Zhangjiagang City Saibo Science & Technology Co.,Ltd |

|

Verified Suppliers

|

|

Saibo is a manufacturer and supplier of automatic pipe welding machines used by manufacturers, fabricators, and contractors. The common factor with all Saibo pipe welding customers is the need to make repeatable full penetration pipe welds meeting industry code standards. As more than 80 percent of welding costs are labor and overhead, automating pipe welding provides cost-effective productivity improvement.

Pipe welding machines are of four types. These; butt welding

machines, electrofusion welding machines, hand extruders, and plate

butt welding machines. Butt welding and electrofusion welding

machines are used in pressurized lines, hand extruders, and plate

welding machines are used in applications such as tanks, tanks,

pools with non-pressure lines.

1-Tube machine

2-Easy to operation

3- PLC control system

4-High speed

5: High Frequency Welded pipe making machine

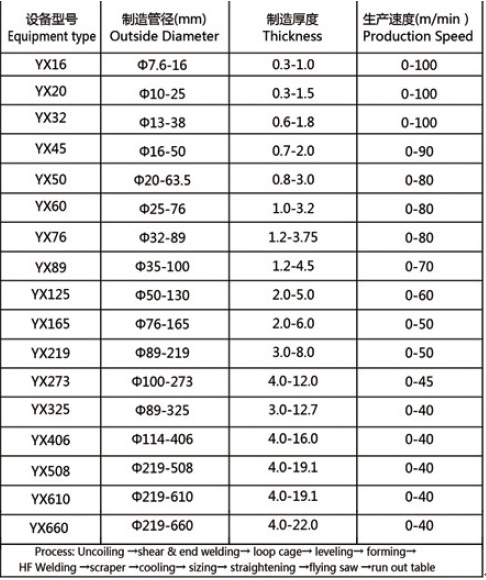

Description Capacity:

1,Pipe ID: 13mm-38mm

2,Thickness:0.6mm-1.8mm

3,Speed:0-100m/min

Double-head uncoiler

Briefing: Rotary type to change coils easily with a pneumatic brake

Parameters:

(1)The max. weight of coil:2000kg

(2)The inside diameter of coil:450-520mm

(3)The max. outside diameter of coil :1600mm

(4)The max .width of coil: 120mm

Mechanical segments

1. Steel strip revolving bracket

2.Double-roller feeder

3.Horizontal accumulator of helix metal strip

Power configuration

1. Motor of horizontal accumulator of helix steel strip 5.5kw(AC

motor)

2.motor of double-roller feeder 5.5kw(AC motor)

3.main motor power: 75kw

4. high frequency power: 100kw

Computer-controlled flying saw

A. Power of automatic controller: 7.5kw

B. Automatic tracking machine

1.The max .diameter to be cut :Φ38mm

2.The range of cutting length :4m-7m

3.The max. wall thickness to be cut :1.8mm

D. Power of the saw: 7.5kw

E. Accuracy of the cutting length :within±0.3mm

Discharging table

Conveyed on the rolling way ,reversed pneumatically(with 2.2kw

6classes motor)