Henan Zhongke Engineering & Technology Co., Ltd. |

Active Lime Production Line Lime Calcination Rotary Kiln Lime Kiln

Henan Zhongke Engineering & Technology Co., Ltd. is specialized in large and medium-sized series of mining machinery, metallurgical machinery, building materials equipments, cement equipment and rotary kiln. R&D, production and marketing into a joint-stock enterprise, our company is headquartered in Zhengzhou Country’s High-tech Industrial Development Zone, which consists of three branches, a research and development department.

Rotary kiln has simply structure, easy operation in producing, less wearing parts, high efficiency,it's used in the cement plant to calcine high grade cement, at the same time can be used in metallurgy,chemical,constructure ect. rotary kiln features in strong structure, stable operation, high-quality products from the kiln, and we can offers advanced efficient shaft preheater, five-grade cyclone preheater.

| Design Capacity(t/d) | 150 | 300 | 600 | |

| Product | Active Lime | Active Lime | Active Lime | |

| Pre-heater | Vertical Pre-heater | Vertical Pre-heater | Vertical Pre-heater | |

| Rotary Kiln | Size(m) | Φ2.5×40 | Φ3.3×50 | Φ4×60 |

| Effective Volume(m3) | 142 | 292 | 575 | |

| Burning temperature | ≤1250 | ≤1250 | ≤1250 | |

| Cooler | Grate Cooler | Grate Cooler | Grate Cooler | |

| Fuel | Gas Coal Dust | Gas Coal Dust | Gas Coal Dust | |

| Heat Consumption (kJ/kg Cao) | 5000-5300 | 5000-5300 | 5100 | |

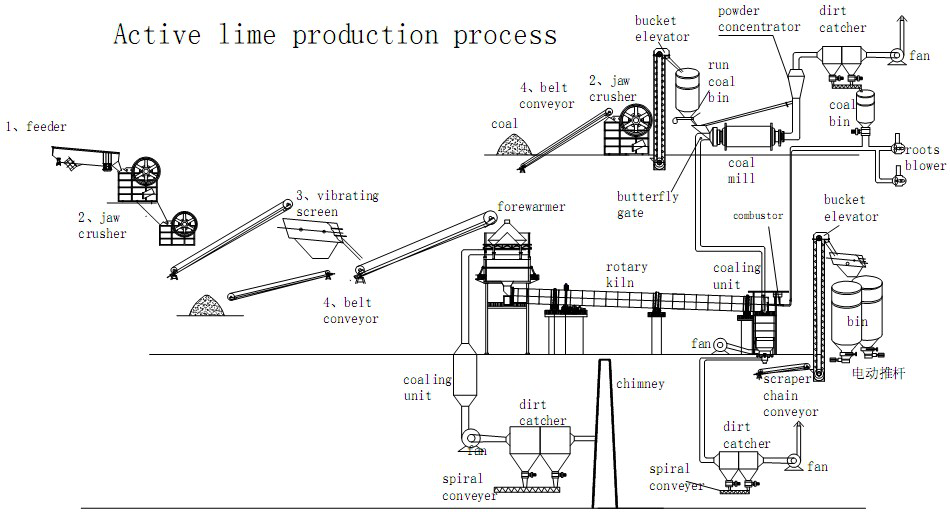

Process flow introduction: Qualified limestone is deposited in the

storage bin, hoisted by the elevator and transported into the top

bin of preheater. The top storage bin of the pre-heater is

consisted of top and bottom level gages controlling the feeding.

And then through the feed tube the limestone is distributed

uniformly to all the inside chambers of the pre-heater.

The limestone in preheater is heated to about 900°C by 1150°C kiln

gas, about 30% decomposition, pushed into rotary kiln by the

hydraulic push rod, and sintered and decomposed into CaO and CO2 in

the roatary kiln. After decomposition, the produced limestone goes

into the cooler, cooled down to 100°C by the entered cold air and

discharged out. The 600 ° C hot air after heat exchange goes into

the kiln and combusts with gas. The Exhaust gas goes into the bag

filler through draught fan when added into the cold air, and enter

the chimney through the exhaust fan.

The lime out of the cooler is transported into lime storehouse by

vibration feeding machine, chain conveyor, bucket elevator, belt

conveyor according to the customer’s request for whether making the

screening other procedures.