Zhangjiagang City Saibo Science & Technology Co.,Ltd |

|

Verified Suppliers

|

|

Wire-electrode cutting Stud Roll Forming Machine, Post cutting 4KW

1. Specification of the material

| 1 | Suitable Material | Galvanized steel |

| 2 | Width of the raw material | Acording to the final profile |

| 3 | Thickness | 0.9mm |

2. Machine Detailed Parameters

| Roll Forming

| Steel stud roll forming machine

|

| Machine structure

| Wire-electrode cutting structure |

| Total power | Motor power-4kw Hydraulic power-4kw |

| Roller stations |

bout 12 stations + one station for rectify >

|

Productivity

| 0-15m/min |

Drive system

| By chain |

Diameter of shaft

| ¢56mm solid shaft |

Voltage

| 380V 50Hz 3phases (Customized) |

Color Of The Machine

| Yellow and blue |

Deliver Time

| 70 days |

Terms Of Payment

| 30%T/T 70% pay before shipment |

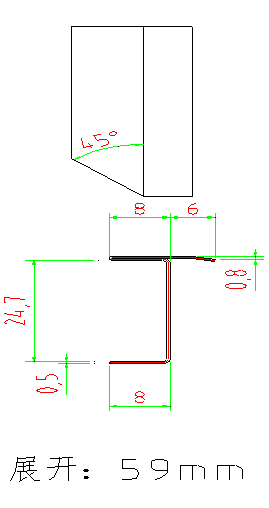

3. Profile drawing

4. The Chart of Process Flow

5. Specification of Components

(1) 3T Manual Un-coiler

(2) Main Roll Forming Machine

6. Main Features

1. Simple structure in linear type ,easy in installation and maintenance.

2. Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

3. Running in a high automatization and intellectualization, no pollution

4. No need foundation, easy operation

1: Guaranteed against malfunctions due to manufacturing defects for 1 year after date of shipment. Repairs will be made free of charge.

2: Repairs will not be performed free of change even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

3:Air ticket, transportation cost, hotel, meals and 80$ per day shall be for purchaser’s account if manufacturer’s engineer has to be send to purchaser’s factory to maintain the machine during the guarantee period.

8. Installation and training

a. If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

b. Without visiting, we will send you user manual and video to teach you to install and operate.

C. If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.