Botou Golden Integrity Roll Forming Machine Co., Ltd |

|

Verified Suppliers

|

|

0.3-0.8 mm Color Coated Steel Metal Glazed Roof Tile Panel Making Roll Forming Machine

1. Description of glazed tile roll forming machine:

This machine is used to produce roofing products for construction, housing, etc. The material of the machine rollers is No.45 steel, coated with chromed treatment, the middle plate of the machine frame is 16mm, and the shaft diameter is 70mm. The machine will not be deformed after a long time of use. The thickness of the raw material can be 0.3-0.8mm, if you have other demands, please contact me, we can customize.

Our company are professional product the metal glazed tile roll forming machine manufacture, It’s also named metal glazed tile roof roll forming machine, steel glazed tile roof sheets roll forming machine, color steel glazed tile roof panel roll forming machine, roll forming machine, steel glazed tile roof theets roll forming machine.

2. Technical details of glazed tilel roll forming machine:

| Machine Specifications | |

| Weight | About 5tons |

| Size | About 1.5m*1.5m*1.3m(length x width x height) |

| Color | Main color: blue or as your requirement |

| Warning color: your requirement | |

| Suitable Raw Material | |

| Material | Galvanized Steel Coils |

| Thickness | 0.3-0.8mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 18 |

| Diameter of forming rollers shafts | 70mm |

| Roll Forming Speed | 3-5m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 5kw |

| Hydraulic unit motor power: 4kw | |

| Electric voltage | According to customer’s requirement |

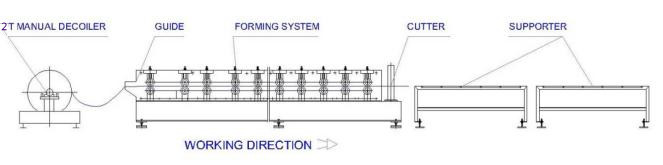

3. Main components of roof panel roll forming machine

| Decoiler | 1 Set |

| Guiding Equipment | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

4. Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

5. Advantages

6. Application

This machine is widely used in the production of the roof wall steel construction and so on.

7. Product photo

8. FAQ

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control,

including the laying of raw materials, processing rolls and other

parts, processing, assembly, testing and packaging on the roll

surface and shaft.

Q: What can you do if the machine broken?

A: Our machine is warranted for 18 months. If the damaged part

cannot be repaired, we can send a new part to replace the damaged

part, but you will need to pay the courier fee yourself. If the

warranty period is exceeded, we can resolve the issue through

negotiation and we provide technical support for the entire life

cycle of the device.

Q. How to get a quotation?

A: 1. Give me the profile drawing and the thickness of your material it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don't have your own profile drawing, we can recommend some models according to your local market standard.