Zhangjiagang City Saibo Science & Technology Co.,Ltd |

|

Verified Suppliers

|

|

CZ Purlin Roll Forming Machine

C/Z Purlin as one of important section in PEB, in same machine can make C channel, C lip channel, Z purlin and Sigma section. and the web & flange all automatic adjustable by servo motor to get high accuracy. And we give gear box for drive; Change C to Z in automatic also, n a real sense to achieve full automation production

1.Main specification

| No | Specification of the material | |

1

| Suitable Material | Carbon steel and Galvanized steel |

2

| Width of the raw material | Based on the purlin sizes. |

| 3 | Thickness | 1.5mm-3.0mm |

2.Specification of Components

| No | Technical Specification & Remark | |

| 1 | Manual Un-coiler

|

|

| 2 | Leveling part

|

|

| 4 | Main Roll Forming Machine

|

|

| 5 | Machine structure:

|

|

| 6 | Hydraulic cutting system

|

|

| 7 | Hydraulic System

|

|

| 8 | Computer Control Cabinet

|

|

| 9 | Out table

|

|

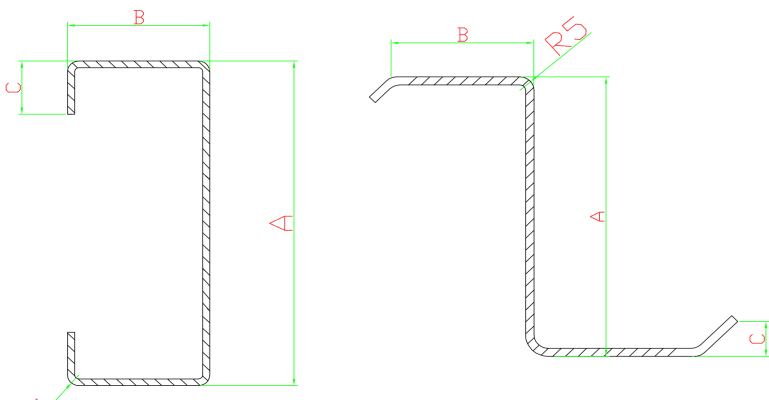

3.Profile drawing:

4.The Chart of Process Flow

Un-coiler—Leveling —Pre-cutting—Punching—Roll Forming—Post Cutting—out table

5. Machine pictures for reference

6. Warranty

1: Guaranteed against malfunctions due to manufacturing defects for 1 year after date of shipment. Repairs will be made free of charge.

2: Repairs will not be performed free of change even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

3:Air ticket, transportation cost, hotel, meals and 80$ per day shall be for purchaser’s account if manufacturer’s engineer has to be send to purchaser’s factory to maintain the machine during the guarantee period.