Zhangjiagang City Saibo Science & Technology Co.,Ltd |

|

Verified Suppliers

|

|

Post cutting Steel Stud Roll Forming Machine With 3T manual decoiler 0.9mm

Normal Speed Stud Roll Forming Machine

1. Composition of machine

Manual Un-coiler……………………………………… 1 unit

Roll forming main machine……………………………1 unit

Control panel…………………………………………..1 unit

Hydraulic station…………………………………… …1 unit

Out table ………………………………… ……………2 unit

2. Machine Detailed Parameters

| Coil width

| According the profile |

Rolling Speed

| 0-15m/min |

Rolling Thickness

| 0.9mm Galvanized steel |

Control System

| PLC |

Un Coiler

| 3 ton manual un-coiler |

Roller Stations

| 12 stations+1 station of film system |

Roller Material

| 45 forge steel, surface with chrome |

Shaft Material and DIA

| ¢56mm, material is 40CR, quenched and tempered |

Maim Motor Power

| 4KW |

Hydraulic Station Power

| 4KW |

| Cutting type | Hydraulic cutting, 4kw

|

Material Of Cutting

| Cr12, quenching 58-62℃ |

Tolerance

| 3m+-1.5mm |

| Electric Source | 380V, 50HZ,3 phase According to customer’s require |

Way Of Drive

| By chain |

Color Of The Machine

| Yellow and blue |

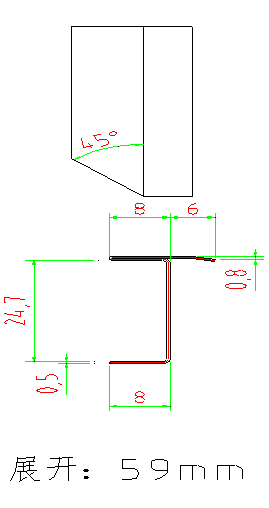

3. Profile drawing

4. The Chart of Process Flow

Uncoiling→Feeding material into machine→Roll forming→Rectify→Cutting→Out table

5. Specification of Components

(1) 3T Manual Un-coiler

(2) Main Roll Forming Machine

Roll station: 12stations+ 1 station of film system (according to the final design

Material of roller: 45#forge steel, coated with chrome

Material of main shaft: 40cr diameter roller: Ф56mm

Main power: 4kw

Forming thickness: 0.9mm, galvanized steel

Transmission: By chain

(4) Post cutting system

(5) Computer Control Cabinet

6. FAQ

1) Q: Are you manufacturer or trading company?

A: We are manufacturer and trading company .

2) Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are optional.

3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas services by skillful technicians.

4) Q: How does your factory do regarding quality control?

A: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

5) How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) We welcome you visit us and test machine by yourself in our factory.

6) Q: Do you have this roof panel roll forming machine in stock?

A: No, machine is made to order.