Xiamen New KaiHang Machinery Co., Ltd |

|

Verified Suppliers

|

|

Beam Storage Rack Upright Roll Forming Machine PLC Control System

Application of Rack Upright Roll Forming Machine:

The upright roll forming machine is widely used for shelves in Hotels, Building Material Shops, Manufacturing Plant, Machinery Repair Shops

Quick Detail of Rack Upright Roll Forming Machine :

Description/Technical Parameter details of complete line:

Hydraulic system to expand coil inner hole, four palms

Motorized driving coil rotation, auto stop/start control, 2.2KW

Load capacity=2Ton

Coil width: 200mm

Coil Inner-diameter: Φ510±30mm

Equipped between the roller feeder and the press

Lubrication for punching tools and the roll former

Strip width: Max. 200, thickness: 1.5-2.0mm

Servo motor: YASKAWA, 1.3KW

Capacity: 80 tons

Chinese Brand: YANGLI

| Items | Specification | unit | Parameters |

| 1 | Nominal Capacity | Kn | 800 |

| 2 | Nominal stroke | mm | 5 |

| 3 | Slide stroke | mm | 140 |

| 4 | SPM(Variable Option) | Min-1 | 50-70 |

| 5 | Max. Die height | mm | 320 |

| 6 | Die height adjustment | mm | 80 |

| 7 | Between slide center and frame | mm | 300 |

| 8 | Bloster(FB×LR) | mm | 580×1000 |

| 9 | Bolster thickness | mm | 120 |

| 10 | Bed opening (FB×LR) | mm | 390×520 |

| 11 | Slide area(FB×LR) | mm | 420×560 |

| 12 | Shank hole(Dia.×depth) | mm | 50×80 |

| 13 | Between columns | mm | 640 |

| 14 | Motor Power | Kw | 7.5 |

| 15 | Air Pressure | Mpa | 0.55 |

| 16 | Net Weight | KG | 7000 |

| 17 | Gross Weight with iron pallet | KG | 7300 |

Wall plate frame design, thickness of wall plate is 18mm

18 stages to form

Rollers manufactured from Cr12, heat treatment

Shafts Diameter=ф75mm

Main motor =11KW

Non-Stop-to-Cut, post Cut, slug breaker

Cutting tool material: Cr12, Heat treatment

The cutting carriage is movable on smooth rails

Hydraulic group, pump motor 4KW

Siemens brand PLC and touch screen, Schneider brand Inverter, Omron encoder

Cut-to-length tolerance≤±1mm

Control Voltage 24V

Pneumatic un-loading device

3 meters Length

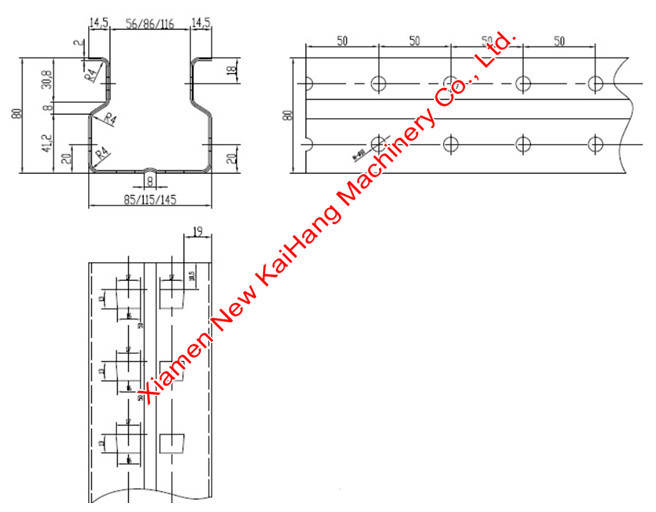

Profile Drawing/Layout/Equipment reference pictures: