Botou Golden Integrity Roll Forming Machine Co., Ltd |

|

Verified Suppliers

|

|

High speed 10-12m/min cable tray roll forming machine Fully automatic cable tray making machine

1. Description of cable tray roll forming machine:

Our cable tray roll forming machine could produce wide range of sizes, commonly used width is 100-800mm, we can also customize according to your width, and automatic change by motors from one size to the other not only at width but also at height. Change size is very simple, the step is put your required data into touch screen and wait for few seconds. And other wise innovation is that one machine could make cable trays and covers of corresponding size. Change time is only 30 minutes, it's easy to operate , this machine can save cost and save space.

Our factory is manufacturing high quality cable tray roll forming machine, and regularly exported to South Africa, Zambia, Rwanda, Dubai, Poland, Saudi Arabia, Israel, Philippines, Thailand, Canada

2. Technical details of cable tray roll forming machine:

| Machine Specifications | |

| Weight | About 10tons |

| Size | About 36m*3m*1.3m(length x width x height) |

| Color | Main color: blue or as your requirement |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Steel Coils |

| Thickness | 0.8-2.5mm |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 26 stations |

| machine frame | 400H steel 26mm |

| Roll Forming Speed | 10-12m/min |

| Forming rollers material | 40Cr heat treatment HRC55-60, hard chrome plating on the surface |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 5.5KW*4 |

| Electric voltage | According to customer’s requirement |

3. Main components of cable tray roll forming machine

| Hydraulic Decoiler | 1 Set |

| Guiding Equipment | 1 Set |

| Leveling Equipment | 1 Set |

| Punching part | 1 Set |

| Roll Forming Unit | 2 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

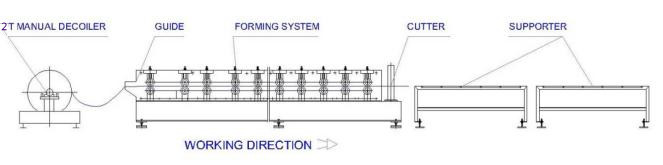

4. Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

5. Advantages

About the company:

1. Our company has 25 years of production experience, which can

guarantee the quality of the machine

2. Our company has 5 warehouses, which store raw materials

separately, and will not delay delivery

3. Our company has professional after-sales service. If you don't

know anything about the machine, you can find our after-sales

service at any time.

About the machine:

1.CNC machine to produce the machine rollers, which can guarantee

the quality of the machine wheels

2. The large frame is produced by our company and will not be

deformed

3.Chain use 1.5 inch

6. Application

This machine is widely used in the production of the cable tray line.

7. Product photo

8. FAQ

Q:Can you customized our profile?

A:Yes dear.Our company have more than 25 years exoerience,5 engineers with more than 20 years experience design your profile.

Q:How can I trust you that machines pasted testing running before shipping?

A:1) We record the testing video for your reference. Or,

2) We welcome you visit us and test machine by yourself in our factory.

Q:What is your payment terms?

A:30% as the deposit by T/T in advance,70% T/T as balance after you inspect the machine before shipping.

We also accept 100% L/C at sight

We can accept Western Union payments.

Other payment terms you want to pay, please let me know and i will check and reply you.

Q:When will you delivery thye machine after i place the order?

A: After we get down payment,we will arrange production.About 30-45 days for delivery.

Q:What will you do if the machine broken?

A:We provide 12 nonths free warranty and free technical support for the whole life of any machine.

If the broken parts can’t repair,we can send the new parts replace the broken parts freely.If it is beyond the warranty period,we can negotiable to solve theproblem,and we supply the technical support for the whole life of the machine