SHANGHAI ROYAL TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Thermal Resistance Evaporation Web Coater / Intuitive PLC IPC Control Roll to Roll Vacuum Web Coating Unit

Thermal Resistance Evaporation Web Coater General Information

Royal has introduced Roll to Roll Web coating system from

Darly Custom Technology. Inc. to serve our customers in flexible

films coating industries. Darly, with more than 25 years’

experience in web coating technology and multi-layer deposition, is

committed to providing the most innovative and reliable coating

solutions in the area of electronic paper, ITO film, flexible

circuits, photovoltaic, medical strips and RFID. This highly

versatile machine is designed to meet the specialty coating and

narrow web production demands of 21st century technology.

Thermal Resistance Evaporation Web Coater Key Features

1. Multiple source capability to enable deposition of metals,

alloys and dielectric materials in one pass without breaking

vacuum.

2. Divided chamber allows for variable pressure in the deposition

zone to accommodate thermo resistance, sputtering or E-beam

coating.

3. Precision web handling mechanism using A.C. Servo motor drives

for accurate control at any line speed.

4. Reversible web direction enables multiple layer deposition

without breaking vacuum.

5. In line optical and/or resistance coating detection monitors

linked to the deposition controls for precise deposition

uniformity.

6. Provisions for optional process equipment such as pre-treatment,

post-treatment or printing devices.

7.Compact design for easy installation using minimal floor space.

DARLY-RMC Specifications

| Model Number | M-500 | M-850 | M-1250 | ||||

| Coating Width | 450mm | 800mm | 1200mm | ||||

| Maximum Roll Diameter | 600mm | 600mm | 600mm | ||||

| Maximum Web Speed | 1000fpm | 1000fpm | 1000fpm | ||||

| Minimum Web Speed | 100fpm | 100fpm | 100fpm | ||||

| Number of Boats | 6 | 10 | |||||

| Average Power Consumption | 100KW | 130KW | 140KW | ||||

| Average Water Consumption | 36gpm | 45gpm | 53gpm |

Thermal Resistance Evaporation Web Coater High Lights

The M-Series tool will provide the following key features:

A. Compact design featuring a machine small footprint.

B. Deposition at high vacuum pressure for maximum deposition rate

and uniformity.

C. Plasma pre-treater optional for better adhesion require.

(Optional)

D. Optical density thickness monitor for metal deposition control.

E. Bi-directional web winding design that enables deposition of

unlimited layers without breaking vacuum.

F. Precision web handling mechanisms. No web scratches or wrinkles.

Roll rewind edge alignment within 3mm at one winding pass.

G. AC Inverter web drive system for accurate control of multiple

web speeds.

H. Stable wire feed and boats control.

I. Intuitive PLC and IPC control.

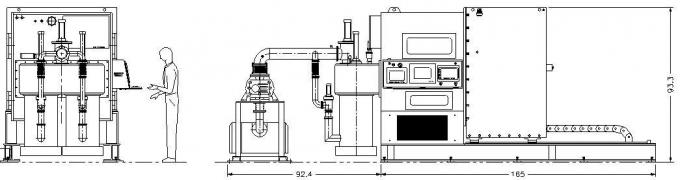

Thermal Resistance Evaporation Web Coater Layout Drawing

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.