Botou Golden Integrity Roll Forming Machine Co., Ltd |

|

Verified Suppliers

|

|

Portable Standing Seam Self Lock Metal Steel Roofing Clip Panel Roll Forming Machine

1. Description of standing seam snap lock roll forming machine:

The Clip Lock Snap Lock Standing Seam Metal Roofing Panel Forming Machine is used to make unexposed screw roof sheet.Firstly, the standing seam roof panels have a concealed fixing or seaming method by turning up the edges of two adjacent panels, and then folding or interlocking them. In this way, the seaming or fixing parts are invisible, and therefore sometimes we called the panels concealed fixing panels! The material thickness varies from 0.4-0.8mm,in some places such as USA,they use copper as raw material. But some other concealed fix standing seam roofing, likebemo roof sheet are thicker from 0.8-1.2mm.

2. Technical details of standing seam snap lock roll forming machine:

| Machine Specifications | |

| Weight | About 1tons |

| Size | About 2.7M* 1.4 M*1.4M(length x width x height) |

| Color | Main color: blue or as your requirement |

| Warning color: your requirement | |

| Suitable Raw Material | |

| Material | Galvanized Steel Coils |

| Thickness | 0.5-0.8mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 8 |

| Diameter of forming rollers shafts | 70mm |

| Roll Forming Speed | 3-5m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 5kw |

| Hydraulic unit motor power: 4kw | |

| Electric voltage | According to customer’s requirement |

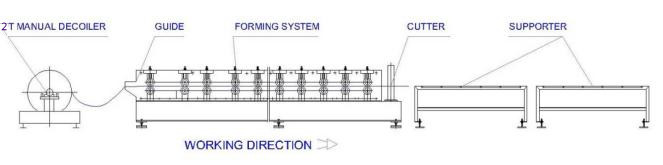

3. Main components of standing seam snap lock roll forming machine

| Decoiler | 1 Set |

| Guiding Equipment | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

4. Production Flows of standing seam snap lock roll forming machine

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

5. Advantages of standing seam snap lock roll forming machine

6. Application of standing seam snap lock roll forming machine

This machine is widely used in the production of the roof wall steel construction and so on.

7. Product photos of standing seam snap lock roll forming machine

8. FAQ

Q. How long can the machine be built?

A: Generally speaking, the machine takes about 40 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q. Why are your prices higher than others?

A: Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate, and have a longer service life. The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.