Cangzhou Famous International Trading Co., Ltd |

|

Verified Suppliers

|

|

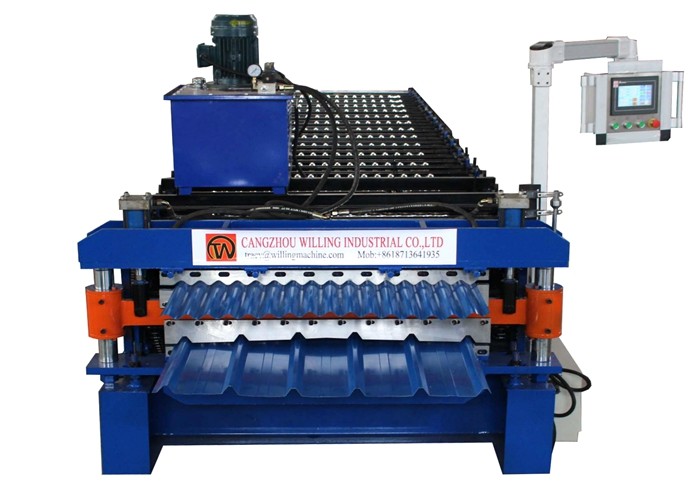

Metal Building Applicable Color Coated Roof Tile Roll Forming Machine

This Metal Building Applicable Color Coated Roof Tile Roll Forming Machine is a roll forming machine that used to make metal building roof tiles or wall panels. it is a very easy operated machine with PLC control and set. The applicated raw material could be color coated steel, aluminum, alumzinc coated steel and galvanized iron . Thickness of raw metal coil could be 0.4-1.1mm

Well, the formed profiles can be used as roof tile, fence, as well as wall panel for metal consttruction. In order to produce very good and beautiful

Metal Building Applicable Color Coated Roof Tile. Before the roll forming machine be fabricated we must check carefully with the customer what quality roof tiiles that they suuposed to make, As more roller stations will be considered to use to produce better quality roof tile.

| No. | Item | Description |

| 1 | Coil | Galvalume, Galvanized, PPGI, Aluminum |

| 2 | Raw Material Thickness | 20-30 GA |

| 3 | Working Speed | 3-4m/min ( not including the cutting time) |

| 4 | Roller Station | 16 Raws |

| 5 | Dimension (L*W*H) | according to the dimensions of profile |

| 6 | Machine Weight | 5800 KG |

| 7 | Electrical Control System | Delta PLC (can be customized) |

| 8 | Drive Motor Power | 7 KW |

| 9 | Hydraulic Station Power | 5 KW |

| 10 | Power Supply | 380V, 60HZ, 3 PHASES(can be customized) |

| 11 | Cutting Accuracy | ±2 mm |

| 12 | Driving Mode | Single Chain 1 inch |

| 13 | Material of Shaft | 70 mm 45#steel forged |

| 14 | Material of Roller | 45# Steel Finish Machining, Plated Hard |

Structure introduction

(1) Manual uncoiler

It is used to support the steel coil and realize the uncoiling by

means of rotatory movement. The steel coil is uncoiled manually.

The capacity of this uncoiler is 5 Ton, and it is capable for most

of the cases. This equipment is suitable to process the steel coils

with 508mm of ID.

(2) Feeding

Receiving the raw material (steel sheet), it guarantees the

products are neat, parallel and everything is uniformity. Please

refer to the equipment regulation for knowing the function of

locate angle iron.

(3) Machine material

In order to get high quality product, our machine adopts welded

steel frame structure, AC frequency conversion motor reducer drive,

chain transmission, heat treatment.

Roller material: bearing steel with heat treatment

(4) Shearing mechanism

It adopts hydraulic station and automatic cut to length system to

realize the stably cutting of certain length of products.Material

of the cutting blades: GCr12, processed by heat treatment

(5) Hydraulic system

It is derived by a Gear Pump. After filling the hydraulic oil into

the hydraulic oil tank, the pump could drive the hydraulic cylinder

to realize the cutting function.

The system includes a set of hydraulic tank, a set of a Gear Pump,

two hydraulic pipes .and two sets of Solenoid Valves.

Hydraulic oil :40#

Guarantee

1. Guaranteed against malfunctions due to manufacturing defects

for1 years after date of purchase except Electrical parts.

2. Repairs will not be performed even during the guarantee

period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

Payment terms

40% in advance as down payment

60% is paid before the shipment is processed

Delivery

FOB: Tianjin Xingang Port

The Delivery Time: 30 days after the down payment is received.