Xiamen New KaiHang Machinery Co., Ltd |

|

Verified Suppliers

|

|

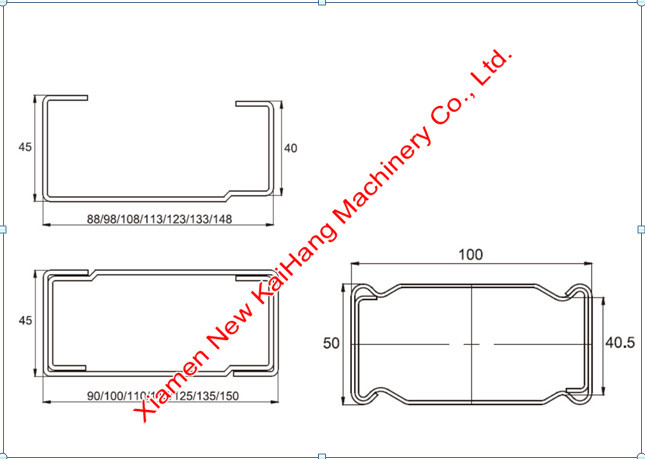

Boxbeam panel forming machine, cold rolled, galvanized steel

Quick Detail:

Application:

The box beam as main part together with upright, Uni, L slot and box panel is the complete shelves systems

The difference between C and beam is that the beam is two C section joint together

So, there are two parts for the roll former, one is to form 95% shape C section and 3 stages of roll former to joint them together to make the box beam

Machine list:

Description/Technical Parameter details of complete line:

Un-powered; Load capacity= MAX.5Ton

Hydraulic system to expand coil inner hole, Pump motor: 3KW

Coil inner–diameter=510+/-30mm

Coil Width= MAX.600mm

Mandrel rotation: Draft type

Pre-Level Device with 4 over 3 shafts to remove the Coil-set

Share the same motor with the roll former

| Suitable roll forming material | Color steel sheet or galvanized steel sheet |

| Thickness | 1.5-2.0mm |

| Carriage Frame design | wall-plate-frame-type |

| Rolling mills forming stages | 15 stages |

| Roller material | GCr15, heat treatment, hard chrome coated |

| Shafts Diameter | Φ75mm |

| Main motor power | 11Kw |

| Production speed | 12m/min |

| Hydraulic group power | 5.5Kw |

| Material of cutting blade | Cr12, heat treatment |

| Electric Voltage Standard | 380V/50Hz/3PH or as request |

| Major Color of Machine Painted | RAL 5015(Blue) or as request |

Control the quantity & cutting length automatically

Combined with: Siemens brand PLC and Touch Screen

Schneider brand Inverter, Omron encoder, etc

Cut-to-length tolerance≤±1mm

Control voltage 24V

Profile Drawing/Layout/Equipment reference pictures: