Botou Golden Integrity Roll Forming Machine Co., Ltd |

|

Verified Suppliers

|

|

USA CANADA MARKET CLIP LOCK STANDING SEAM METAL ROOF ROLL FORMER STANDING SEAM METAL ROOF MACHINE

1. Description of Popular in USA CLICK Lock Standing Seam Roof Panel Roll Former:

2. Technical details of Popular in CLIP LOCK STANDING SEAM METAL ROOF ROLL FORMER

| 1 | Raw material | Aluminum magnesium manganese plate, Titanium zinc plate,or Color steel plate |

| 2 | Material thickness | 0.4-1.0mm |

| 3 | Coil strength | Q235mpa |

| 4 | Coil width | As required |

| 5 | Main power | 2.2KW |

| 6 | Hydraulic station | 2.2KW |

| 7 | Main frame | 5# square pipe welded |

| 8 | Side steel thickness | 16mm |

| 9 | Forming stands | 8stands, with assist rollers |

| 10 | Shaft diameter | 45mm |

| 11 | Roller material | 45# steel, CNC fine machining, Chrome coated, Brushed and polished, the surface finish reaches the mirror standard |

| 12 | Forming speed | 0-15m/min, Frequency to adjust speed |

| 13 | Driving method | Motor drive, chain driving, part by gear |

| 14 | sprocket chain | 12A chain, Part of the upper and lower by gears |

| 15 | Shearing method | Stop to cut |

| 16 | Hydraulic brand | Taiwan Kexin Motor, Solenoid Valve Beijing Huade, Taiwan High Precision Gear Pump |

| 17 | Working pressure | Working pressure 10mpa,max pressure 16Mmpa |

| 18 | Electrical control system | Human-machine interface + button + touch screen (Xunjie) |

| 19 | Length counting method | Rotary encoder (Omron, Japan) length measurement |

| 20 | Control method | PLC Frequency conversion (Japan Panasonic) operation |

| 21 | Appearance color | Surface spray paint, blue + black + orange red match, or as required |

| 22 | Power | 220V 50HZ 3ph or as required |

| 23 | Main machine weight | About 1200 kgs |

| 24 | Main machine dimension | About 2800*1200*1400mm |

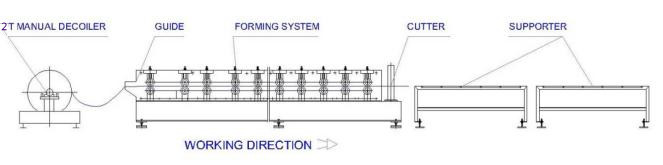

3. Production Flows of Popular in USA Snap Lock Standing Seam Roof Panel Roll Former

Uncoiling the sheet---Infeed guiding--Roll forming----Measure length---Cutting the panel--panels to the supporter

4. Main components of Popular in USA Snap Lock Standing Seam Roof Panel Roll Former

| Decoiler | 1 Set |

| Guiding Equipment | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

5. Application

This machine is widely used in the production of the roofing panel building.

9. Advantages

· Germany COPRA software design

· 5 engineers with more than 20 years experience

· 30 professional technician

· 20 sets advanced CNC production lines on site

· Passionate Team

· Installation engineers can reach your factory within 6 days

· 1.5 years maintenance and whole life technical support

10. Our service

A. Foreign debugging

If you need, we will arrange our professional engineers to help you install and debug the machines well. Buyer should pay $60 per day

B. Guarantee period

The warranty will be maintenance, maintain in the guarantee period of 18 months starting from delivery. Because of the quality of equipment during guarantee period, we will provide the parts free of charges, which is in the conditions of correct operation. (Natural disasters or factors which can’t forced by human are excluded).

C. Training

During installation and adjustment of the equipment, our engineers shall provide the training to

buyer’s personnel request to operate and maintain the equipment. Including foundation construction, electrical works, hydraulic oil, safe operation and non-standard safety items, testing material and etc.

D. Lifetime services

Life time services to every customer.

Welcome to contact with us!