art technique involves depositing a thin top layer of gold alloy onto a basic hard coating consisting of TiN. Unfortunately, gold alloy sputtering is a non-reactive process and for each different gold alloy a very definite color is obtained (for deposition temperatures around 200℃)

This process must not alert the final gold color without changing the gold target. Some manufactures also want to maintain both the high wear resistance of PVD and the “Gold plated” label which provides the product a high quality image. For these three seasons:

High wear resistance of the PVD layer

Gold plated label

Wide range of gold color provided by the final electroplating

A reliable process must now be found which allows a thick (3 to 5 μm) of electroplated gold onto a TiN+Au layer.

PVD Gold Plating Machine Specificaitons

| MODEL | RTAS1000 | ||||||

| TECHNOLOGY | Magnetron Sputtering + Arc Ion plating | ||||||

| MATERIAL | Stainless Steel (S304) | ||||||

| CHAMBER SIZE | Φ1000*H1000mm | ||||||

| CHAMBER TYPE | Cylinder, vertical, 1-door | ||||||

| SPUTTERING SYSTEM | Exclusively design for thin black film deposition | ||||||

| DEPOSITION MATERIAL | Aluminum, Silver, Copper, Chrome, Stainless Steel, Nickel, Gold, TiAl, Au alloy, Ag etc. | ||||||

| DEPOSITION SOURCE | 1 DC sputtering + 1 Ion Source + 6 arcs | ||||||

| GAS | MFC- 4 ways, Ar, N2, O2, C2H2 | ||||||

| CONTROL | PLC(Programmable Logic Controller) + | ||||||

| PUMP SYSTEM | SV200B - 1 set (Leybold) | ||||||

| WAU501 - 1 sets (Leybold) | |||||||

| TRP36 - 1 set | |||||||

| Turbo Molecular Pump: 1 set | |||||||

| PRE-TREATMENT | Sputtering / Bias power supply: 12 KW | ||||||

| SAFETY SYSTEM | Numerous safety interlocks to protect operators | ||||||

| COOLING | Cold Water | ||||||

| POWER ELECTRICAL | 480V/3 phases/60HZ ( USA compliant) | ||||||

| 460V/3 phases/50HZ ( Asia compliant) | |||||||

| 380V/3 phases/50HZ ( EU-CE compliant) | |||||||

| FOOTPRINT | L3000*W3000*H2000mm | ||||||

| TOTAL WEIGHT | 7.0 T | ||||||

| FOOTPRINT | ( L*W*H) 5000*4000 *4000 MM | ||||||

| CYCLE TIME | 30~40 minutes (depending on substrate material, substrate geometry and environmental conditions) | ||||||

| POWER MAX.. | 60KW | ||||||

AVERAGE POWER CONSUMPTION (APPROX.) | 30 KW |

Other IP colors

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.