1. Main speficication:

1

| Suitable Material | GI |

2

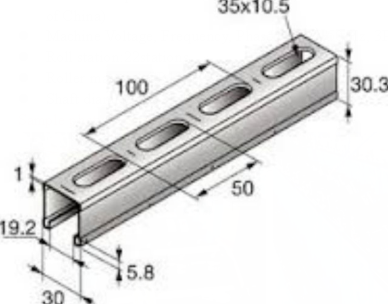

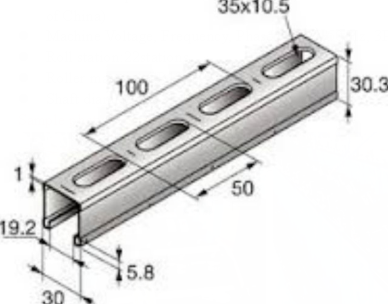

| Width of the raw material | Base on profile |

| 3 | Thickness | 1.5-2.5mm |

2. The Chart of Process Flow

Uncoiler— Flatten—Servo Feeding& punching—Roll

Forming—Rectify—Fly Saw Cutting—Out table

3. Specification of Components

| No | | Technical Specification & Remark |

| 1 | 3T manual un-coiler | - Width of feeding: 350mm

- Capability: 3 Ton

- Bound of expand &fight: 380mm—520mm

- Mode of expand &fight: inner expand &fight by manual

- Quantity:1

|

| 2 | Leveling part | - Flattener roller: upper is 4 rollers, down is 5 stations(total is 9

rollers)

- Diameter of flattened shaft:¢70mm, material is 40CR, hardening and

tempering

- Max leveling raw material width: 300mm

- Leveling raw material thickness: 1-2.5mm

- Power: 4KW AC motor

|

| 3 | Servo feeding& punching machine | - Servo feeding system

- This system adopt servo feeding to make high speed and precision

- Servo power: 2.9KW

- Servo brand: YASKAWA

- Quantity: 1

- 80T JH21-80 punching machine

- Punching station: 1 station with 6 holes

- Punching model: punching press

- Punching tooling base material: JIS S45C steel

- Punching tooling set material: SKD11

- Number of punching mould: 1set

- Punching dies material: SKD11

- Hardness of punching tooling set: HRC58-62

- Max punching sheet width: 300mm

- Punching machine carrying capacity 80T

- Brand of punching machine: Yang Li

- Main motor power: 7.5KW, Siemens

- Punching control cabinet: available

|

| 4 | Roll forming | - Roll station:26stations +1 station of torque head

- Roller material: Cr12 with heat treatment, HRC 58-82, surface with

chrome

- Shaft diameter: ¢85mm material: 40CR, HRC 250-280

- Main motor: 45KW

- Forming speed: 15-20m/min

- Machine drive part will be covered with protective cover

|

| 5 | Fly saw cuttings system | - Cutting after forming: Cut the sheet after roll forming to required

length

- Material of blade: Cr12MOV, 58-62 HRC hardness

- Cutting power by hydraulic,7.5KW

- Servo power: 3KW Yaskawa

- Working pressure:16Mpa

- Cutting and servo in the middle under cutting

- Length measuring: Automatic encoder length measuring

- Tolerance of length: +/- 1.0mm for each piece end product

|

| 6 | Computer Control Cabinet | - Programmable setting of profile length and quantity

- Operating system language: English and Chinese

- Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

- Computer used to control length & quantity. Machine will

automatically cut to length and stop when required quantity is

achieved

- Length inaccuracy can be amended easily.

- Control panel: Button-type switch and touch screen

- Unit of length: millimeter

- PLC: Siemens

- HMI: MCGS

|

4. Packing & Delivery

- Deliver time: take goods after receive deposit 80 days

- Packing: suitable of ocean transportation

5. Warranty

- Warranty: 1 year warranty from date of shipment

- Guarantee:

1: Guaranteed against malfunctions due to manufacturing defects for

1 year after date of shipment. Repairs will be made free of charge.

2: Repairs will not be performed free of change even during the

guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after

installation

3:Air ticket, transportation cost, hotel, meals and 100$ per day

shall be for purchaser’s account if manufacturer’s engineer has to

be for installation new machine.