Xiamen New KaiHang Machinery Co., Ltd |

|

Verified Suppliers

|

|

Reliable corrugated steel metal roof panel machine

Features:

Like another popular metal sheet machine, IBR sheet roll forming machine, corrugated sheet roll forming machine makes metal roofing and siding panels from the materials of 0.3-0.8mm thickness and 914-1250mm widths.

And it consist of un-coiler, entry bench and manual pre-shearing device, roll former and cutting device and product rack and PLC control systems

Quick Detail:

Machine list:

Description/Technical Parameter details of complete line:

Hydraulic system to expand coil inner hole, Pump motor: 3KW

Coil Inner-diameter= 510±30mm

Load Capacity: Max. 5 Tons

Coil Width Max. 1250mm

Taper wedge expand type

Driving motor to turn the coil, 3KW,

Manual frequency speed control

Smart cut control

To cut off the end of the final piece of sheet only

Working thickness: max. 0.8mm

| Suitable roll forming material | Pre-painted coil |

| Thickness | 0.4mm-0.8mm |

| Coil input width | 1250mm |

| Carriage Frame design | Wall-plate-frame-design /New-stand-frame-design |

| Roll forming stages | 20 stages |

| Roller material | 45# steel, CNC lathes, Hard Chrome Coated |

| Shafts Diameter | Φ75mm |

| Main motor power | 7.5Kw with reducer |

| Roll forming speed | 18m/min (Higher speed is available, depends on the specification required by the buyer) |

| Electric Voltage Standard | 380V/50Hz/3PH or as the customer's requirements |

| Major Color of Machine Painted | RAL 5015(Blue) or as per customer’s requirements |

Stop to cut, Post cut, No Blanking cut

Cutting tool material: Cr12, Heat treatment

Total two sets of cutting blades required

Hydraulic Group, Pump motor =4KW

Siemens brand PLC and touch screen, Schneider/ Shihlin/ Delta brand Inverter, Omron encoder

Cut-to-length tolerance≤±1mm

Control Voltage 24V

Packing standard:

Nude cargoes for roll former

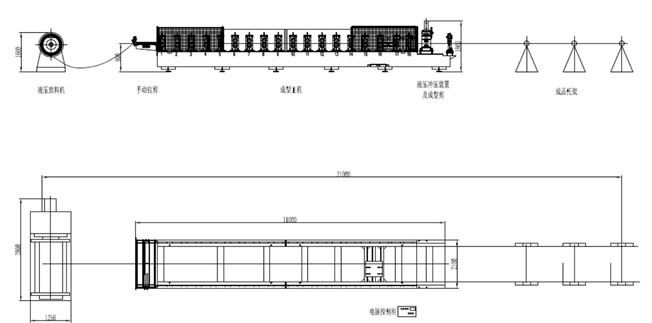

Profile Drawing/Layout/Equipment reference pictures: